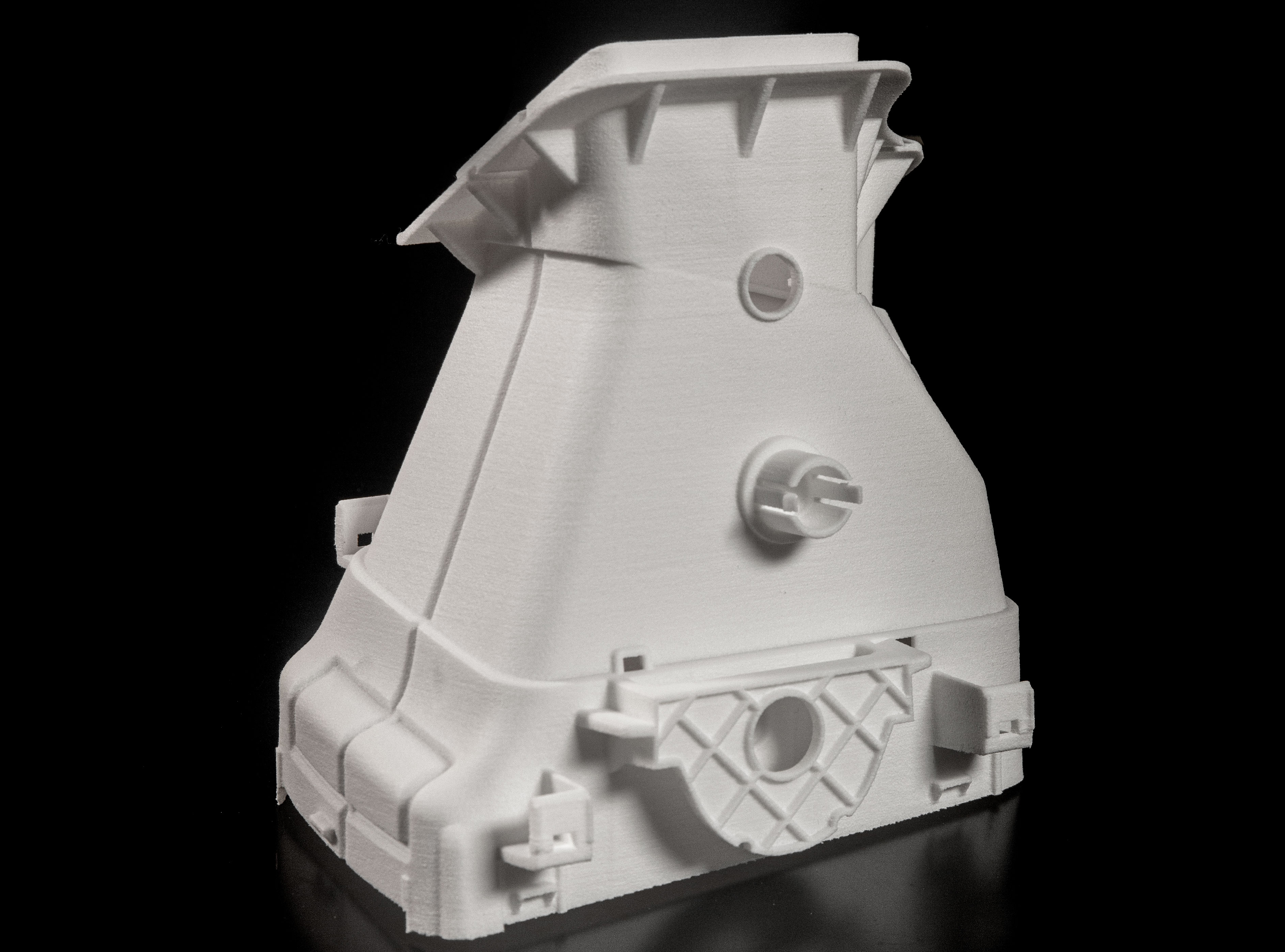

Belgian software and 3D printing service provider Materialise has announced the launch of Bluesint PA12, a technology designed to significantly increase the resource efficiency of the laser sintering 3D printing process. The manufacturing breakthrough allows printing with up to 100% re-used powder and is an important step for the firm in aiding its customers to make sustainable choices.

Bluesint technology seeks to reduce the “orange-peel” effect that can be observed when re-using powder. This effect causes an uneven surface and diminished part-strength, it is caused by the cooling of layers. To overcome this Bluesint makes use of two lasers, one to sinter a new layer, while the other maintains a temperature that keeps the previous layer at the correct temperature.

During a press conference today the company confirmed that the technology was developed in-house without working with a specific vendor – a spokesperson did not rule out development of a similar technology that would be applicable to metal powder in the future.

Bluesint PA12 was one of several announcements made by Materialise. The company also revealed its Process Tuner, an online platform designed to achieve mass-manufacturing of 3D printed parts, its Magic Storefront, a cloud-based CRM software enabling 3D printing factories to close their process loops, and the 25th edition of Magics.

“The global pandemic creates human suffering and comes with a tremendous economic cost. But in the destruction, we can already find the seeds of renewal,” said Fried Vancraen, founder and CEO of Materialise. “At the start of the 4th decade of 3D printing, we are entering a decade of potentially radical innovation and creativity that will replace old and obsolete processes with solutions that better respond to a new reality.

“I believe this new reality will be more digital, more personalized, and more sustainable.”

Improving sustainability with Bluesint PA12

Up to half of the powder used within laser sintering processes can become waste, and recycling of this used powder is often limited and subsequently unsuitable for re-use in other 3D printed parts.

According to Materialise, the resulting parts have similar mechanical and visual properties to other powders used in laser sintering, meaning that users can choose Bluesint PA12 not only for its environmental credentials but for its technical specifications, too.

“With Bluesint PA12 we are able to significantly reduce powder waste,” said Jurgen Laudus, VP and general manager of Materialise Manufacturing. “Bluesint PA12 represents a major step towards making 3D printing more sustainable and is an example of how we empower our customers to make a choice for sustainability.”

The company intends to have several laser sintering machines running with Bluesint PA12 over the course of 2021, and is aiming to re-use more than five tons of powder that would usually be wasted during the start-up phase of the initiative. Selected customers will also be invited to participate in a beta program for the market validation process of the new technology.

Scaling production with Materialise’s Process Tuner

Included in the series of announcements is the Materialise Process Tuner, an intuitive online platform engineered to speed up the process tuning required for mass-manufacturing 3D printed parts. The platform will aid manufacturers, service bureaus, and machine builders in scaling up their operations while reducing the costs and waste associated with printing multiple test samples to discover their desired process parameters.

Usually, validating the printing process for a single part can require up to a thousand test samples reliant on trial and error, which is often time-consuming and expensive. According to Materialise, its Process Tuner significantly reduces the number of physical test prints needed in order to discover the optimal print settings for a part through a combination of advanced automation, Artificial Intelligence (AI), and smart simulations to predict sub-optimal prints.

The Process Tuner is the company’s first cloud-native Magics application and can be accessed through either a web browser, an API, or deployed and run on-site. Firms preparing for serial additive manufacturing and who are seeking to speed up their process tuning can enter the platform’s early adopter program. The Materialise Process Tuner is predicted to be available in the first half of 2021.

“When we ask companies what the main obstacles are for scaling up their production, they tell us it’s too expensive, too complex, and too time-consuming. As a result, some companies think twice before scaling up,” said Stefaan Motte, VP and general manager of Materialise Software. “With the Materialise Process Tuner, we allow them to find the optimal print settings without wasting machine and engineering time.

“In our own 3D printing factories we were able to reduce the cost per optimized parameter set by 50%, which is impressive.”

Closing the loop with Magics Storefront

Materialise’s new cloud-based CRM software automates the intake and sales process of 3D printing factories in order to improve communication with their customers. Both internal and external service bureaus are to benefit from the software, according to Materialise, providing they want to automate the intake processes for incoming print orders in an online environment.

To this end, Storefront can be used as a standalone solution to provide automatic and manual price calculation and quoting, alongside additive manufacturing data preparation, order management, and incorporating payment and shipment providers. The software can also be integrated with Materialise’s Streamics and Magics software to give greater flexibility to firms operating with multiple print technologies and complicated environments.

A pilot program with beta customers is currently underway, and Materialise expects to roll-out Magics Storefront in the second quarter of 2021.

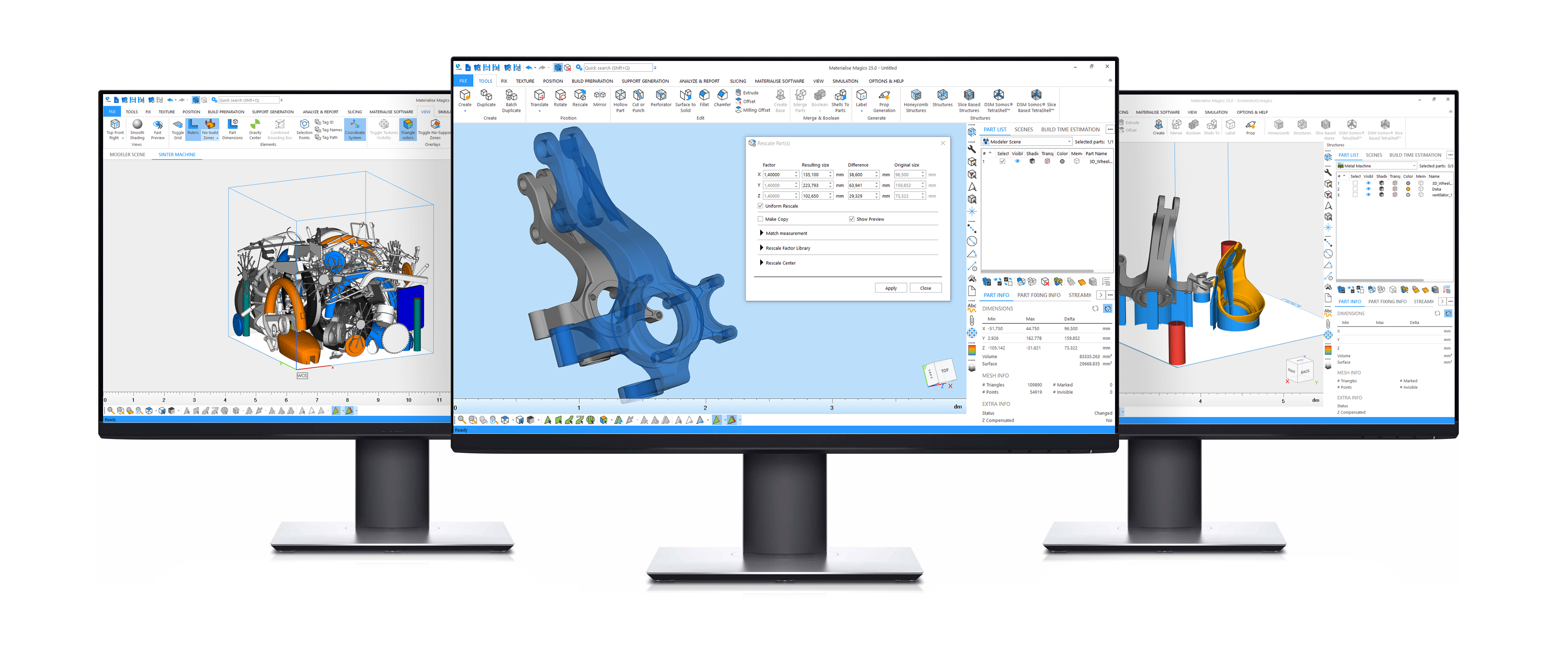

Introducing Magics 25

Last but not least, Materialise announced the 25th edition of its flagship software suite for data and build preparation, Magics. In the latest update, the Fix Wizard feature has been integrated into the tool pages, enabling users to see and fix any errors more quickly and easily.

Users can also take advantage of the Full Build Simulation for metal printing tool, part of the Simulation module within the software. Multiple parts can be simulated at once in order to speed up the simulation process and predict what effects the parts could have on each other. The base plate can now also be simulated with the parts to highlight any potential deformation which could affect the build.

Materialise is holding five in-depth sessions as part of its Think-In webinar series, within which the announcements above will be discussed in more detail.

Are you announcing new products or developments at Formnext Connect? Get in touch to share your news.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Be sure to subscribe to the Another Dimension podcast on your chosen podcast player to make sure you never miss an episode.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a part 3D printed with Bluesint PA12 technology. Image via Materialise.