US 3D printer manufacturer nano3Dprint has launched its MatDep Pro 3D multi-material and electronics printer.

The MatDep Pro caters to a broad audience, including engineers, entrepreneurs, tech leaders, and advanced at-home designers. A limited batch of 50 units is accessible to consumers through an application process. Priced at $8,800, the 3D printer necessitates a $500 refundable deposit. According to Ramsey Stevens, nano3Dprint’s CEO, the MatDep Pro plays a pivotal role in reducing cross-contamination, a crucial factor in preventing disruptions in the conductive path. “The independent motion of the print heads prevents cross-contamination and offers better print quality, speed, and reliability.”

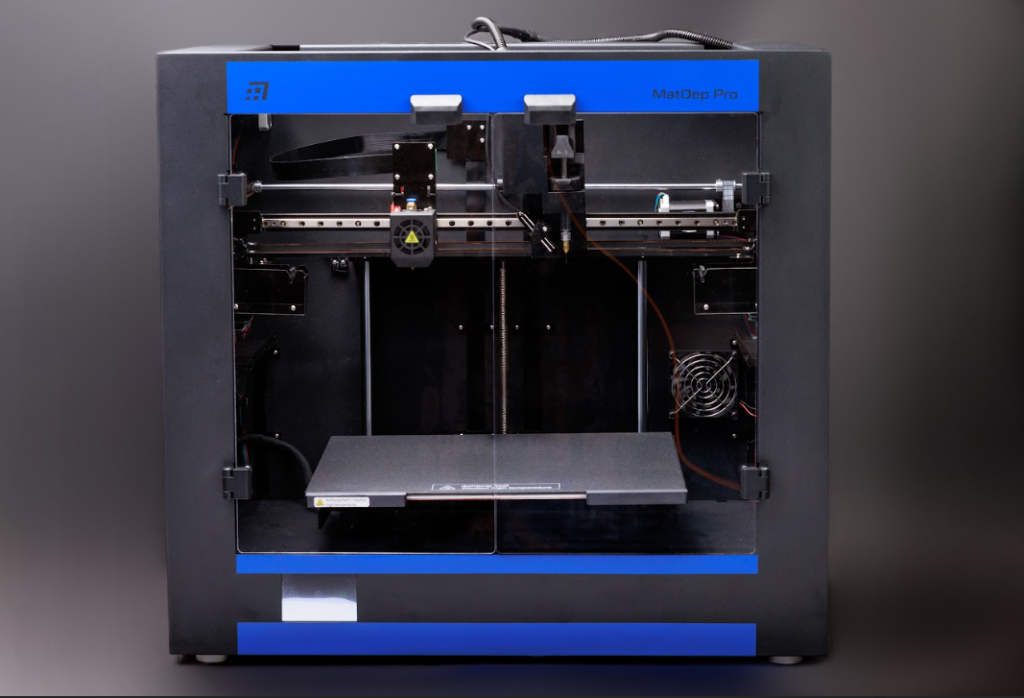

MatDep Pro: Advanced 3D printing for functional electronics

The MatDep Pro, nano3Dprint’s largest system at 360 x 250 x 200mm (14.17 x 9.84 x 7.87 inches), enables the developing of electronics with dynamic features like conductivity, magnetism, or responsiveness. It also supports the development of devices with locally customized composition, structure, and properties. This system’s versatility extends to applying materials to diverse substrates, enabling the creation of electrical connections and patterns with electrodes, wires, or traces seamlessly integrated into fused deposition modeling (FDM) designs.

The MatDep Pro’s FDM extruder and materials dispensing system provide a seamless method for integrating conductive and functional inks/pastes into a 3D design. This system enables users to print with plastics like ABS and PLA using the extruder, all while incorporating advanced materials, including highly conductive inks like gold or silver, as well as versatile pastes such as silicone and polymers.

Operating independently, the extruder and materials dispensing system enhance the precision and accuracy of the prints. The MatDep Pro incorporates several key features, such as an industrial linear guide ensuring stable and precise movement control, a flexible magnetic build mat for effortless print removal, and nozzle cleaning stations for both the FDM extruder and materials dispensing system. Moreover, the printer’s robust steel construction for the housing enhances structural stability, reduces vibrations, and enables more precise movement of the print head.

“A major benefit of 3D printing with functional materials is creating electronics that can conform to different shapes and surfaces. This opens up new possibilities in wearable technology, smart textiles, biomedical devices or conformal supercapacitors, for example. Users can design and produce their own electronics on-demand, without the need for expensive and specialized equipment or facilities,” Stevens added.

Technical specifications and pricing

| Features | |

| Extrusion/Dispensing | Single 1.75 mm FDM (Extrusion Position 1)with Materials Dispensing System(Dispensing Position 2) |

| Independent Motion | The extruder and materials dispensing system assemblies move independently. Both printheads are automatically wiped clean after use |

| Continue Printing AfterPower Cut | Yes |

| Industrial Linear Guide | Stable and precise movement control |

| Connectivity | USB/SD and Card/WiFi |

| Software | |

| Compatible with | Simplify3D, Repetier-Host, Cura, and Makerware |

| File Format | STL and GCODE |

| Operating System | Windows, Mac, Linux |

| Materials Dispensing System | |

| Syringe Size | 3 ml |

| Nozzle Size | 14 to 30 Ga (1.6 mm to 150 µm)Higher Resolution Available: 30 Ga, 32 Ga, 34 Ga |

| Materials Support | Functional Pastes and Inks, Conductive NanoParticle Inks, Resistive, Dielectrics, Magnetic, Thermo-Electric, Photovoltaic, and Graphene Solutions |

| FDM extruder | |

| Extruder Size | 0.4 mm (1.75 mm filament) |

| Materials Support | PLA, ABS, PETG, POM, Nylon (PA), PC,Carbon Fiber filament, Dissolvable filament(PVA, HIPS), and Flexible filament (TPU, PLA+) |

| Build | |

| Build Volume | 360 x 250 x 200 mm; 14.17 x 9.84 x 7.87 inches |

| Stage Material | Flexible Magnetic Build Ma |

| Extrusion Layer Thickness | 0.1-0.3mm |

| Positional Accuracy | XY axis: 0.011 mm; Z axis: 0.0025 mm |

| Extruder Diameter | 0.4 mm |

| Max. Extruder Flow Rate | 24 cc/hour |

| Printing Speed | 20-200 mm/s |

| Bed Temperature | Max 120℃ |

| Printing Temperature | Max 260℃ |

| Machine Dimensions | 630 x 430 x 625 mm |

| Machine Weight | ~ 92.5 lbs |

Who will win the 2023 3D Printing Industry Awards? Make your nominations now!

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows MatDep Pro 3D multi-material and electronics printer. Image via nano3Dprint.