A new 3D modelling program from students at MIT consists of a large database of fabricable design templates that will allow a casual user to easily create 3D objects that are ready to fabricate, including any support structures, screws, brackets or braces needed to create stable furniture.

The difference between most real world objects that need to be fabricated and their digital counterparts is, as ever, in the details. 3D models generally lack the details that an object needs to be structurally sound as they are usually just a simplified version of the final product. These missing details include things like brackets, screws, welds and fitting holes. Casual users of design software often find designing fabricable objects extremely difficult if not impossible due to the need for these elements.

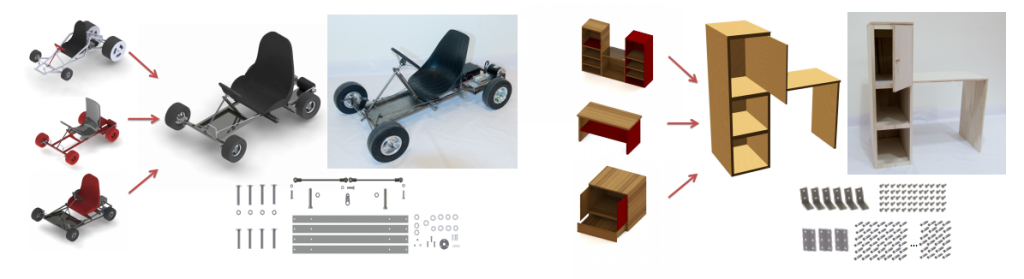

The MIT researchers worked with design experts to create a large database of fabricable models that include all of those missing details, even down to the smallest screw. When designing from scratch, even a simple table could require hundreds of individual parts that traditionally would need to be 3D designed one at a time. This makes the creation of fabricable designs extremely time consuming and usually far outside of a casual designer’s skill set.

Each component in the design database is associated with an individual item in an extensive catalogue of parts. Every design in the catalogue is completely fabricable without any manipulation. But the MIT students took this database and created a program that allows each design to be manipulated. The manipulated designs will scale any required elements needed to maintain the structural integrity of the finished object.

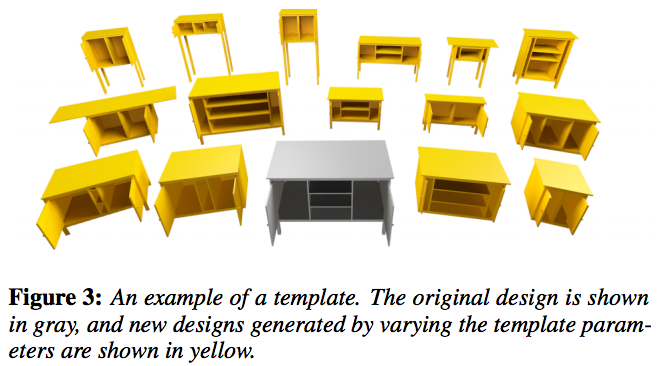

To allow structure-preserving manipulation of the objects, the program automatically converts the designs in the database into hierarchical parameterized templates. This means that the template component takes into account the relationships required to make the object fabricable, such as symmetries and articulation consistencies. As the model is manipulated the structural preserving fittings will automatically scale up or down depending on the design and what material is being used.

For instance, if a wood shelf is being added to a piece of furniture, the program will automatically snap the part into place with the required brackets to hold it to the other parts. If the shelf is glass the brackets will be replaced with the required support structure to hold glass in place. It will even automatically adjust doors to open and close perfectly without having to manipulate them.

So each design in the database can be manipulated into dozens of configurations, creating often unrecognizably different objects that will automatically be stable and structurally sound. The program also contains automatic stability analysis evaluation, so if you try to make an object that will not function correctly it will notify you of the problem. Once your final design is completed the program will produce a list of materials that can be used to construct the finalized design.

Take a look at a video summary of the research:

The researchers used furniture as their example of how the program works, but they also demonstrated how it can work with a go-cart. This program can seemingly be applied to just about anything. It could allow anyone – regardless of their skill level- to design their own computers, cars, clothing, basically anything that has specific and definable rules for structure and construction.

Of course once you have your fabricable design you need to have it created in the real world, and that can often include expensive machining and tooling. That doesn’t change the fact that this program is going to change the way that just about everything is designed, and who is going to be able to design everything. So far this is just research, so don’t expect this to be available in the next update of Photoshop. But I have little doubt that we’ll be seeing remarkable features like these in 3D modelling software in the next few years.

You can read a brief overview of the research here, and you can read the detailed paper cataloguing the research here.