French biotechnology company Poietis, has announced the launch of a new 4D bioprinting platform. Titled Next Generation Bioprinting (NGB), the technology incorporates automation, robotics and sensors, to improve performance.

It is also to be realized in two new 3D bioprinters from the company: the NGB-R, for research applications, and the NGB-C, to meet future clinical needs of its partners.

Laser assisted 4D bioprinting

Poietis’ 4D bioprinting technology is a laser assisted process. In it, a pulsed laser is used to deposit microscopic droplets of cell-laden ink onto a substrate.

The 4D element of technology, as with typical 4D printing, is time – as in the time taken for layered droplets to develop into tissues after 3D bioprinting. By adopting 4D instead of 3D, Poietis differentiates itself from a growing bioprinting market, though time to culture is still required of all current cell-based 3D fabrication techniques.

Industry 4.0 ready bioprinting

With the new NGB platform, Poietis has integrated several Industry 4.0 driven technologies into its 4D bioprinting operations. As such, the platform has been upgraded with features to facilitate automation, the use of robotics, and multiple bioprinting techniques. Numerous online sensors have also been added for process monitoring, including a module for timelapse imaging of cell development at a microscopic level, or “cell microscopy.”

Fabien Guillemot, President and Chief Strategy Officer at Poietis, explains “We have upgraded the NGB platform to an automated robotic system to improve the standardization of manufacturing processes and the functionality of biological tissues.”

Addressing the importance of interplay between 3D design and machine capabilities, Guillemot also adds, “The combination of multimodal bioprinting with the acquisition and the online processing of printed cell images at cellular resolution will also ensure that what we design is what we print.”

The idea of the improvements, is to expedite the pre-clinical level of 4D bioprinting research, with a knock-on effect to the clinical and eventual marketability of artificially produced tissues.

Poietis, BASF and Servier

Poietis already has a cosmetics development partnership in place with BASF, the largest chemicals producer in the world. In addition, earlier in 2018 the company announced a liver 4D biopritning partnership with privately owned global pharmaceutical company, Servier Laboratories. In an interview regarding the announcement Bruno Brisson, the Poietis Co-Founder and Business Development Director, told 3D Printing Industry, “We believe 3D Bioprinters are more than robotic pipettes.”

Speaking on his company’s release of the NGB platform, Brisson said:

“In parallel with our first applicative developments on bioprinted tissues for in vitro models, we continue to evolve our business model to meet the expectations of tissue engineering specialists and biology researchers.”

For the latest 4D and 3D bioprinting news subscribe to the 3D Printing Industry newsletter, find us on Facebook and like us on Twitter. Looking for jobs in engineering? Search open opportunities and apply with 3D Printing Jobs. You can also make a profile to advertise your latest vacancies.

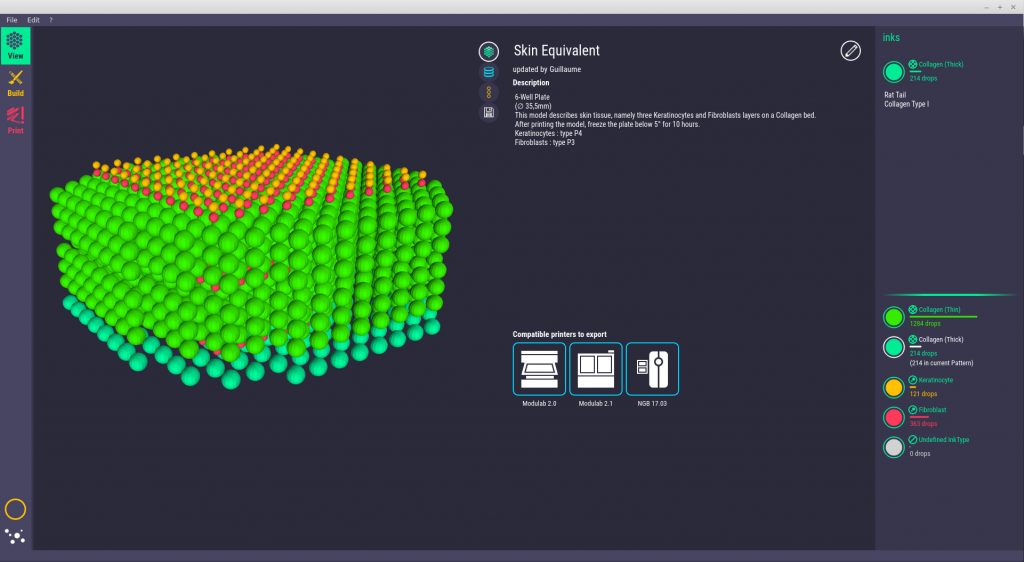

Featured image shows a build chamber of the Poietis NGB 4D bioprinter. Photo via Poietis.