Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Israeli food tech company MeaTech has filed a provisional patent application to the United States Patent Office (USPTO) for a novel bioprinting method that it believes has the potential to provide “exceptional control” of multi-layered bioink printing.

MeaTech’s technology reportedly allows for significant control of the droplet size, volume and placement onto a sacrificial substrate layer during in-situ inkjet 3D printing, and could allow for highly advantageous bioprinting resolutions in its meat-emulating products.

The filing of the patent application forms part of MeaTech’s cellular agriculture 3D bioprinting goal of producing premium “cuts” of animal cell-based meat products, and if approved could significantly enhance currently manufacturing processes for cultivated meat.

“This novel technique for achieving more controlled, higher resolution printing may prove to be a promising path forward towards achieving high-throughput, large-scale cultivated meat production,” said Sharon Fima, MeaTech CEO. “As a 20-year veteran of the printing industry, I recognize the significant potential this patent application holds, as it directly addresses key challenges currently facing the bioprinting industry.”

3D printing cultured meat

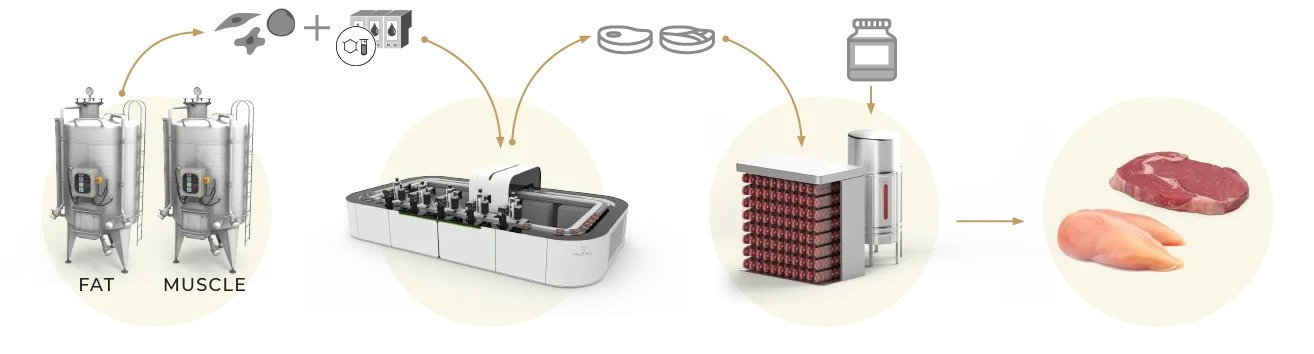

MeaTech’s ambition is to develop commercial and sustainable technologies to produce lab-based alternative meat proteins that eliminate the need for animal slaughter. The company is currently developing a novel proprietary bioprinter to deposit layers of cells, scaffolding, and cell nutrients to form 3D printed cultured meat.

The technology behind the bioprinter was successfully tested in November last year, when the company produced an edible cultured beef fat structure. In the same month, MetTeach closed a $7 million funding round to ramp up the development of its 3D bioprinted cultured meat production technologies, shortly after filing for an IPO in the US.

The company has also completed the acquisition of cultured fat product developer Peace of Meat for £17.5 million, and will leverage the firm’s technologies to expand its cell-based offerings and accelerate its cultured fat development, in turn shortening the time to market for the products.

Earlier this year, MeaTech announced a number of key milestones for its business, including that it had become the first publicly traded company in the US to focus on cultured meat in a move that raised $28 million for the firm.

MeaTech’s bioprinting patent application

MeaTech’s novel bioprinting method reportedly provides exceptional printing control during its multi-layered bioprinting process. The technology provides the operator with significant control during in-situ inkjet printing, enabling them to precisely control the size, volume, and placement of droplets onto a sacrificial substrate layer.

According to MeaTech, this level of control allows for “highly advantageous” bioprinting resolutions that allow the company to produce its thick, meat-emulating products. The patent-pending method could also yield important bioprinting flexibilities, such as increased printing speeds and the capability to use a range of inks with greater viscosity, which have traditionally been difficult to bioprint.

If approved, MeaTech believes the patent could “significantly enhance” manufacturing processes for cultivated meat.

So far, the company has filed six provisional and non-provisional patent applications with the USPTO and Word Intellectual Property Organization (WIPO). The patents cover MeaTech’s 3D printing activities, products, and much of its supply chain, including post-processing.

The Israeli start-up scene is continuing to take strides in advancing the 3D printed food sector, with several food technology companies experimenting with and embracing the technology for alternative meat products.

At the tailend of 2020, food tech firm SavorEat raised $13 million in its Initial Public Offering (IPO) on the Tel Aviv Stock Exchange, which valued the company at $51.2 million. The firm’s “robotic chef” uses 3D printing to transform a plant-based formula into cooked products that emulate meat.

In February, food 3D printing firm Redefine Meat raised $29 million in Series A funding to support its commercial launch later this year, and announced plans to become the “world’s biggest alternative meat company” by 2030. The company unveiled its first 3D printed vegan steak product in July last year, and is continuing to develop its alt-meat portfolio.

Also active in this sector is cell-based 3D bioprinting platform Aleph Farms, which grows “real steak” directly from cow cells, and has previously 3D printed meat on the International Space Station (ISS).

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

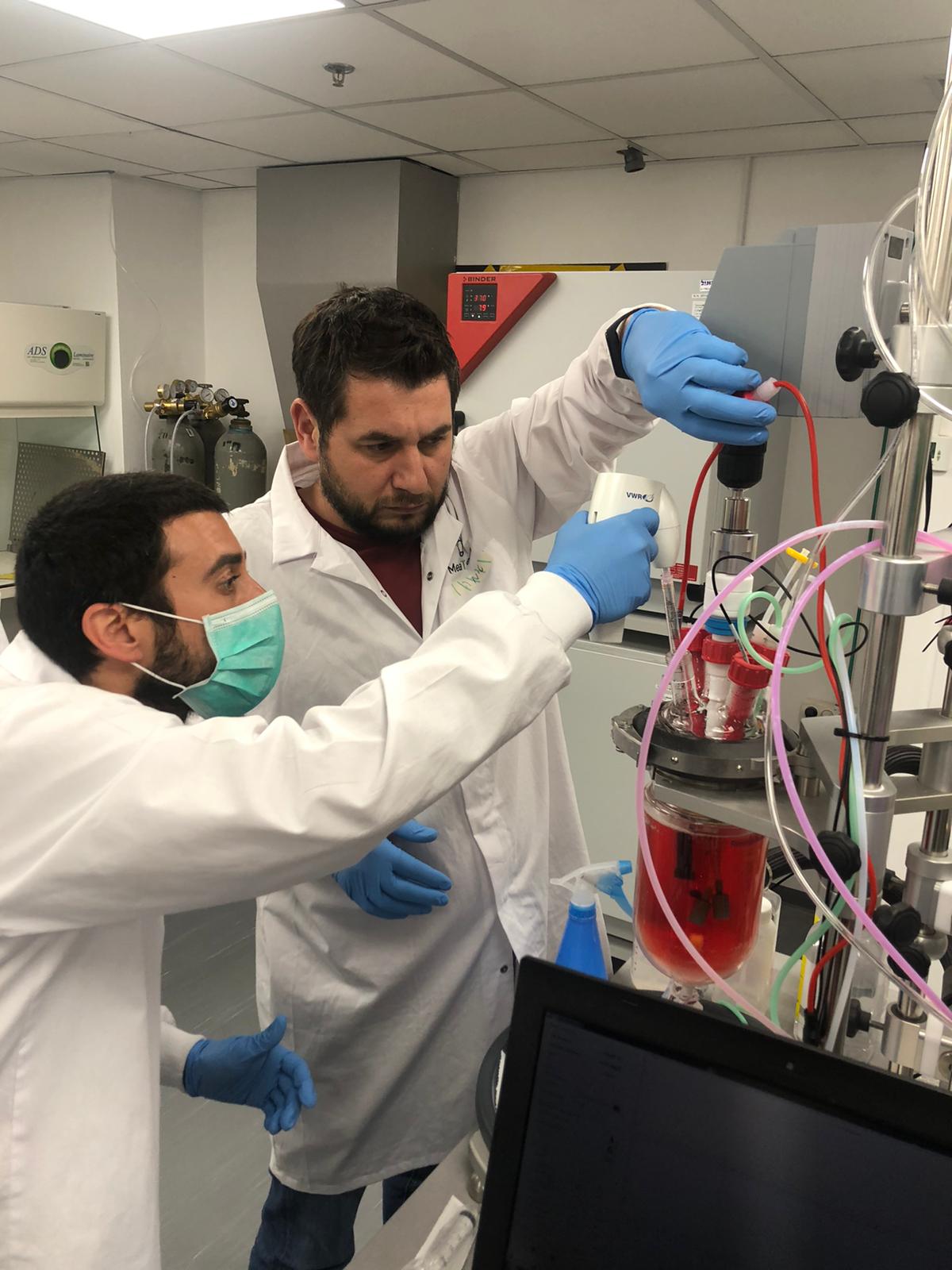

Featured image shows MeaTech 3D bioprinting a slab of real meat. Photo via MeaTech.