Netherlands-based 3D printing material manufacturer Liqcreate has added a new ultra-rigid ceramic-reinforced composite resin to its photopolymer portfolio.

Called the Composite-X, Liqcreate’s latest material is designed to be the strongest in its engineering range, and features an impressive flexural modulus of over 9000 MPa. Once cured, the ceramic-infused resin can become stiffer still, lending it potential applications in the production of heavy-duty automotive or aerospace components.

Liqcreate’s extensive resin range

Liqcreate specializes in photopolymer resin development and production for SLA, MSLA, and DLP 3D printers. Clients utilize the firm’s current material portfolio within various applications, including the fabrication of prototype and end-use parts in the medical, industrial, automotive, and consumer goods industries.

At present, the company’s range includes its premium, creative, engineering, castable, and general-purpose resins, with each featuring different qualities to address a specific target market. Liqcreate’s general-purpose polymers, for example, provide users with a high level of print accuracy and a smooth finish, while its Hazard Glow material yields parts with a unique glow-in-the-dark exterior.

Over the past 18 months, the firm has expanded its portfolio, launching the dental-oriented Liqcreate Premium model in September 2019, followed by its Premium Flex and Tough resins for MSLA/LCD systems. Liqcreate also introduced the Tough-X and Flexible-X polymers last year, which feature strong impact-resistance and rebound properties, respectively.

Now, with the launch of its new Composite-X material, Liqcreate has added an ultra-stiff resin to its portfolio that’s completely different from the rest of its range. The polymer is reinforced by micro-nano particles, providing it with excellent strength characteristics, and once heated, it reacts by becoming significantly more rigid than conventional polymers.

Liqcreate’s stiffest polymer yet

Liqcreate’s reinforced Composite-X polymer has been designed with compatibility in mind, and it should work with most SLA, DLP, and MSLA systems in the 385-420 nm range. The material itself is characterized by high chemical resistance and low shrinkage, but once UV-cured, the firm has shown that these properties can be dramatically enhanced.

For instance, during recent Liqcreate tests, the Composite-X was 3D printed into parts, then UV cured using a Wicked Engineering Curebox for 60 minutes, before being thermally cured for another 2 hours. While the objects featured an initial flexural strength of 140-150 MPa, this rose to 150-170 MPa after heating, representing a significant performance improvement.

Liqcreate’s post-cured parts also demonstrated other benefits, such as increased tensile and compression strength, as well as reduced water sorption. Compared to the firm’s other engineering polymer, the Strong-X, the Composite-X was three times stiffer, potentially making it ideal for demanding aerodynamic applications like wind tunnel testing.

Designing the ideal material

In addition to marketing its set material range, Liqcreate also offers to develop customized resins for clients created for a specific application. As part of the service, customers can request adjustments to a given polymer’s properties, such as its print speed, color, or mechanical properties, to ensure it prints perfectly on their chosen platform.

Effectively, the resin development process goes through four stages, beginning with two initial phases, in which engineers help clients create and evaluate their product plan. Once Liqcreate has started formulating the novel polymer, it then produces samples for customers to assess as well as system parameters, before the final product is eventually shipped.

Given that Liqcreate is an independent manufacturer with sales, R&D, and manufacturing facilities, it’s also able to rapidly scale its production where needed. As a result, the company often targets large scale 3D printing bureaus and manufacturers, with the aim of helping them quickly get their resin to market in quantities that won’t keep their clients waiting.

Recently, Liqcreate has also found that its service addresses dental clients’ needs, and its materials are often used to produce custom aligners. Consequently, although the firm has signed NDAs forbidding it from detailing new projects, it’s clear that its materials’ contact-friendly nature bodes well for the firm’s growth in the lucrative additive dental industry.

Interested parties can find out more about Liqcreate’s material portfolio by visiting its dedicated website here.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our Facebook page.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

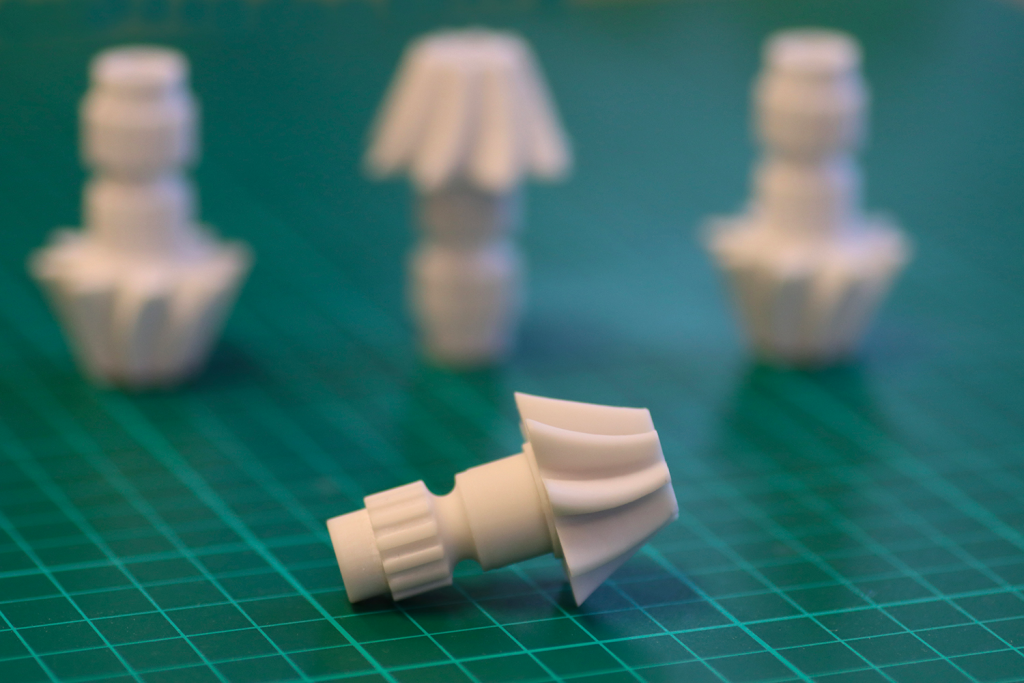

Featured image shows the Liqcreate Composite-X resin and two 3D printed samples. Photo via Liqcreate.