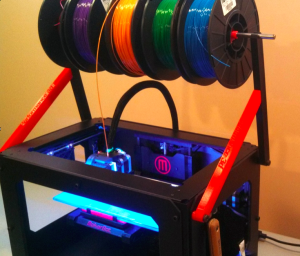

Makerbot’s Replicator 2 is one of the most widely used desktop 3D printers out there, with a vast community of 3D printing enthusiasts and researchers around the world using their machines. Being well balanced in the sense of price-capabilities, well-built using high quality materials, having good accuracy in the resulting models, and staying fairly light and compact, this little machine boasts a market edge in many regards.

However, for the tech-savvy and creative developers out there, it seems there is always room for improvement. As was the case for Scott and Jay for whom it came naturally as they were messing around with their own MakerBots.

Currently, there are a handful of products being sold at the Performance 3D online store that can be used in a variety of 3D printers. The first one is the aluminium arm stiffeners developed with the aim of dramatically reducing the arm’s deflection when loaded. They bolt to the side of the arm and decisively eliminate the annoying sagging that can lead to model building inaccuracies or failure.

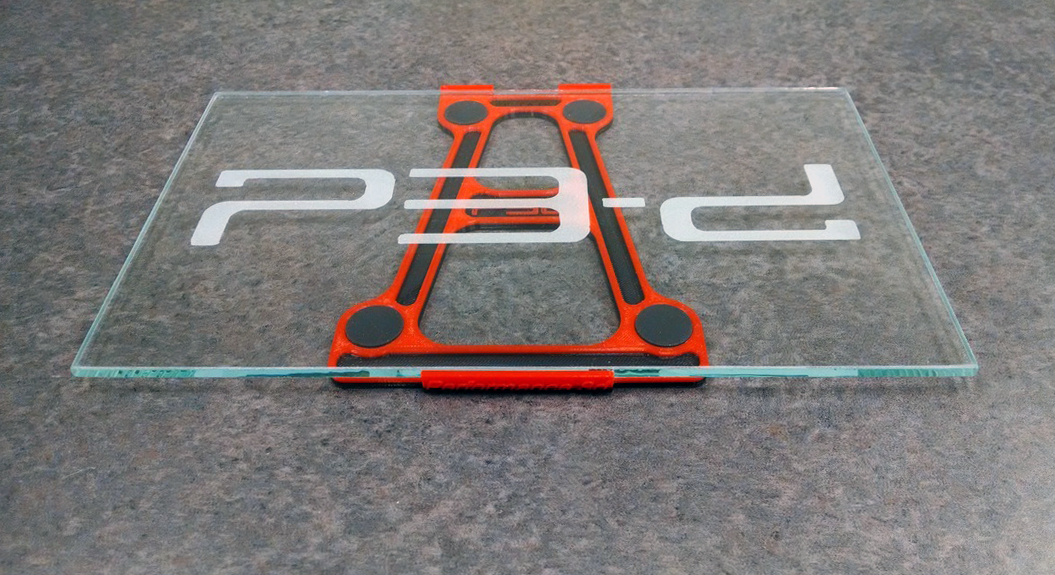

Another interesting part from Performance 3D is the ultra-flat glass build plate intended to replace the stock Replicator 2 acrylic plate that is usually warped out of the box. The glass plate comes with its own cool looking frame that helps centring the plate to the right position.

Other products include low friction high performing nozzles and build plate coverage painter’s tapes. More products aimed at enhancing a wider range of existing 3D printers are in the works and expected to be available soon, taking 3D printing to the next level, both in terms of a wider business potential and higher standards of performance.