SOLIDWORKS World continues to demonstrate the capabilities of CAD. With the broad range of software tools enabling industrial additive manufacturing, I interviewed a range of SOLIDWORKS users at the event in Texas this week.

“Unifying the design world”

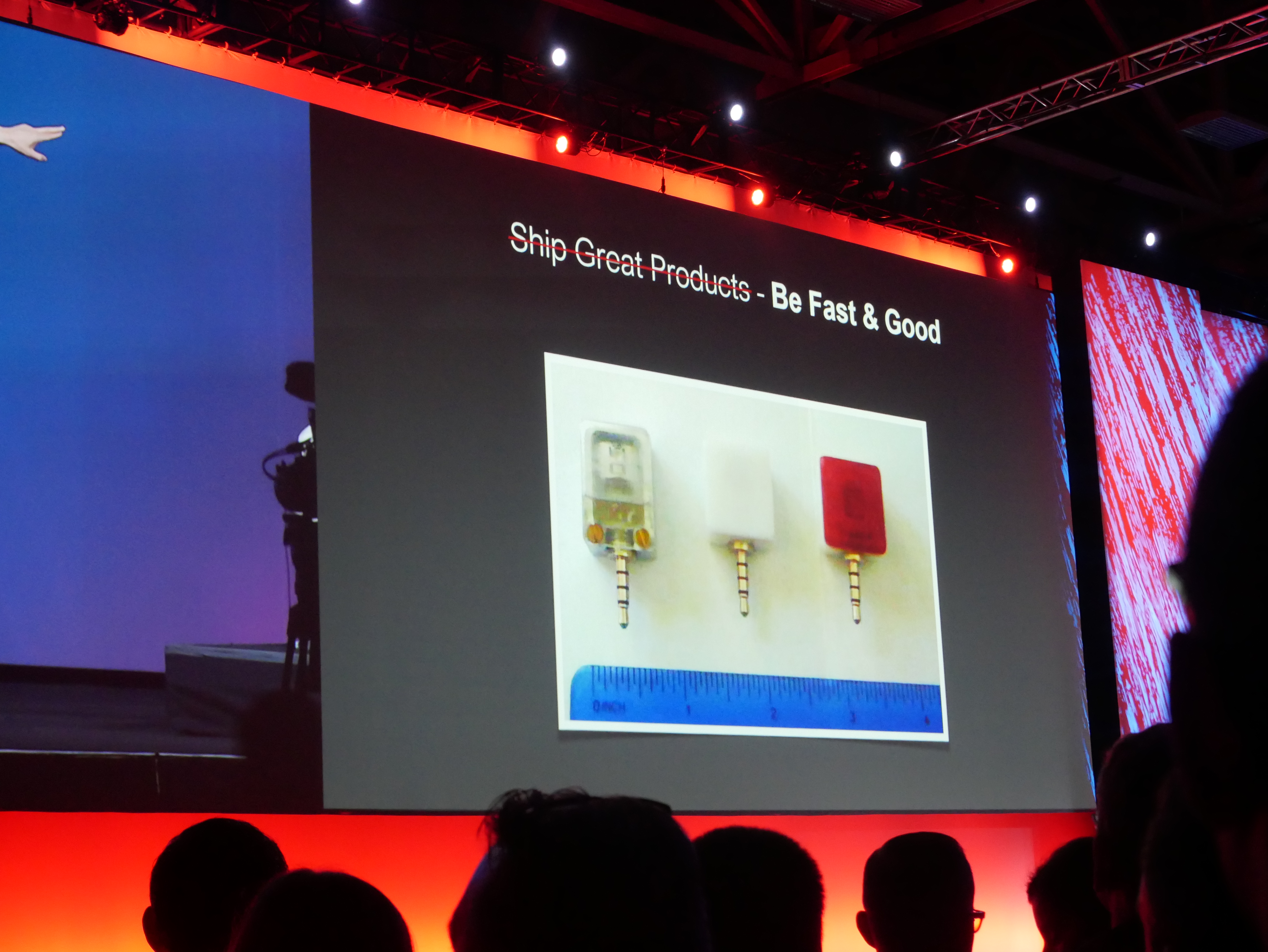

As one of the keynote speaker of SOLIDWORKS World 2019, Jim Mckelvey, Glassblower and co-founder of Square, a manufacturer of card-reading devices for vendors all over the world, emphasized the power of 3D design for product innovation. I sat down with Mckelvey to find out how SOLIDWORKS and 3D printing improved the Square itself, a device for payments.

“SOLIDWORKS is the way to build physical objects. Before, it was AUTOCAD which lived in a 2D world in my mind. I depended on the software for the finite element analysis on the spring in our card reading device.”

“With SOLIDWORKS I could do deflection studies, which otherwise could not be done; it was truly brilliant in the design and testing of the Square. The other important thing that SOLIDWORKS does is unify the design world. I was using a SOLIDWORKS file in California, and our prototypes were being made on the other side of the U.S. as well as Shaoxing, China. Because we were on this platform where everybody is speaking the same language, they knew what I wanted.”

Mckelvey added, “3D printing was used for creating the prototypes, however, I wasn’t pleased with the technology at the time [in 2009], that is, the material and resolution for building substrates, so injection molding was used for the final product. I have high hopes for additive manufacturing, but the software indeed has pushed our product development further.”

Print My Ride

Matt Schmotzer, created Print My Ride Detriot, to display his hobby of 3D printing replica models of roller-coasters. After gaining some traction in the maker community, he shared how he uses SOLIDWORKS to cultivate his passion.

“I’m a field system engineer at the Ford Motor Company by day so I’ve had years of experience with CATIA. However, my education led me to SOLIDWORKS. During my studies at Purdue University, I started to play around with an Invertigo model rollercoaster design which can be seen at Six Flags. When I graduated, I decided to print it out and built it.”

“In my house, I have around 11 3D printers – 6 LulzBot TAZ machines, 2 Flashforge 3D printers and the rest are Form 2 and Form 1+ systems. I also use laser cutters CNC routers and mills.”

“This venture really comes from my passion for cars; although I haven’t monetized it just yet, there are possibilities to turm them into toys or exhibits for museums – and SOLIDWORKS is helping me along the way the journey.”

A toolbox for students

Tertiary students had a notable presence at SOLIDWORKS WORLD. Eliseo Jauregui, a mechanical engineering student, and chief mechanical engineer of the Rover Team at the University of Texas at Arlington (UTA) shared how the software helped create an advanced planetary Rover.

“This rover wouldn’t be possible without SOLIDWORKS and on top of that, we used 3D printing to make high-performance tires – which were inspired by BigRep. The ease of use within the software trumps the other CAD software that I’ve used as a student as it is more intuitive. It’s like a toolbox for us students, you have everything you need – and it comes with instructions.”

“The things I don’t know, I can always figure out from the platform’s help features. I learn something new every time I design, which ultimately makes a better product, or in our case a better robot.”

Nominations for 3D Printing Industry Awards 2019 are open. Let us know the enterprises, technology, and individuals leading the additive manufacturing sector.

Want the latest 3D printing news? Subscribe to the3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Looking for a fresh start this year? Visit 3D Printing Jobs to commence your career in additive manufacturing.

Featured image shows the interior of SOLIDWORKS World 2019. Photo by Tia Vialva.