Functional prototypes are an important application for industrial 3D printing. Materials used in components for aircraft, automotive, electronics or sports – must be reliable and cost effective for product development.

For lightweight, high strength parts, the kind you’d find in F1 cars or the core-composites of snowboards, fiber reinforcements are a standout solution.

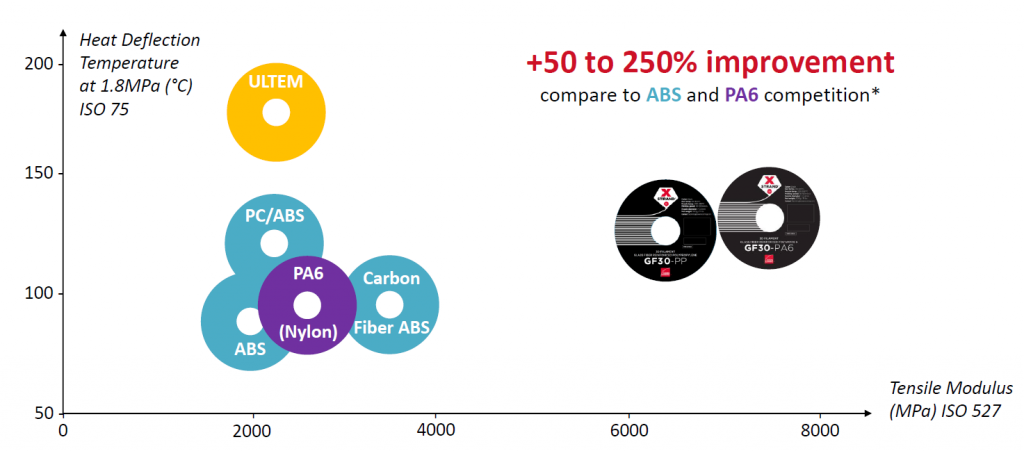

Owens Corning, a leader in fiberglass composites, has introduced a range of glass fiber reinforced filaments for FFF/FDM 3D printers. “Redefining additive manufacturing performance” XSTRAND™ filaments are a strong and resilient upgrade on standard or carbon-fiber filled ABS, or neat PP. The range of Owens Corning 3D printing filaments will be available from US-based distributors including IC3D and iMakr.

The first of the Owens Corning 3D printing filament range is GF30-PP, a polypropylene reinforced with fiberglass. In a case study at French ski-slope outerwear and equipment manufacturer Rossignol GF30-PP passed extreme alpine testing for a new range of mountain products.

Bringing composite material expertise to 3D printing filaments

Owens Corning was founded in 1938. Today its fiberglass material can be found in key insulating materials, providing insulation for commercial, industrial and residential properties. Its roofing products provide solutions for helping to protect houses and its fiberglass is used across hundreds of composite applications. Seeing the potential for higher performance composite materials in additive manufacturing, in 2016 Owens Corning made the decision to apply its expertise to create the XSTRAND™ range.

XSTRAND™ GF30-PP has 30% glass fiber content. This unique composition gives the material a number of outstanding, and often complementing properties. 3D printed XSTRAND™ GF30-PP produces parts that are high in stiffness and offer excellent resistance to temperature, chemicals and UV light.

The fiber content of the filament reduces warping/shrinkage that can occur in typical PP materials. The added fibers also boost the measured tensile modulus. offering between 50% and 250% improvement on ABS and nylon-based PA6 materials. In addition to an excellent tensile modulus, XSTRAND™ filament has good thermal performance properties, offering performance that is close to much higher cost unfilled thermoplastics.

3D printing functional prototypes

A recent 3D printing case study shows how Rossignol is using XSTRAND™ GF30-PP filament to make functional prototypes for skiing equipment.

“A couple of years ago,” explains Nicolas Puget, Advanced Research Manager at Rossignol, “we started out using ABS filaments like everyone else in the sector: at best it was good for quickly making models, but it was not good for functional prototyping.”

GF30-PP enables Puget and the team to use 3D printing to rapidly make prototypes for a number of new products, including rise plates for skis, slalom tip deflectors and pole grips. In tests, the material proved capable of withstanding real snow conditions in cold chambers, and passing a range of key standardized tensile tests.

In addition, Arnaud Moenne-Loccoz, R&D engineer at Rossignol explains, “It is the first reinforced material that I tried as easy to print as ABS. We just had to adjust the printing bed material.”

Upgrade your 3D printing material

Due the glass fiber content, XSTRAND™ GF-30 PP can gradually wear a standard brass extruder. To optimize the lifetime of these components, Owens Corning recommends 3D printing with a hardened steel extruder. A perforated build plate, HDPE sheet and appropriate adhesive will also ensure optimal performance during build.

XSTRAND™ GF-30 PP is available in both standard diameters for 3D printer feedstock – 1.75 and 2.85 mm, and can be bought on either a 500 g or a 2200 g spool.

Buy XSTRAND™ GF30-PP filament now to take your functional prototyping to the next level.

For more information about the XSTRAND™ materials range you can also contact Owens Corning direct at the following email: [email protected].

Adjudicate the most useful 3D material of the year. Make your nominations for the 3D Printing Industry Awards 2018 now.

For more of the latest product releases and other news, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows XSTRAND™ GF30-PP Filament. Photo via Owens Corning