Connecticut based PEKK specailist Oxford Performance Materials (OPM), has received the Accreditation of Foreign Medical Device Manufacturer (FMDM) from the Japanese Ministry of Health, Labour and Welfare.

OPM is known for pioneering the use of the polymer poly-ether-ketone-ketone (PEKK) for aerospace, industrial and biomedical applications, including 3D printing parts for Boeing’s CST-100 Starliner spacecraft.

In 2013 OPM also the first company to receive FDA 501(k) clearance for the manufacture of 3D printed polymeric implants.

Japan’s FMDM accreditation will help OPM as it seeks to expand into the broader Asian market.

Pioneering PEKK polymer with SLM 3D printing

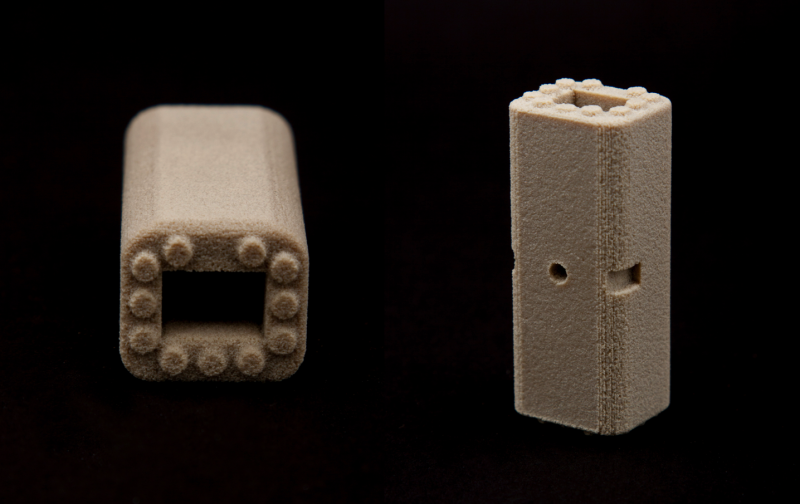

Medical applications at OPM are led by the company’s proprietary OsteoFab technology.

The technology is SLS based, and uses the OPM’s proprietary OXPEKK polymers, as explained further in an interview with OPM President and CEO Scott DeFelice.

Due to what DeFelice describes as their “very high purity, very high chemical resistance, and very high mechanical properties,” OsteoFab implants are used in a variety of orthopedic applications, including in the spine and cranium.

OXPEKK’s bone-like characteristics enables x-rays and bone on-growth, qualities that are leading medical service providers like Florida’s RTI Surgical to adopt OsteoFab 3D printed spinal implants over competing products, and the technology’s application for craniomaxillofacial operations.

A $5 billion market

Japan is the world’s second largest market for medical equipment and America’s most valuable export destination for medical devices. Approximately $5 billion worth of American medical devices and supplies are sold annually in Japan, accounting for a quarter of Japan’s total spending on medical devices.

DeFelice, “OPM started regular exploration of the Asian market 10 years ago in order to deeply understand the reimbursement environments, potential markets and commercialization opportunities,”

“This accreditation allows OPM to start an export program to initiate market development and advance our Asian business.”

Keep abreast of the latest industry news, subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Voting for the 2018 3D Printing Industry Awards is now open.

Looking for ways into 3D printing? Looking for talent? The 3D Printing Industry Jobs is live.

Protolabs is sponsoring the 2018 3D Printing Industry Awards design competition. Submit your entries now with the chance of winning a 3D printer.

Featured image shows The OsteoFab Patient Specific Cranial Device (OPSCD) from Oxford Performance Materials.