3D printer manufacturer Nexa3D has expanded its partnership with BASF Forward AM, the 3D printing arm of chemical company BASF, to produce three new ultrafast photopolymer 3D printing materials for rapid prototyping applications.

The new photopolymers, x45 NATURAL, x45 CLEAR, and x45 BLACK, are engineered to speed up the 3D printing of prototypes across a variety of industries and applications, such as housings, enclosures, pipes, packaging products, and footwear components.

The partnership leverages Forward AM’s expanding portfolio of tailored formulations and Nexa3D’s ultrafast NXE 400 3D printer to improve the speed of turnaround times and offer greater design agility.

“We are excited to expand our partnership with Nexa3D as we believe that our broad range of photopolymers is well-matched for the high throughput of the NXE 400 system,” said Francois Minec, Managing Director of BASF 3D Printing Solutions.

“We look forward to continuing to deliver an expanded portfolio of materials across Nexa3D’s expanding portfolio of photoplastic (SLA) and thermoplastic (QLS) design and manufacturing solutions.”

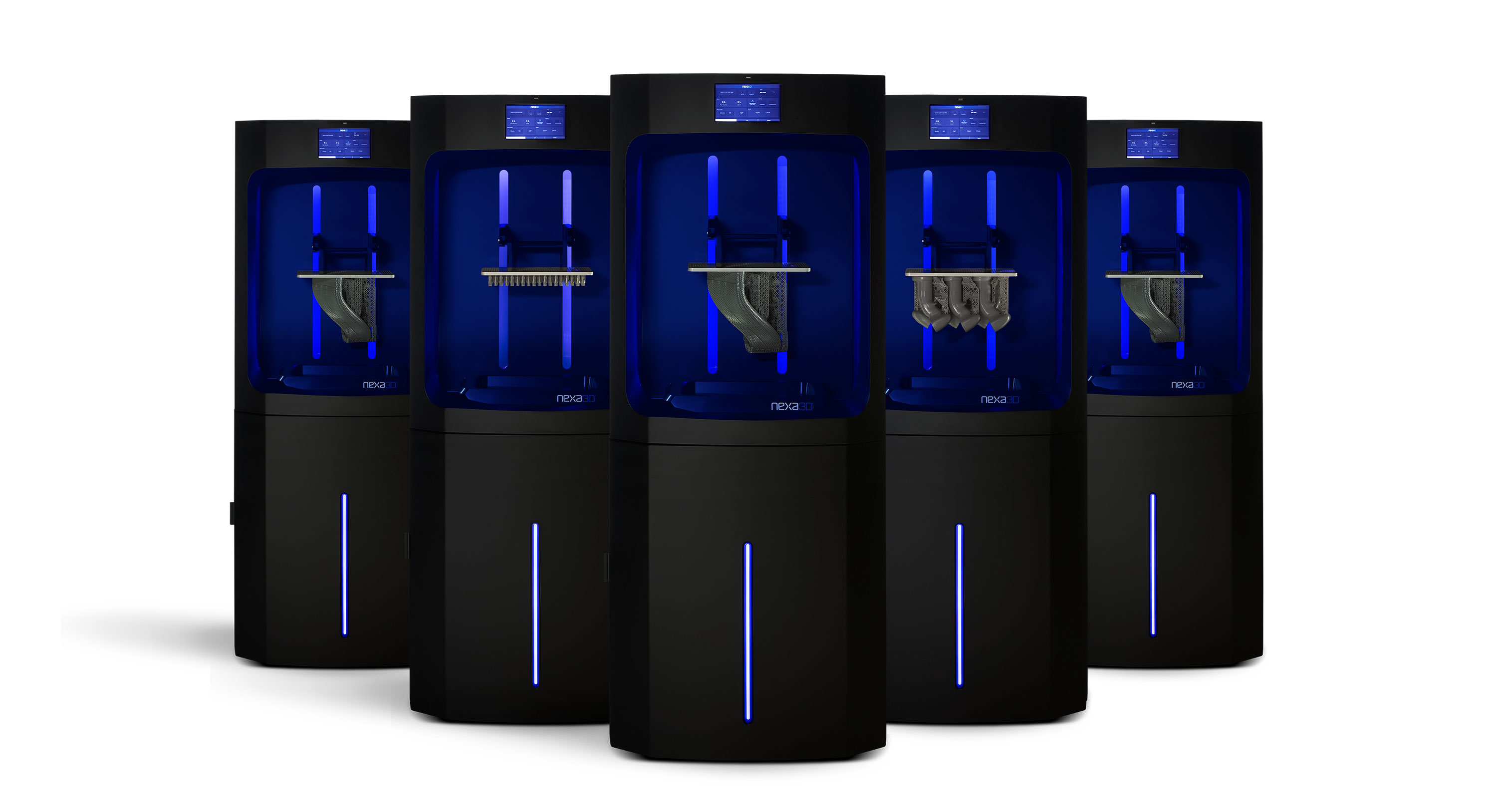

The NXE 400 3D printer

Nexa3D’s flagship system, the NXE 400, is a versatile 16L industrial 3D printer built for a whole host of applications. The machine is equipped with the company’s proprietary Lubricant Sublayer Photo-curing (LSPc) 3D printing technology, Nexa3D’s take on resin-based 3D printing.

With its 275 x 155 x 400mm build volume, the NXE 400 has recently been used to produce custom polymer parts for motorsport applications, as well as for more general manufacturing tooling purposes. According to Nexa3D, the NXE 400 boasts a 20x productivity increase over its industrial competitors.

In addition to expanding its partnership with BASF, Nexa3D has also recently entered into several other alliances with the likes of Royal DSM to fast track the availability of its QLS 350 systems with DSM’s sustainable laser sintering powders for series production, and technology powerhouse Siemens to standardize its entire QLS product line to Siemen’s factory automation and edge computing technologies.

New ultrafast photopolymer materials

The first of the newly launched materials from Nexa3D and Forward AM is x45 NATURAL, a tough material suitable for the 3D printing of models and functional prototypes requiring high-strength and durability.

The material is reportedly capable of much higher print speeds than currently available materials, and ensures first-time build success due to its robust print styles. x45 NATURAL supports a wide range of applications with short processing times, while its draft build mode allows users greater flexibility within their manufacturing processes.

Meanwhile, the second material, x45 CLEAR, is designed for the printing of functional prototypes that need quick turnaround times. Combining clarity and toughness, the material exhibits excellent build speed to give companies greater adaptability within their additive manufacturing processes.

The third photopolymer to be released by Nexa3D and BASF is x45 BLACK, a durable material that features a matte black finish for parts that are usually molded in black plastic, such as automotive parts. X45 BLACK is also hailed as displaying “excellent out-of-printer properties” that ensure both build success and flexibility during the printing process.

The three ultrafast photopolymer materials will be available through Nexa3D’s growing network of resellers.

“Thanks to these new BASF materials and Nexa3D’s open materials platform, fast just got faster,” said Kevin McAlea, COO, Nexa3D. “Both companies are committed to democratizing access to scalable additive polymer solutions for the entire product lifecycle from design to production.

“With NXE 400’s 20x productivity gains and up to 85 percent lower total cost of ownership, manufacturers will benefit from higher productivity, better functionality, and exceptional cost and effectiveness.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a set of NXE400 systems 3D printing wind tunnel parts. Photo via Nexa3D.