Lately, Milan, my home city, has been fairly active on the AM front. The World Expo that just ended featured several events related to 3D printing, while EMO saw the participation of many AM companies in the huge machine tool industry show, through the work of AITA, the Italian association for additive technologies.

The focus on industrial AM evolution – especially that relating to metal 3D printing – continued through the recent RM Forum, historically one of the leading rapid manufacturing conferences in Italy, which, this year, saw the participation of many of the metal AM industry leaders.

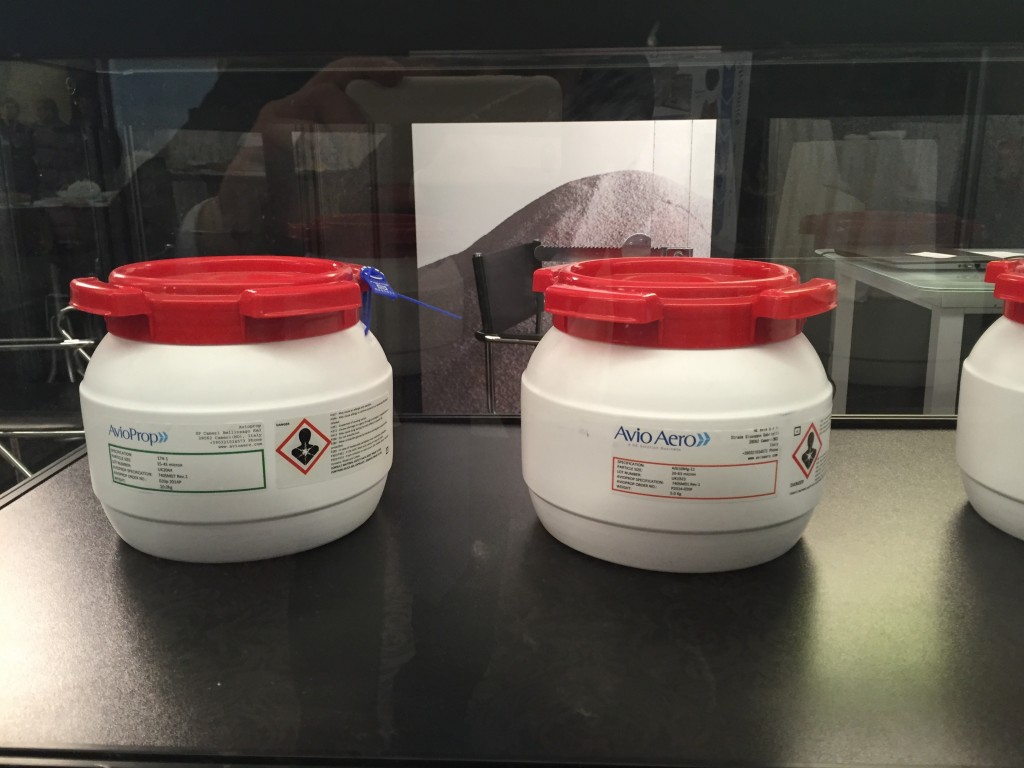

This participation is also fueled by the fact the Italy has already implemented some of the most advanced and unique metal AM production processes and techniques. Take, for example, the case history of Avio Aero (now GE), arguably the world’s most advanced purely AM factory. The company produces several aerospace parts (some of which are already flying on planes), integrating multiple systems, both from EBM (Arcam) and laser based (EOS) manufacturers, as well as an internal plant for atomization of metal powders.

Paolo Gennaro, Additive Manufacturing Product Leader, and Sandro de Poli, president and CEO of GE Italy and Israel, presented the accomplishments achieved and the challenges overcome over the past ten years during the implementation of a fully additive digital factory. De Poli also explained that, given the reduction in fuel consumption, additive factories will be required, in future decades. AM – and its ability to reduce part weight – is not just an option, but in many cases, the only option for aerospace manufacturing.

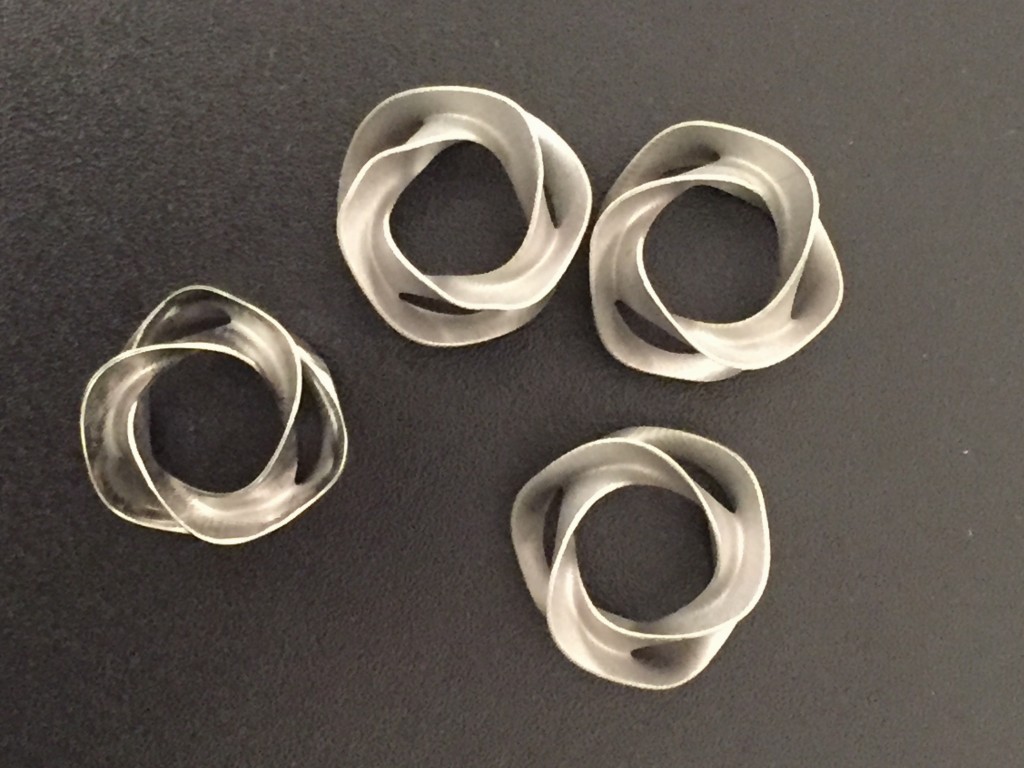

and Dragonfly is that concepts such as “trabecularization” and “topological optimization” are no longer perceived just as abstract ideas, but as very real manufacturing advantages, possible only through AM.

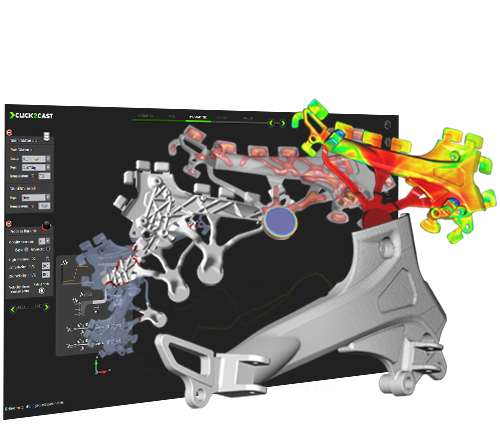

The presentations cumulatively discussed the entire AM process, from CAD design to part-man factoring, with a particular focus on finishing technologies and processes, as well as powder recycling. These aspects in particular were discussed both by Paolo Minetola, technology and production systems researcher at the Polytechnic University of Turin, and Frederic Bajard, who introduced the innovative finishing approach by MMP Technology.

Although many hurdles remain, relating primarily to initial costs of implementing AM, the technology is moving rapidly. Machines are getting faster and larger, new players and technologies are entering the market and, every day, there seems to be fewer doubts that this is the way future manufacturing will be done. Progress may seem slow now, but five years from now, it will probably seems like it went too fast.