The 2021 3D Printing Industry Awards shortlists are open for voting, have your say now.

Sardinian architecture and design firm MASK Architects has designed what it claims is the world’s first steel 3D printed collection of modular houses in the city of Orani, Sardinia.

Named “Madre Natura” or “Mother Nature”, the project will be constructed using a novel steel 3D printed ‘exoskeleton’ construction system called EXOSTEEL, which leverages technology from Dutch 3D printing technology provider MX3D and a robotic arm from automation corporation KUKA.

With the first design step of the project complete, MASK Architects is searching for an investor to bring the project to fruition and a mutual agreement is in the works with MX3D for the companies’ joint participation in the build.

The “Madre Natura” concept

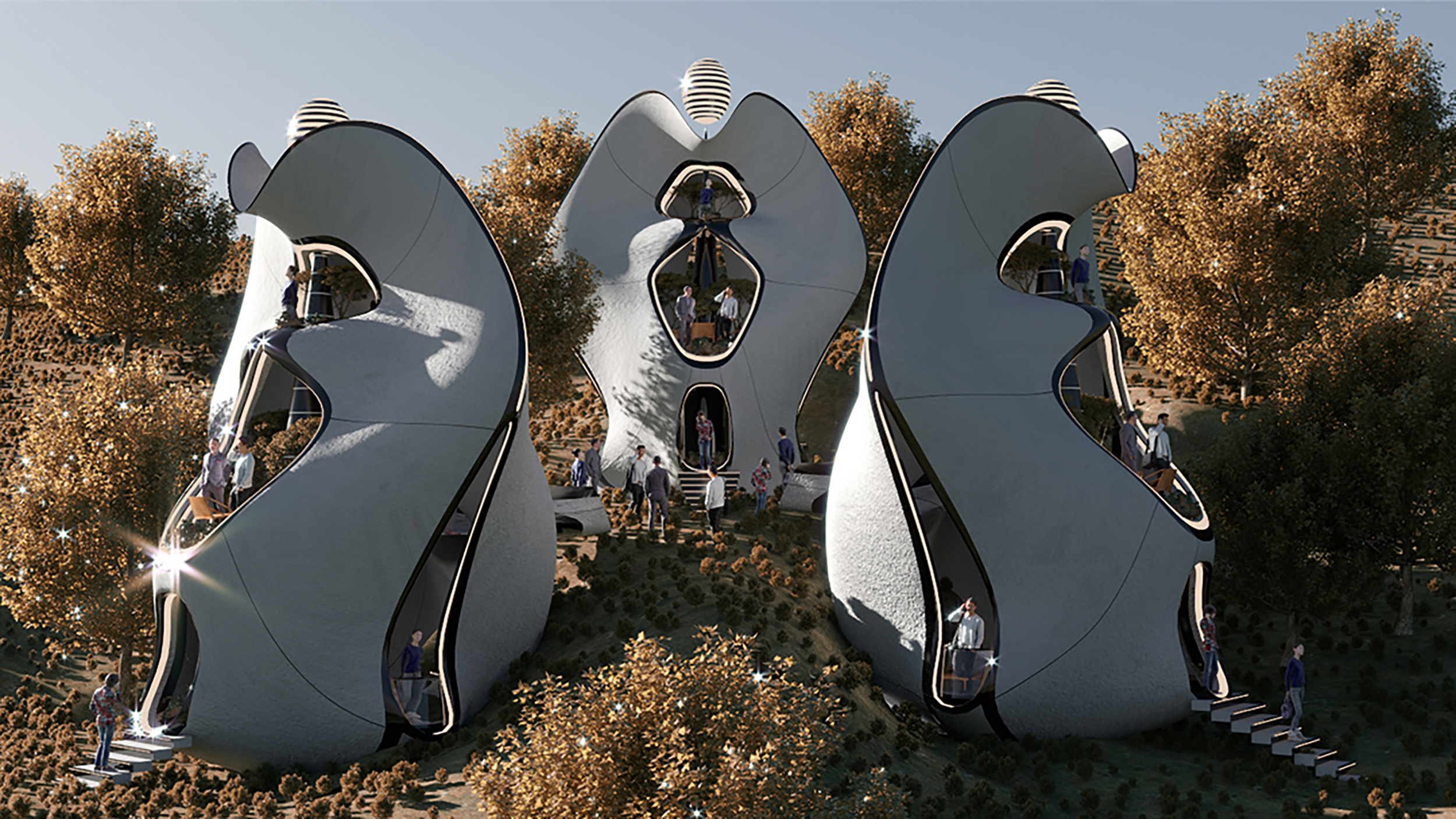

MASK Architects drew inspiration from Italian sculptor Costantino Nivola and his famous “La Madre” sculpture for the design of their Madre Natura habitat. The project will see the sustainable construction of a modular-style housing development set within Orani’s sloping mountainside.

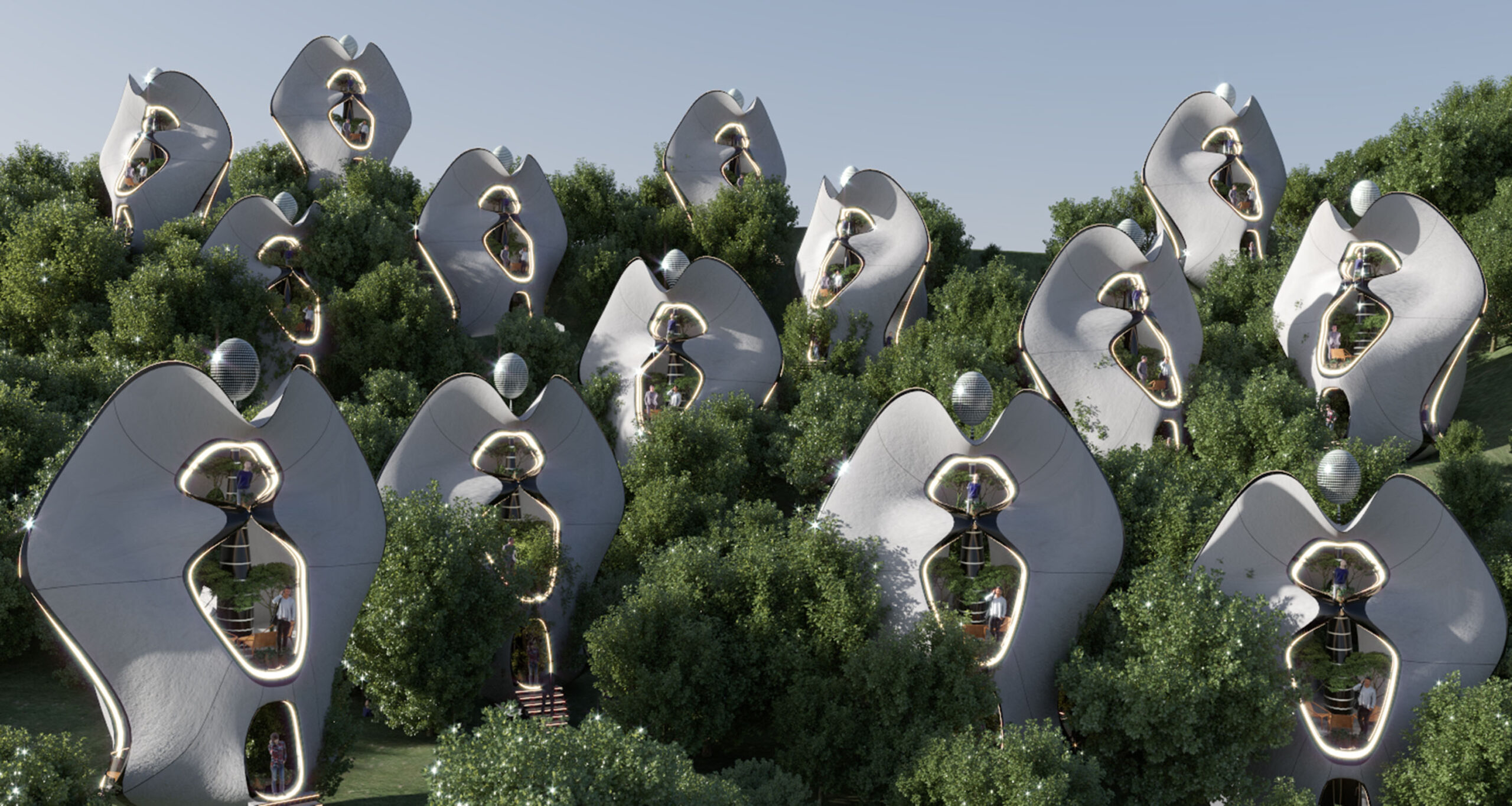

Madre Natura will be situated near the Nivola Museum, and will become a “living landmark” integrated harmoniously with its surroundings. The design studio envisages the cluster of homes to function as a housing development for the local community, eventually forming a small village.

The development will consist of multiple heart-shaped white houses with central “energy towers” that mimic the head of Nivola’s La Madre sculpture. Each building will be designed to be entirely self-sustaining and capable of withstanding Sardinia’s natural climate and weather conditions. The houses will be constructed with built-in voids that guide Sardinia’s high winds through each building towards the development’s communal wind turbine, which will deliver power to the homes.

Each home will also feature individual energy conduits covered in solar panels that will harvest solar energy to generate power for the homes. The main centered energy tower that houses all the systems will be constructed using the EXOSTEEL steel robotic 3D printing technology.

The EXOSTEEL exoskeleton

Once the project moves from design concept to physical construction, MASK Architects plans to build the homes by inserting a hollow central column one third of the building’s height into the ground, which will be reinforced by wooden beams that support the home’s three floors. Each floor will be divided and supported by facades made up of panels that mimic the organic shape of the house.

Each home will be fabricated using the EXOSTEEL steel 3D printing exoskeleton construction system, which leverages MX3D’s 3D printing technology and KUKA’s robotic arm.

MX3D’s proprietary Wire Arc Additive Manufacturing (WAAM) technology is designed to integrate with industrial robots and power sources to transform them into 3D printers utilizing the directed energy deposition (DED) 3D printing process.

The company has previously demonstrated the capabilities of its WAAM technology through the 3D printing of a stainless steel bridge in the heart of Amsterdam. The ‘MX3D Bridge’ had been in the pipeline since 2015 before it was unveiled earlier this year, and involved the use of four industrial WAAM robots working in unison to 3D print over 6,000kg of stainless steel.

For the Madre Natura project, MASK Architects is hoping to leverage MX3D’s WAAM technology to 3D print “all the structural parts, columns, load-bearing beams, and supporting elements” of the houses. The plan is to 3D print steel powder using WAAM integrated with a KUKA robot arm with a laser tool to construct the different aspects of the buildings.

MASK Architects is currently searching for an investor to take the project to the next stage, and the technology and design still needs some refining before Madre Natura can become a reality.

The design studio told 3D Printing Industry: “This is only a first step, we know that we have found a solution but we need to improve it. We are designing bold, organic houses to catch the eye of all the people in this field, but next projects should be more sleek and sharp.”

Ultimately, this seems to be a ‘watch this space’ kind of project, with various factors to iron out before these futuristic eco-houses begin to populate Sardinia’s mountainsides. The first being the finalization of the mutual agreement with MX3D for their role in the project. If successful, Madre Natura could provide an impressive benchmark for WAAM’s potential capabilities in the construction sector.

3D printed housing projects

As the scalability of construction 3D printing continues to improve, the technology is being increasingly leveraged for the building of commercial homes and neighborhoods. Examples include ICON’s 3D printed housing community for low-income families in Mexico, and PERI Group’s additively manufactured three-storey apartment building in Wallenhausen.

Meanwhile in March, Californian start-up Mighty Buildings announced plans to 3D print 15 eco-friendly homes at a commercial five-acre site near Coachella Valley.

Elsewhere, more novel approaches to construction 3D printing have been explored, such as WASP’s sustainable 3D printed habitats, TECLA, GAIA, and “The House of Dust”. The structures were built using the firm’s Crane WASP 3D printer using entirely recyclable materials, in line with WASP’s mission to develop digital fabrication processes that advance the principles of the circular economy.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows render of the 3D printed houses within the Madre Natura development. Image via MASK Architects.