Markforged, a manufacturer of industrial-grade FDM systems, has announced the launch of its new FX20 3D printer and ULTEMTM 9085 filament.

The large-format composite 3D printer is primarily designed for high-strength end-use parts in industries such as aerospace, defense, automotive, and energy. Coupled with the new flame-retardant ULTEMTM 9085 offering, the FX20 can be utilized for heat-resistant applications via Markforged’s proprietary Continuous Fiber Reinforcement printing technology.

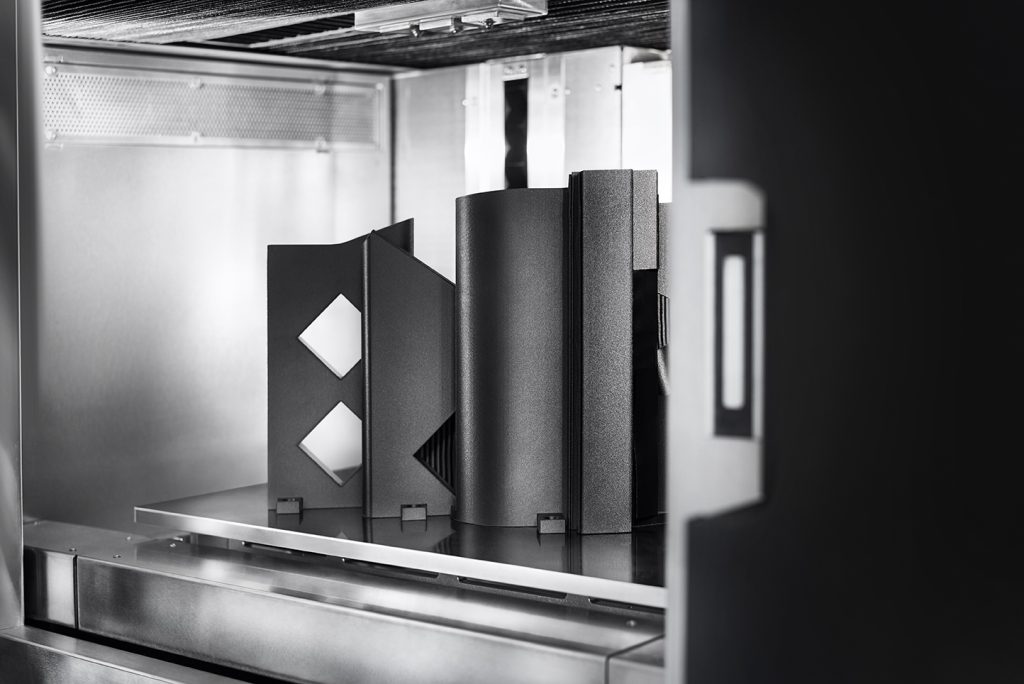

Additionally, the FX20 is also Markforged’s largest 3D printer to date, sporting a build volume measuring 525 x 400 x 400mm.

Shai Terem, President and CEO of Markforged, said, “Markforged continues to build on our innovative legacy and lead the way in composite 3D printing—the future of manufacturing. With the releases of the FX20 and Continuous Fiber Reinforced ULTEMTM 9085 filament, we’re now fulfilling that promise to manufacturers who previously, in the most demanding environments, were unable to experience the benefits of the Digital Forge and our unique materials.”

Metal and composite 3D printing with Markforged

Based in Watertown, Massachusetts, Markforged has built a name for itself as a leader in extrusion-based metal and composite 3D printing. The company’s original Metal X system made its debut at CES 2017, offering relatively low-cost metal 3D printing for desktop settings. The flagship machine works by extruding metal powder bound in a polymer matrix, which can then be sintered to grant users fully-dense metal components. The firm has since launched the Metal X Gen 2.

Markforged’s composite printers, on the other hand, are designed to print parts made of carbon fiber, fiberglass, and even Kevlar-reinforced polymers. This includes the X3, X5, and X7 for larger-format parts, and the Mark Two, Onyx Pro, and Onyx One for desktop-level projects.

The FX20 composite 3D printer

According to Markforged, the FX20 is the firm’s largest and fastest 3D printer to date, combining large part production capabilities with high throughput for rapid industrial-grade fabrication. It boasts a print speed up to eight times faster than the rest of the company’s composite printer range, while printing parts up to five times larger than the next largest system, the X7.

To enable high-strength applications, the system features an 80L enclosed build chamber capable of heating up to 200°C, which is crucial for those higher-temperature engineering filaments like ULTEM. The print bed is made of precision machined aluminum and comes with reusable print sheets for faster build changeovers.

Markforged has also equipped the FX20 with a new motion control system that offers closed-loop control through linear encoders, allowing it to move the 3kg printhead with speed and precision. The material bay can store two active XL filament spools, with space for two more in a moisture-controlled environment.

On the software and electronics side, the FX20 has a 7” touchscreen interface, automated calibration and leveling, and a whole host of sensors for real-time feedback on machine performance. Vestas Wind Systems, a sustainable energy firm, has already stated plans to use the FX20 and new ULTEMTM 9085 filament to print high-strength parts for its day-to-day operations.

Jeremy Haight, Principal Engineer at Vestas, said, “The Digital Forge has given Vestas a powerful platform to circumvent expensive and time-consuming conventional manufacturing methodology. When you factor in design iterations, these conventional parts are obsolete in a year or two. With the FX20 and ULTEMTM 9085, we will be able to design and manufacture larger, stronger parts, press a button and take that part right off the print bed to use it.”

Technical specifications and pricing

Below are the technical specifications for the Markforged FX20 3D printer. Both the system and ULTEM 9085 filament are expected to begin shipping worldwide in H1 of 2022 – visit the Markforged website for a quote. Attendees of Formnext will also be able to see the printer at the company’s booth, 12.0 D01, between November 16-19.

| Build volume | 525 x 400 x 400mm |

| Dimensions | 1325 x 900 x 1925mm |

| Weight | 453kg |

| Z-layer resolution | 50 – 250 microns |

| Build chamber temperature | Up to 200°C |

| Touchscreen | 7″ |

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Markforged FX20 3D printer. Photo via Markforged.