Mass Portal, a Latvia-based 3D printer manufacturer, has named Imants Treidis as its new CEO following the departure of co-founder Janis Grinhofs.

As of this month, Grinhofs, has founded and will lead FabControl, an independent software platform for managing additive manufacturing machinery and workflow.

“We will continue to serve our existing customers and industrial partners, in the same time striving for excellence in supplying the industry with highest quality machines and tailor built solutions for additive manufacturing needs,” said Treidis.

Shifting towards Industry 4.0

Founded in 2012, Mass Portal has developed a range of thermoplastic extrusion 3D printers, including its first delta style 3D printer, filament dryers, and an automated 3D print farm system, Dynasty AMS.

With an open material approach, the Dynasty AMS was created as an adaptable solution for low volume production. It automatically mounts print beds, calibrates 3D printing units, starts and stores print jobs, resulting in limited assistance from an operator.

With this system in mind, Grinhofs, who served as Mass Portal’s CEO since 2014, now plans to build a next-generation software platform to better manage digital manufacturing workflows.

Through Grinhofs’ vision, the establishment of the FabControl software platform will prepare and run print jobs as well as manage the entire workflow process within a variety of print farm systems. The FabControl platform will not be exclusive to Mass Portal.

“We are looking forward to an open, Industry 4.0 world, where automated, approachable and smart workflows integrate hardware, materials and software from multiple vendors,” added Grinhofs, the new Founder and CEO of FabControl.

The term Industry 4.0 is still controversial, and is an area where real-world experience does not not always tally with executive vision. A recent survey conducted by The Engineer found the majority of respondents felt the buzzword was unhelpful. Let us know your thoughts.

Automated 3D printing systems

Time and efficiency are important factors for companies manufacturing functional products and prototypes. Thus, automated 3D printing systems, which remove various stages of the 3D printing process are significantly useful. The reality of how close 3D printing is to becoming a fully industrialized technology is a topic explored by our series looking at trends in additive manufacturing for end use production.

Last year, along with other large-format 3D printing systems, Mass Portal demonstrated the automated capabilities of its Dynasty AMS system at Rapid + TCT.

Following this, Sandia National Laboratories developed an automated 3D printed part testing robot, to speed up the part qualification process, an important barrier to the adoption of additive manufacturing.

With the advancements of automated 3D printing systems and software, users may have a less challenging experience with additive manufacturing.

Stay updated with the latest 3D printing news by subscribing to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Looking for a change of pace? Seeking new talent for your business? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

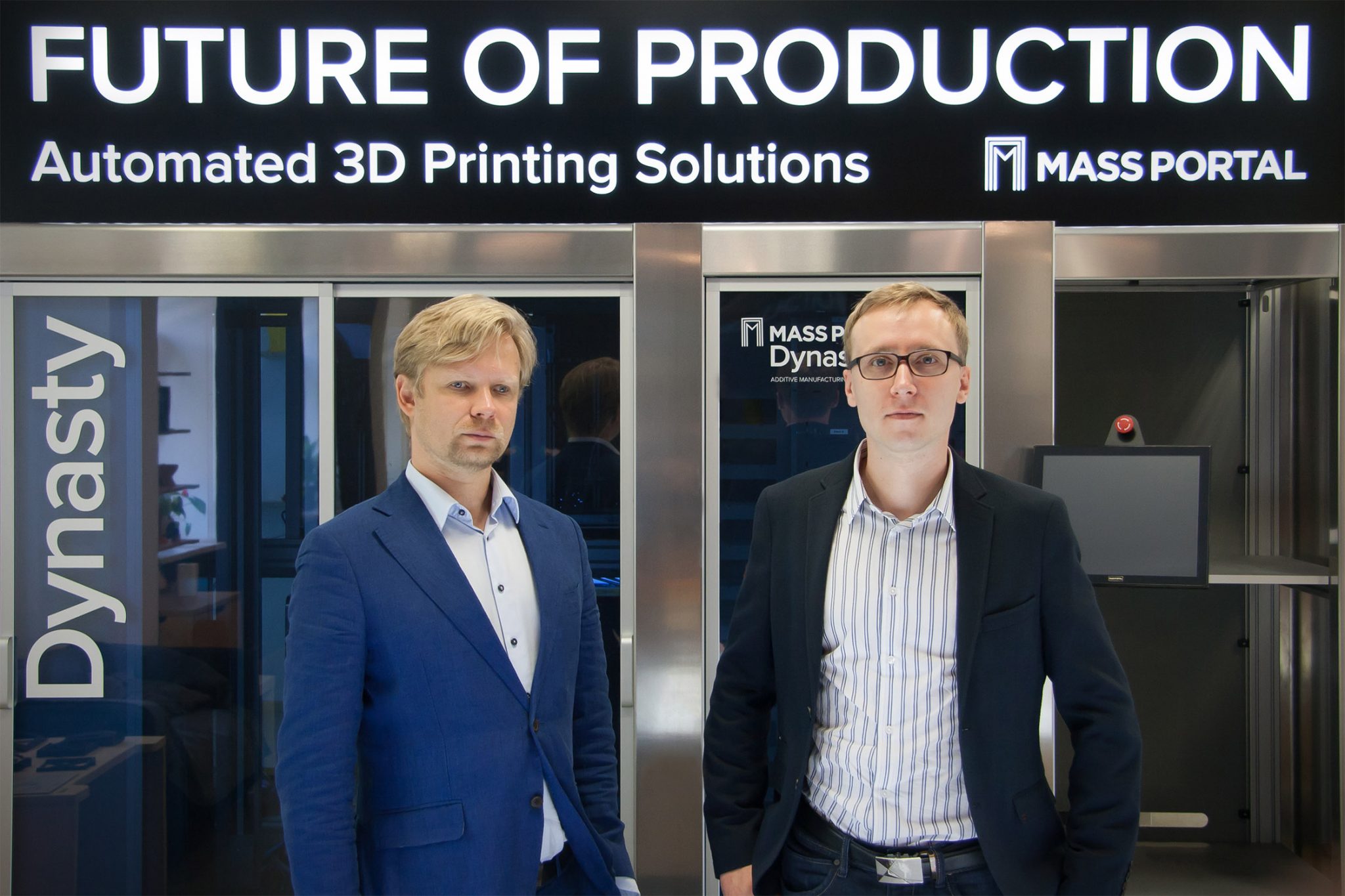

Featured image shows Mass Portal’s former co-founder, Janis Grinhofs (left) with new Mass Portal CEO, Imants Treidis. Photo via Mass Portal.