Desktop FFF system manufacturer, MakerBot, has launched its new experimental LABS extruder for use with its METHOD 3D printer. The LABS extruder converts METHOD into an open materials platform, enabling the 3D printing of a range of third party engineering materials.

Johan-Till Broer, VP of Product Development at MakerBot, stated: “By transforming METHOD into an open materials platform, we provide our users with an incredibly powerful tool to realize their ideas. Engineers can now print a growing number of advanced third-party materials on an industrial 3D printing platform, which was designed to produce stronger and more accurate parts than competing desktop 3D printers.”

He adds, “We have partnered with some of the best material companies in the industry to rapidly expand and diversify the materials portfolio for METHOD. With our partners and customers, we will explore the boundaries of what’s possible with METHOD to unlock new applications.”

METHOD Materials Development Program

The announcement of the extruder follows the launch of the METHOD Materials Development Program, which was announced in November of 2019. The program was set up to allow filament developers to qualify their materials for the MakerBot LABS extruder. Since the program’s inception, a number of leading filament companies have partnered up with MakerBot, including BASF 3D Solutions, LEHVOSS, Jabil, Polymaker, Kimya, and Mitsubishi Chemical.

MakerBot has been actively working with its partners and has yielded the qualification of the following materials: Polymaker PolyMax PC, Jabil PETG ESD, Jabil TPE SEBS 1300 95A, Kimya ABS CARBON, Kimya PETG CARBON, and Mitsubishi Chemical DURABIO, among others.

Dr. Xiaofan Luo, CEO of Polymaker, said, “With more synergy between material and machine we see a greater focus on the applications realized with 3D printing. High temperature materials provide a gateway to production-ready printed parts and the METHOD is the perfect platform to utilize them.”

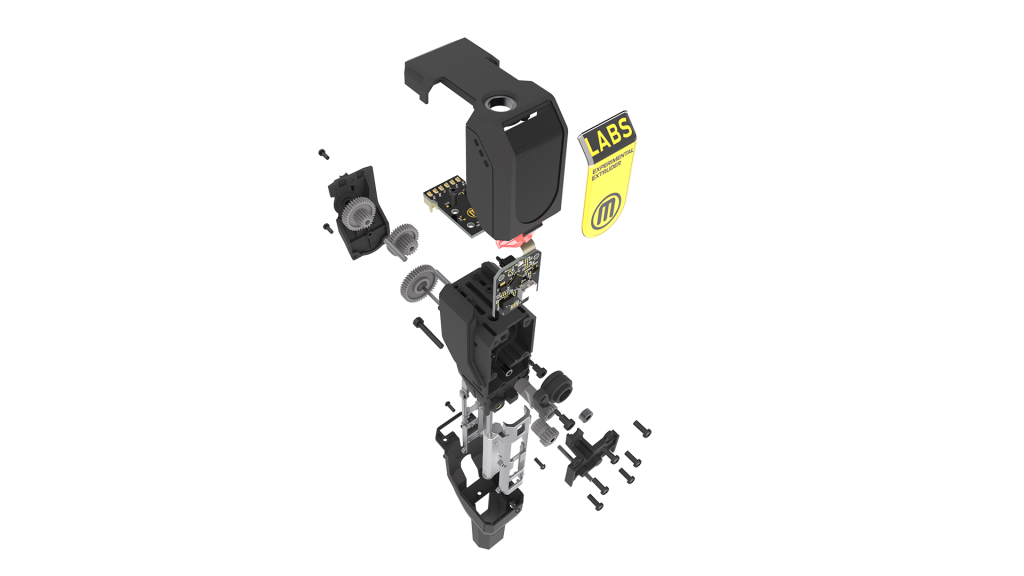

METHOD and the LABS extruder

MakerBot’s LABS extruder is designed to encourage engineers to experiment with new 3D printing filaments on METHOD, in the hopes of discovering previously unthought-of 3D printing applications. With a heated chamber reaching 100°C, METHOD is able to produce strong and accurate parts, making it the perfect complementary system for experimentation. SR-30 supports provided by Stratasys and PVA supports, known for their water solubility, can be used to fabricate complex geometries with minimal post processing. The METHOD is expected to excel at these geometries, which would otherwise be difficult to print on similar systems with engineering materials.

The LABS extruder has a custom hotend, allowing users to explore advanced customization options such as interchangeable nozzle assemblies. Print settings can also be modified for various materials with the system’s unique slicer, MakerBot Print. The hotend of the extruder is capable of reaching 300°C, and houses temperature sensors, material trackers, and an extruder jam sensor.

The METHOD Materials Development Program is one of MakerBot’s many AM related development initiatives. Last year, the company set up its first Innovation Center in New York City at St. John’s University. The opening of the hub also saw 3D printing being incorporated into humanities and science courses at St John’s University’s. Not long before that, the company launched the MakerBot Certification Program, to provide 3D printing design and skills training to middle and high school students.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

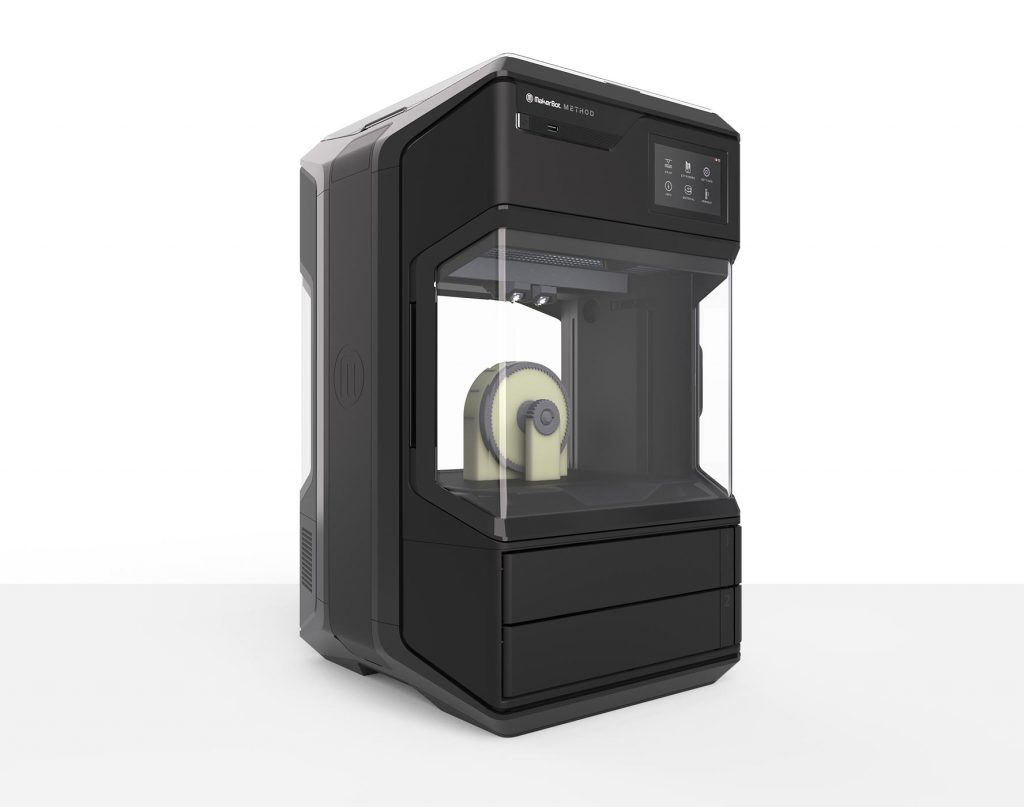

Featured image shows MakerBot METHOD 3D printer. Photo via MakerBot.