Italian 3D printer manufacturer Prima Additive has unveiled three new machines at the Formnext 2021 trade show.

The first of which, the Double Wavelength Print Genius 150, packs dual 300W infrared and 200W green lasers, which are capable of working simultaneously to drastically reduce part lead times. With its second more industrial Print Genius 250, the firm has launched a 500W single-mode dual-laser system as well, that it says is more than powerful enough to unlock “high-productivity metal 3D printing” for users.

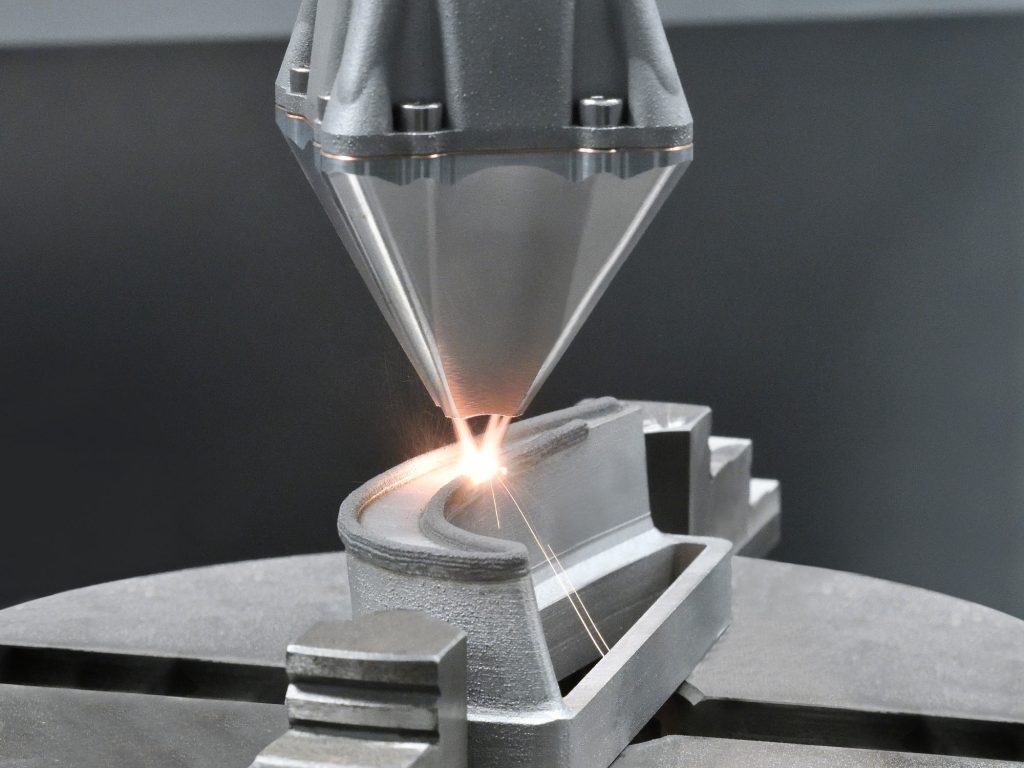

On the Direct Energy Deposition (DED) front, the company also launched the Laserdyne 811 at the show, an ultra-compact machine with an advanced controller that supports seven axes of simultaneous motion. As a result, the system is said to possess an extremely high ‘build ratio,’ potentially making it ideal for a variety of manufacturing, material development and component repair applications.

A growing powder bed portfolio

Utilizing the laser system manufacturing expertise of its parent firm Prima Industrie, Prima Additive specializes in developing 3D printers that help industrial manufacturers flex-up their production processes. To best achieve this, the firm markets a range of proprietary hardware and materials, as well as a suite of training, consultancy and design optimization services.

Prior to the launch of its new systems at Formnext, the company’s machine portfolio already included the entry-level R&D Print Sharp 3D printers, in addition to the larger-format Laser Next 2141. While the former LPBF machines feature very similar specs to Prima Additive’s original Print Genius units, the latter is built for DED production at scale, and has a colossal 4,140 x 2,100 x 1,020 mm build volume.

Since launch, the firm’s systems have found applications in the aerospace, energy, automotive, electronics, medical and education sectors, and with the launch of its new Print Genius and Laserdyne 811 3D printers, it says it’s now seeking to better address “major industrial sectors, where additive manufacturing is rapidly evolving.”

The makings of a ‘Print Genius’

Debuted at Formnext, Prima Additive’s Laser Powder Bed Fusion (LPBF) Print Genius 150 Double Wavelength incorporates a unique dual-laser set up, in which they can be configured to work alternately on the same build area. Using this feature, adopters are able to tweak their print parameters and find the best possible wavelength to optimize the radiation absorption of their materials.

When 3D printing steel, titanium, nickel or chromium-cobalt, for instance, users are able to deploy the machine’s infrared lasers, but they can then switch to green radiation when processing highly-reflective materials such as pure copper and aluminum.

Much like the conventional Print Genius 150, the Double Wavelength edition includes a 150 x 160mm cylindrical build volume too, but unlike the original, the new version can be fitted with upgrades, like a double preheating unit, coaxial pyrometer, dual monitoring cameras and an application-led laser beam-focusing system.

Prima Additive also showed off the new Print Genius 250 at its Formnext booth, a 258 x 258 x 350mm dual 500W laser machine that’s designed to produce ‘medium-sized’ metal parts at pace. Thanks to its integrated software and unique gas flow system, the 3D printer is largely able to achieve this, as it rapidly orientates components pre-production, and consumes minimal material during builds.

The Print Genius 250 also comes equipped with a dual-filter unit, which recirculates gas around the build area, and serves to minimize the number of parts that need to be replaced due to wear, furthering the system’s continuous manufacturing credentials.

In practise, the machine’s intelligent programming allows users to actively track and tweak its parameters in real-time as well, including those that directly affect its platform, materials and powder collection. This enables users to easily optimize their system for producing parts with a target use-case, which given its broad compatibility with high-hardness steels, could lend it molding applications.

Prima Additive’s 9.5-ton behemoth

Alongside the new additions to its Print Genius offering, Prima Additive also launched a new DED machine at Formnext: the 1100 x 800 x 600 mm Laserdyne 811. With an integrated controller that enables parts and subassemblies to be auto-loaded onto its build platform using robotics, the 9,550-kilogram unit is built for productivity, and is capable of reaching deposition speeds of up to 70cm3/h.

This build rate makes the machine ideal for research or industrial applications, while its built-in turntable lends it significant potential as a repair tool for larger components. Capable of continuously rotating at N x 360° clockwise or anti-clockwise on the vertical axis, and from -150° to + 150° on its diagonal axis, the table can be used to rebuild damaged tools or critical components up to 300kg in mass.

The Laserdyne 811 is also highly-flexible, given that its BeamDirector nozzles can be rapidly switched out, and replaced with additive, welding or drilling heads, allowing users to quickly customize it for addressing specific applications.

The machine’s laser set up can be tailored as well, with 1000W, 2000W and 3000W Yb laser sources available as standard, and the REAL_DED head compatible as an optional extra. Prima Additive’s more advanced patented deposition head is said to allow users to tweak their laser in real-time and double its spot size, effectively maximizing their part throughput.

More information about the REAL_DED deposition head can be found here.

Technical specifications and pricing

Those interested in Prima Additive’s Double Wavelength Print Genius 150, Print Genius 250 or Laserdyne 811 can request a quote from the firm’s website, but in the meantime, their technical specifications are as follows:

| Print Genius 150 Double Wavelength | Print Genius 250 | Laserdyne 811 | |

| Technology | LPBF | LPBF | DED |

| Build Volume | 150 x 160mm (cylindrical) | 258 x 258 x 350 mm | 1100 x 800 x 600 mm |

| Laser Type | 2 x 300W IR or 1x IR + 1x Green Fiber | 2x 500W Single Mode IR | Yb Fiber, CW Multimode, IR |

| Accuracy/Resolution | 0.02 – 0.12mm | 0.02 – 0.1mm | 25 µm |

| Build Rate | 2 – 50 cm3/h | 25 – 50cm3/h | up to 70cm3/h |

| Weight | 1800 kg | 2500 kg | 9550 kg |

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Prima Additive logo 3D printed onto a metal part. Photo via Prima Additive.