Advancements in filament materials are rapidly moving the 3D printing industry forward, but only if we can keep up.

More makers and companies are using high performance materials such as metallic, glass fiber, and carbon fiber filaments in their specific applications to achieve new levels of performance. One example is 3DXTech, which is pushing the boundaries of engineering grade materials, offering carbon-fiber grades of ABS, Nylon, PETG, and PEEK for industrial and end-use applications. Others, like Markforged, are printing with continuous fibers of carbon, glass, or Kevlar which can be used in demanding applications such as industrial tooling jigs and even steering knuckles. Carbon filament is widely used in fast-growing drone segment and anywhere else that lightweight, high-strength, quick-turn parts are in demand.

Unfortunately, this performance comes at a cost: fast erosion and wear on the nozzle orifice and tip, which leads to changing extrusion diameters and reduces the quality of prints. This also means buying more nozzles and swapping them more frequently, wasting time and money.

The solution seems simple: more durable nozzles. But the marketplace was empty. So Performance 3-d engineered a line of super hard wear-resistant nozzles and challenged Gearswitch to put them through the paces.

3D printing expert Ryan Carag from Gearswitch prints a variety of products, and in particular has printed hundreds of his sleek center console cup holder.

Using high-quality carbon fiber ABS filament, Carag was quick to spot nozzle issues, with some brass nozzles wearing down in as little as 100-200g.

“The CF-R ABS will eat through a normal brass nozzle, as most printers are equipped with, in 250g or less,” he said. “I’ve seen it as bad as 125g before I could put a 0.5mm bit through a 0.4mm nozzle.”

After experiencing extensive nozzle failures (such as the one pictured above), Carag began testing out Performance 3-d Duraplat3-d™ nozzles, machined from A2 tool steel, heat treated to increase hardness and coated for low-friction.

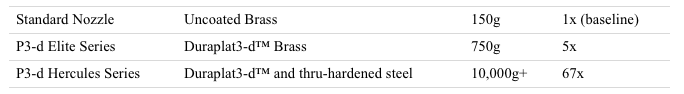

The testing found the P3-d Hercules nozzle to be the most durable, printing over 10,000 grams. This is 67x more wear-resistant than standard brass nozzles.

“Knowing the nozzles would keep on going really removed a lot of the anxiety that’s endemic to manufacturing with a small print farm,” Carag shared.

Carag also found an additional benefit: “The reduced need to level the build plate has opened up the ability to achieve something we’ve been wanting to do with our setup: full automation.”

Durable, reliable nozzles provide the freedom to print with any filament and the knowledge that they will continue to perform, allowing digital manufacturers and enthusiasts to focus on printing innovative products.