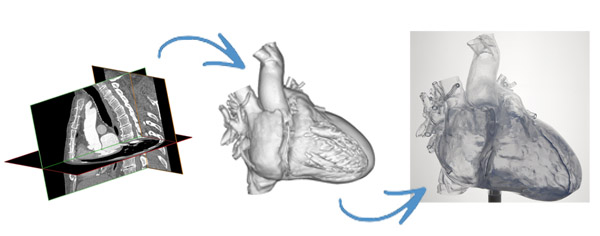

Additive Manufacturing and 3D printing pioneer Materialise has launched a new 3D printing service for patient-specific cardiovascular models from medical image data called HeartPrint.

The proposition behind this launch is that quality 3D printed models of patient-specific cardiovascular anatomy are useful — and valuable — assets to researchers, interventionists, educators, marketing professionals and sales team’s alike. Materialise, via its HeartPrint service, plans to offer a continuously expanding library of ‘off-the-shelf’ 3D printed anatomical models as well as a service for patient-specific models printed from DICOM images (CT or MRI). Thanks to 3D Printing technology, these models are able to combine a range of rigid and flexible materials of varying transparencies in a single print, replicating more than just the shape of a patient’s anatomy.

HeartPrint models are ideal for device R&D (deployment studies and flow tests) and First in Man or (pre-)clinical trials (intervention preparation and training). As medical device companies are striving to get to market faster and provide solutions for as many patients as possible, the relevance of patient-data based benchtop models is clear.

Peter Verschueren, Cardiovascular Team Leader at Materialise commented: “At Materialise, we are proud to offer these accurate anatomical models. Our proprietary multi-material processes allow us to 3D print both diseased (e.g. calcified) or healthy anatomy. I am excited about the enthusiastic response from the market and looking forward to future advancements we have in the pipeline.”

I wanted to know more about these “proprietary multi-material processes” because to date, I only know of one company that can do it. And it isn’t Materialise. However, in the tradition of the self-effacing Materialise, this information slips out quietly having been used in house very effectively. I asked for more information about the multi-material process and the proprietary nature of it.

Beyond this, the HeartPrint service will supply highly accurate benchtop models that can be designed specifically to reflect a range of patient scans from a certain demographic or pathology and used to test device deployment, perform flow studies and analyze deformations in the patient’s anatomy to support their recovery and care.

In addition, for medical device companies cardiovascular models are ideal for marketing and promotional efforts so that devices can be shown deployed in demo models labelled with your company logo! They have also proven to be an excellent tool for anatomy education, physician training and communicating with a team.

“For decades, Materialise has been leading the way in the medical data and 3D Printing sector. We believe that this service is a natural extension of our core competence at Materialise,” concluded Koen Engelborghs, Director, Biomedical Engineering. To find out more about HeartPrint you can visit the source link.

Source: Materialise

About Materialise

For nearly twenty-five years, Materialise has been leading the way in the field of Rapid Prototyping and Additive Manufacturing (AM). With a machine park of nearly 100 machines, Materialise is proud to be the largest Service Bureau under one roof in the world! We take pride in helping to advance the Additive Manufacturing industry by developing software, machines and materials that make AM more and more competitive as a viable means of manufacturing. The technology is ideal for enhancing our medical offerings and allows us to lead the way in 3D Printing everything from anatomical models to surgical guides.