A team of students and researchers from the University of Oklahoma and Argonne National Laboratory have used 3D printing to produce a low-cost weather station.

The design was based on open-source plans developed by the University Corporation for Atmospheric Research as part of the 3D-Printed Automatic Weather Station (3D-PAWS) Initiative and features over 100 additively manufactured components. Putting the weather station to the test in Oklahoma, the scientists compared its efficacy and durability to that of a commercial-grade station over the course of eight months, with promising results.

Adam Theisen, Atmospheric and Earth Scientist at Argonne and lead author of the study, states: “I didn’t expect that this station would perform nearly as well as it did. Even though components started to degrade, the results show that these kinds of weather stations could be viable for shorter campaigns.”

What are weather stations used for?

Weather stations comprise various instruments and sensors designed to monitor the factors that influence weather forecasts, including temperature, humidity, wind speed, and solar radiation. As well as being a great tool for news channels, weather stations also facilitate research in fields such as agriculture and renewable energy utilization.

Unfortunately, commercial devices can cost several thousand dollars to produce, limiting their accessibility when funding is at a premium. This is where 3D printing comes in, potentially enabling organizations to cut costs down to the sub-$1000 range, all while bringing manufacturing capabilities to remote locations where spare part sourcing may prove difficult.

The 3D printed weather station

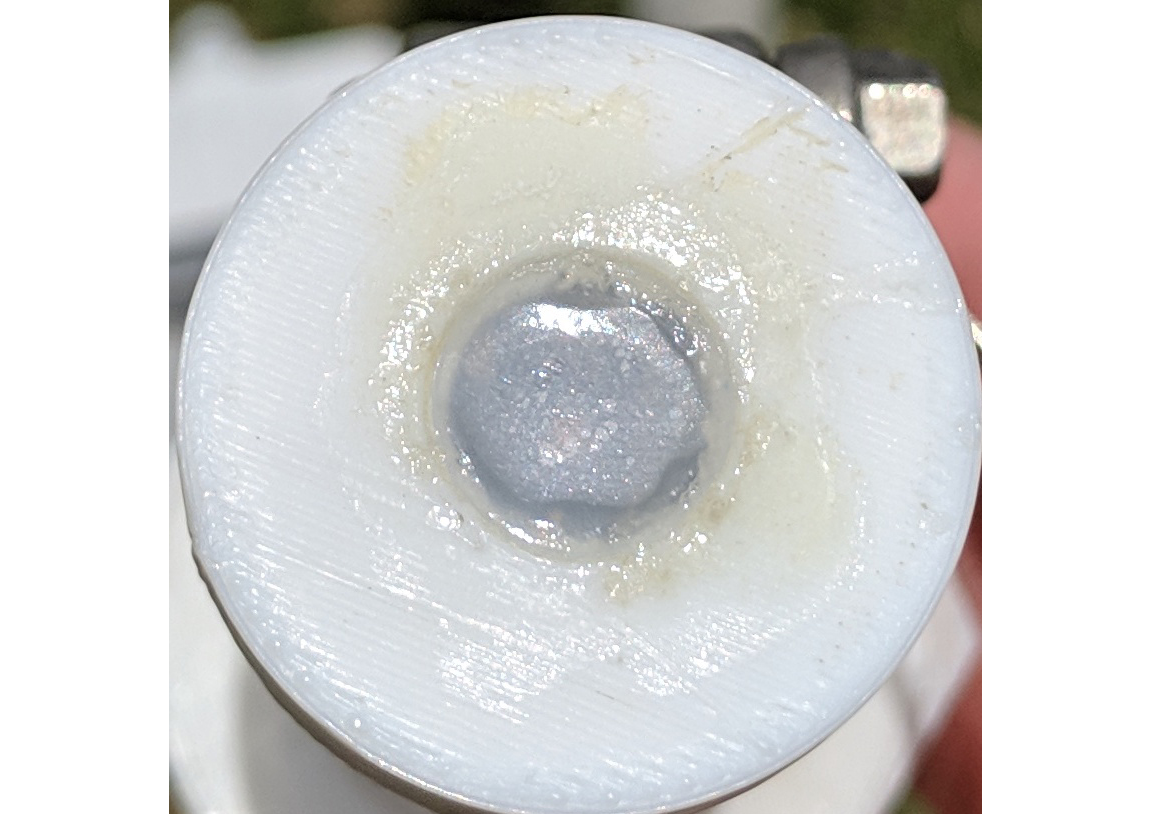

Seeing as the device would be subjected to the harsh environmental conditions of the outside world, the team opted for ASA as the 3D printing material to complement the station’s low-cost sensors. Impressively, the weather station functioned for a full five months before the humidity sensor corroded, and some of the 3D printed parts showed signs of degradation. As a whole, however, the 3D printed frame did hold its own, despite facing rain, snow, and temperatures in the range of -10°C to 40°C.

When it came to performance, the station’s measurements were reportedly comparable to those of a commercial-grade device in the Oklahoma Mesonet, which is a network of environmental monitoring stations. The device’s sensors were perfectly capable of measuring temperatures, precipitation, UV exposure, and humidity accurately. The only instrument that delivered lackluster results was the 3D printed anemometer, which is used to measure wind speeds, as it suffered from low printing quality.

The project ultimately proved that a 3D printed weather station can indeed provide a cost-effective alternative, both in terms of initial start up costs and maintenance costs, to other well-established weather monitoring devices. Theisen concludes: “If you’re talking about replacing two or three of these inexpensive sensors versus maintaining and calibrating a $1,000 sensor every year, it’s a strong cost-benefit to consider.”

Further details of the study can be found in the paper titled ‘More science with less: evaluation of a 3D-printed weather station’. It is co-authored by Adam Theisen et al.

This certainly isn’t the first instance of 3D printing being employed in the development of eco-monitoring devices. Earlier this year, the French National Research Institute for Development developed a water pollution sensor for the wild using Formlabs’ SLA 3D printing technology. The primary objective of this project was to produce a ‘low-cost’ device for environmental monitoring purposes. The team had decided on 3D printing as they wanted to manufacture a user-friendly prototype of the sensor with commercially available tools.

Elsewhere, researchers from the Oak Ridge National Laboratory recently 3D printed a first-of-its-kind smart wall called ‘EMPOWER’, which features weather monitoring capabilities. Built to highlight 3D printing and designed for indoor use, EMPOWER combines concrete additive manufacturing and integrated electronics to serve as a room’s cooling system.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the 3D printed weather station. Photo via Argonne National Lab.