COBOD International, the provider of the BOD series of construction 3D printers, has officially delivered a 10m3 system to Belgian sustainable building company Kamp C. Having completed all relevant training to independently operate the 3D printer, the Antwerp innovation accelerator is now ready to commence its €1.6 million project to build the appropriate infrastructure for additive manufacturing in construction.

Kai Van Bulck, Project Manager of the so-called Co-creation: 3D Printing with Enterprises (C3PO) program at Kamp C, comments, “COBOD International has supplied the printer and the necessary training, but today we are fully capable of operating the printer without the involvement of COBOD.”

“Companies will be able to come here and experiment with the printer until 2020, giving them plenty of time to discover all the advantages of this technique.”

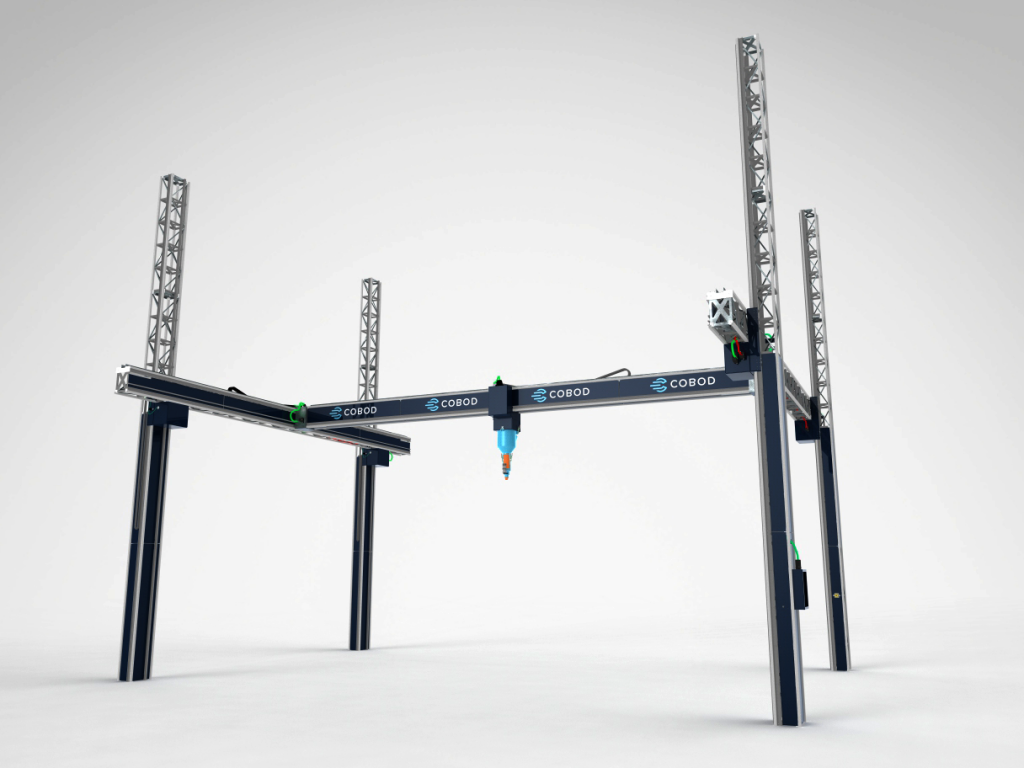

The BOD2 construction 3D printer

COBOD International first won the Kamp C C3PO project contract in 2018. Focusing on building infrastructure for the city of Flanders, under the terms of this contract COBOD was to provide Kamp C with a BOD2 3D printer, and provide all training and support to help get the program off the ground.

A modular unit, the BOD2 is a large-scale deposition system operated via a gantry. Installed at Kamp C, the 3D printer is housed within a temporary shelter of shipping containers.

Kamp C’s version of the BOD2 also includes the optional tangential control print head. Tangential control rotates the nozzle to ensure that concrete is always delivered “tangential to the move direction.” According to COBOD International, “This allows the printer to utilize flaps to control the deposition of material which again allows smoother surfaces and thicker layers.”

The two-story C3PO project

Established with the collaboration of several Belgian organizations, C3PO seeks to introduce the Flemish construction industry to 3D printing technology. So far, Groep Van Roey, ETIB and Beneens, TRiAS architecten and Ghent and Thomas More universities have confirmed their involvement in the project.

An ambitious project, over the next few years C3PO will be working to construct a 2-story building using this 3D printer. Previously, only single-story buildings, such as the BOD “office-hotel” in Copenhagen, have been built using the BOD before. On review of many other 3D printed constructions, e.g. from Apis Cor, Arup and Ynhova, the two-story Kamp C building could also be a first for the industry as a whole.

Van Bulck says, “Here in the beginning we will mainly do various tests and experiments, but later we intend to start 3D printing a 2-story building of our own.”

Jakob Jørgensen, Technical Manager of COBOD, adds, “Kamp C will be the first organization to construct a building on site with a large 3D construction printer not developed by themselves.”

“We are very pleased with the supply to Kamp C and it is great to see that Kamp C now has the experience and competence to set ambitious goals for their use of the printer.”

COBOD International has been nominated for 2019 Startup of the Year in the 2019 3D Printing Industry Awards. Vote now to decide this year’s winners. For all of the latest software news and updates subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Featured image shows the BOD2 3D printer installed at Kamp C. Photo via COBOD International