Precise Bio, a biotechnology company based in North Carolina, has established a dedicated ophthalmology business unit in its Winston-Salem facility. In addition to its 4D Bio Fabrication Platform, the unit aims to advance 3D bioprinting research for the eyes.

“As the first company to transplant a 3D printed corneal graft in animals, we are uniquely positioned to advance the use of bio-printed tissues in ophthalmology,” ays Aryeh Batt, Co-Founder and CEO of Precise Bio.

“Establishing a business unit dedicated to realizing this potential will support our future financing strategies and ensure that our financial resources are aligned with the tremendous power of our technology and intellectual property.”

Advancing 3D printed corneal grafts

According to Batt, the ophthalmology market has an estimated cumulative value of $10 billion. Precise Bio aims to accelerate the development of autologous cell sourcing, innovative bio-inks, and bioreactors, with an aim to create functional 3D printed organs.

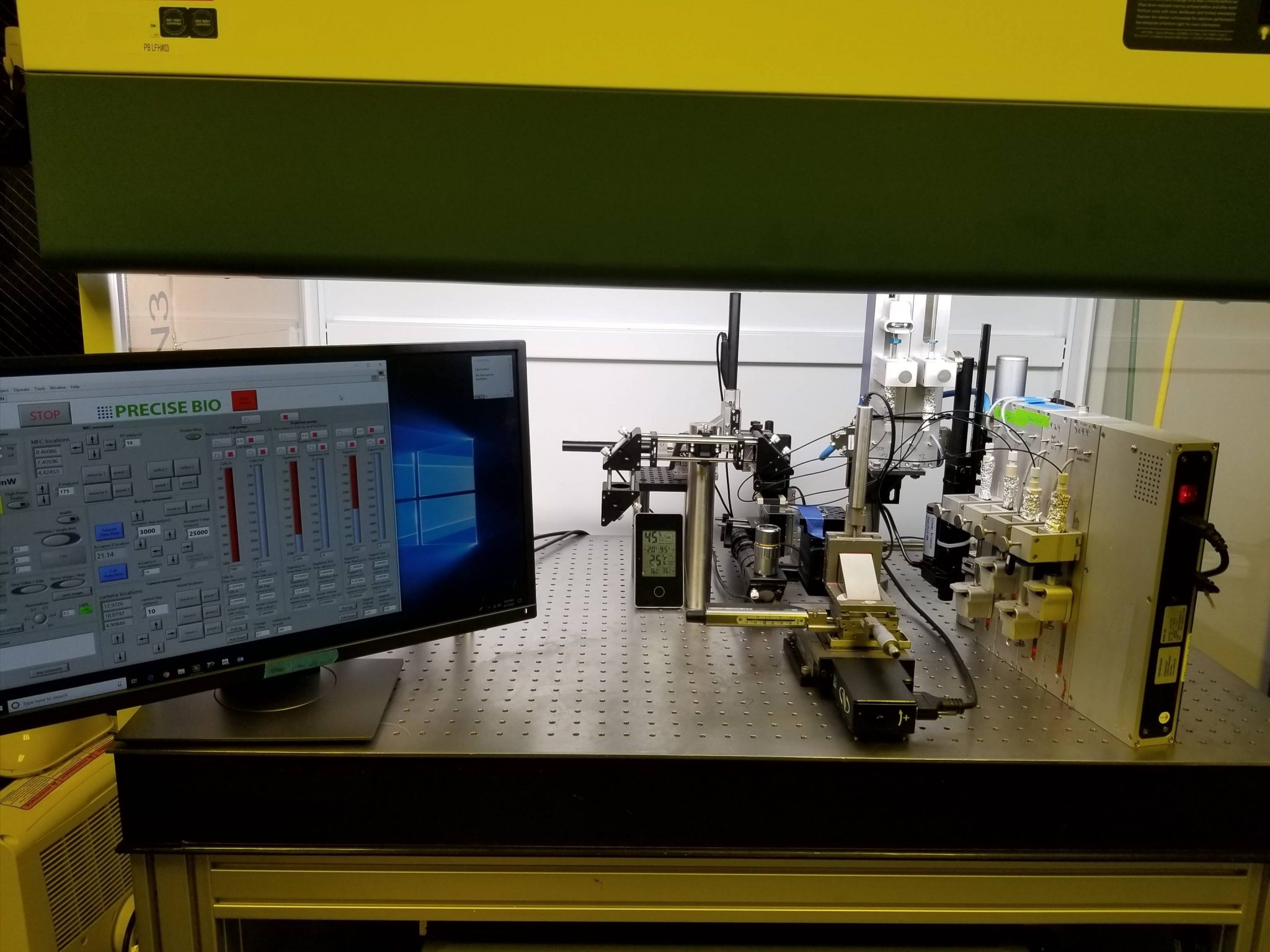

As a result, Precise Bio has developed a laser-assisted 4D bio-fabrication technology platform for cell expansion and the production of complex tissues in a highly reproducible manner. Shay Soker, Co-Founder of Precise Bio and Ph.D., Professor at the Wake Forest Institute of Regenerative Medicine (WFIRM) stated, “[Our] company’s technology overcomes multiple challenges in scalable, reproducible manufacturing of bioprinted tissues and organs, and positions Precise Bio for leadership in the field of regenerative medicine.”

“Precise Bio’s technology has the potential to truly transform the treatment of serious diseases, and to address the unmet needs in corneal replacement and other indications, which cannot be met by the limited number of donor tissues and organs.”

Batt added, “Based in part on the requests and suggestions from key audiences, we are currently pursuing different ophthalmic programs, two of which are being undertaken with collaborators.”

The human cornea program strives to advance the development of other organs and tissues for use in ophthalmic indications. This includes retinal patches, vision correction lenticules (porous outer plant tissue ), and solutions for ocular surface diseases.

3D printing and ophthalmology

Earlier this year, scientists at Newcastle University (NCL) successfully 3D printed human corneas for the first time. Following this, Dr. Song Hongxin, an ophthalmologist and researcher at the Beijing Tongren Hospital, China, 3D printed spectacles to help patients with deformed corneas.

Furthermore, the University of Sydney’s Save Sight Institute was awarded a $1.15 million (AUD) grant to progress commercialization of its 3D corneal biopen, capable of extruding bioink directly onto an eye to aid in the regeneration of cells on corneal ulcers.

For the latest additive manufacturing news subscribe to the 3D Printing Industry newsletter, find us on Facebook and like us on Twitter.

Looking for jobs in engineering? Search open opportunities and apply with 3D Printing Jobs. You can also make a profile to advertise your latest vacancies.

Featured image shows a macro view of the human eye, iris, pupil, eye lashes, eye lids. Photo via Shutterstock.