Marine Corps Systems Command, the acquisition command of the United States Marine Corps, is now responsible for training US Marines to use 3D printing, equipping them with the skills to quickly fix equipment malfunctions on the battlefield.

The changeover occurred in the first quarter of 2019 and saw MCSC take over from Next Generation Logistics, an innovation branch of the Deputy Commandant Installation and Logistics (DC I&L). The decision has also led to the creation of MCSC’s Advanced Manufacturing Operations Cell (AMOC), established to advance AM throughout the Marine Corp.

“The innovation training allows Marines to use tools, such as 3D printing, to fix their own problems,” said Capt. Matthew Audette, AMOC project officer at MCSC.

“We are democratizing the ability to design solutions.”

Integrating 3D printing into the Marine Corps

For several years the Marine Corps has used 3D printing as a cost and time efficient method to manufacture spare parts for new and legacy machinery.

For example, a team of U.S. Marines have previously printed a part for the door of a F-35 stealth fighter, in total saving $70,000 in costs for an entirely new door. In another instance, the Combat Logistic Battalion 31 (CLB) fabricated a new bumper for an F-35B fighter landing gear door, also saving time and costs to replace the entire door assembly. Other examples include a biodegradable 3D printed aerial drone delivery system and a 3D printed concrete barracks.

“Advanced manufacturing puts manufacturing at the point of need. The Corps views that as a significant advantage,” said Master Sgt. Douglas McCue, additive manufacturing lead at Headquarters Marine Corps. “The entire Marine Corps saw value in additive manufacturing.”

Encouraging initiative with 3D printing

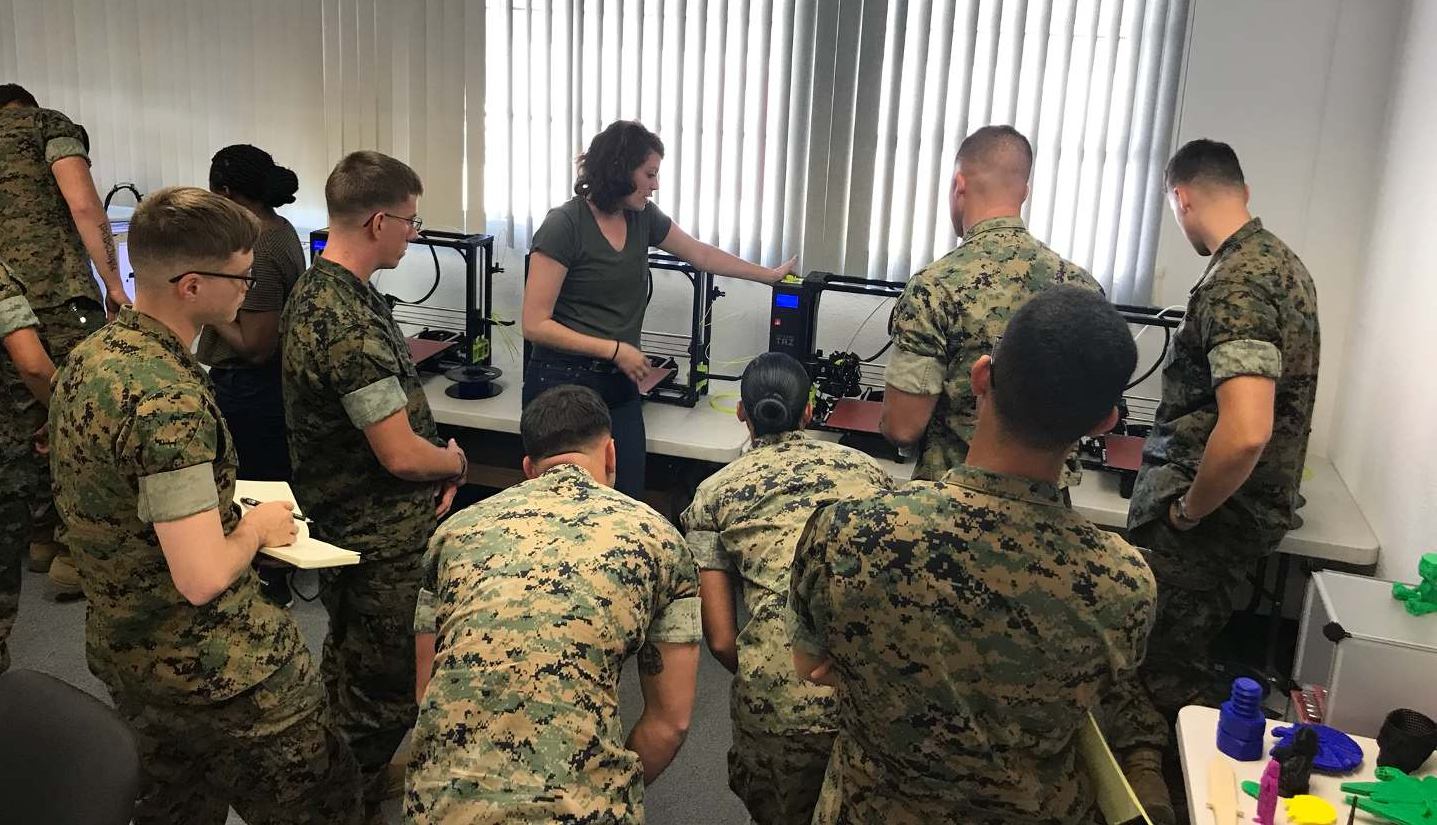

Starting earlier this year the MCSC began to provide instructional courses on basic computer-aided design, 3D printing and other technical skills to Marines, allowing them to produce custom parts on-demand.

One example of where this has already worked successfully is the Corps winter snow shoes. The Corps has begun training in winter weather in recent years, creating a need for snow shoes, however the clip that attaches to these shoes can easily break, causing Marines to go back to regular, unprotected shoes.

A group of Marines brainstormed ideas to solve this issue, and ultimately decided to 3D print replacement clips. The group contacted AMOC, and the department taught them to 3D print clips to attach to their snow shoes.

“The Marines themselves came up with the idea for a 3D-printed snow shoe clip, and it’s been helpful for them,” said McCue.

MCSC training will primarily take place within a Marine Maker lab in Alexandria, Virginia, but may occasionally take place at Marine Corps bases in North Carolina and California, and some overseas locations.

Subscribe to the 3D Printing Industry newsletter and follow us on Facebook and Twitter for the latest news in additive manufacturing.

Visit our 3D Printing Jobs board to find new opportunities in the 3D printing industry.

Featured image shows Staff Sgt. Paul McCollough, Unmanned Aerial Vehicle Operator, using an industrial machine to produce 3D-printed objects aboard Marine Corps Base Quantico, Virginia. Photo via U.S. Marine Corps.