Award winning composite and metal 3D printer provider Markforged has made Inconel 625 a compatible material for the Metal X. A nickel-based superalloy, Inconel 625 is remarkable for its propensity to retain high strength at elevated temperatures, and is often applied in chemical, offshore, and aerospace industries. With availability for the Metal X, Markforged seeks to reduce the cost of access to Inconel 625, expand the material’s applications, and deliver lead times competitive with other manufacturing methods.

“Before Markforged, many would have to wait for a contract supplier, invest significantly in mold creation, or purchase a powder-based process that requires intensive facility build-outs and highly trained technicians,” comments Jon Reilly, VP of Product at Markforged.

“Now manufacturing Inconel is fast, safe, and affordable.”

High temperature metals in a compact workspace

The Metal X works using a technique based on standard polymer FFF. Termed Atomic Diffusion Additive Manufacturing, or ADAM for short, the process uses a polymeric material fused with metal powder. The metal content of this material is not required to melt at the extrusion stage of the ADAM process as it is followed by a furnace sintering stage. This is what enables the Metal X system to work with materials containing metal alloys that would otherwise melt at a point well outside its maximum extrusion temperature. Inconel 625, for example, has a melting point exceeding 1000°C.

Other metal alloys currently available for use on the Metal X include 17-4 PH Stainless Steel, A2 Tool Steel, D2 Tool Steel and H13 Tool Steel.

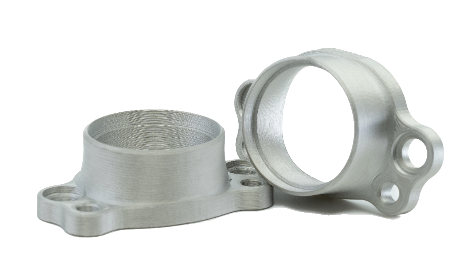

Markforged Inconel 625 application

Markforged Inconel 625 is a nickel-chromium based alloy (with 20-23% chromium content). It has an ultimate tensile strength of 765 MPa, 0.2% yield strength of 334 MPa, and 42% elongation at break (all properties as sintered). Compared to wrought Inconel 625 (AMS 5599) which has 100% relative density, Markforged Inconel as sintered has a relative density of 96.5%.

Sample preparation equipment manufacturer Nieka Systems is the first customer of Markforged’s Inconel 625. Nieka has been using the Metal X to 3D print crucible clips that hold ore and cement samples during rapid cycling. Through testing, the team has found that the 3D printed components have a comparable performance to machined Inconel 625 clips. However, they also enable Nieka Systems to produce the parts in-house, reducing lead times to days rather than weeks, and reportedly making them ten times more cost effective.

“Investing in the Markforged Metal X system to print with Inconel in-house was a no brainer,” said Louis Croisetiere, PhD, Founder of Nieka Systems.

“The metal finish is stunning, and it’s easy to upload the part, get the print running, and if we print five or 10 parts on Monday, we’ll be able to use them a few days later.”

For more of the latest materials news subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook. Seeking jobs in engineering? Make your profile on 3D Printing Jobs, or advertise to find experts in your area.

Featured image shows 3D printed Inconel 625 crucible clips during rapid cycling between low and high temperatures. Photo via Markforged