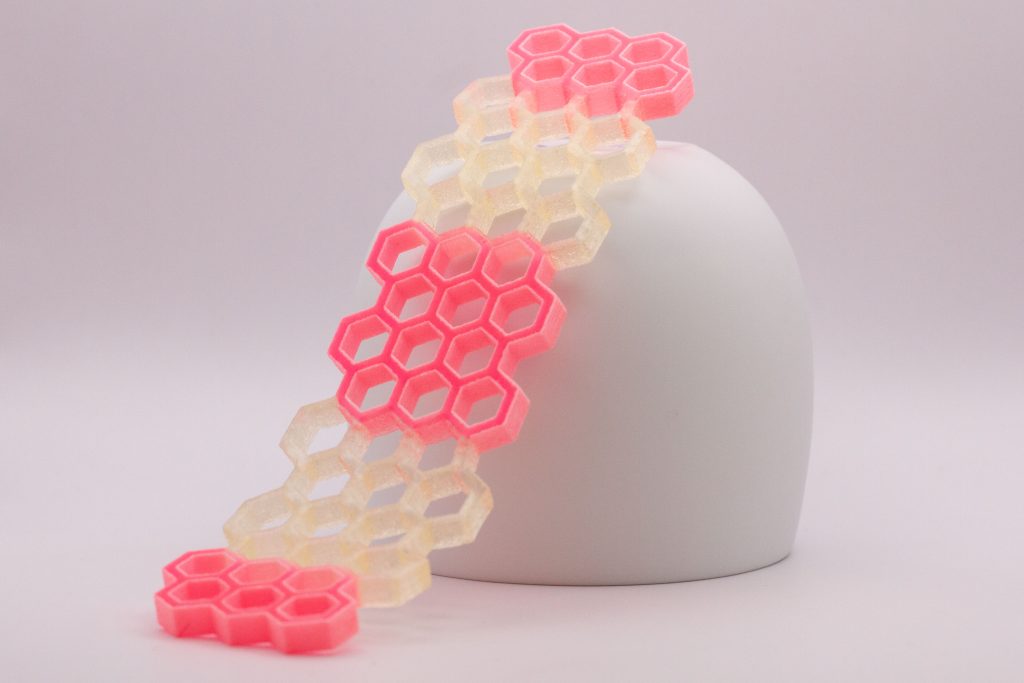

Multi-material 3D printing and “ultra-high viscosity” resin processing capability are at the core of Quantica’s value proposition.

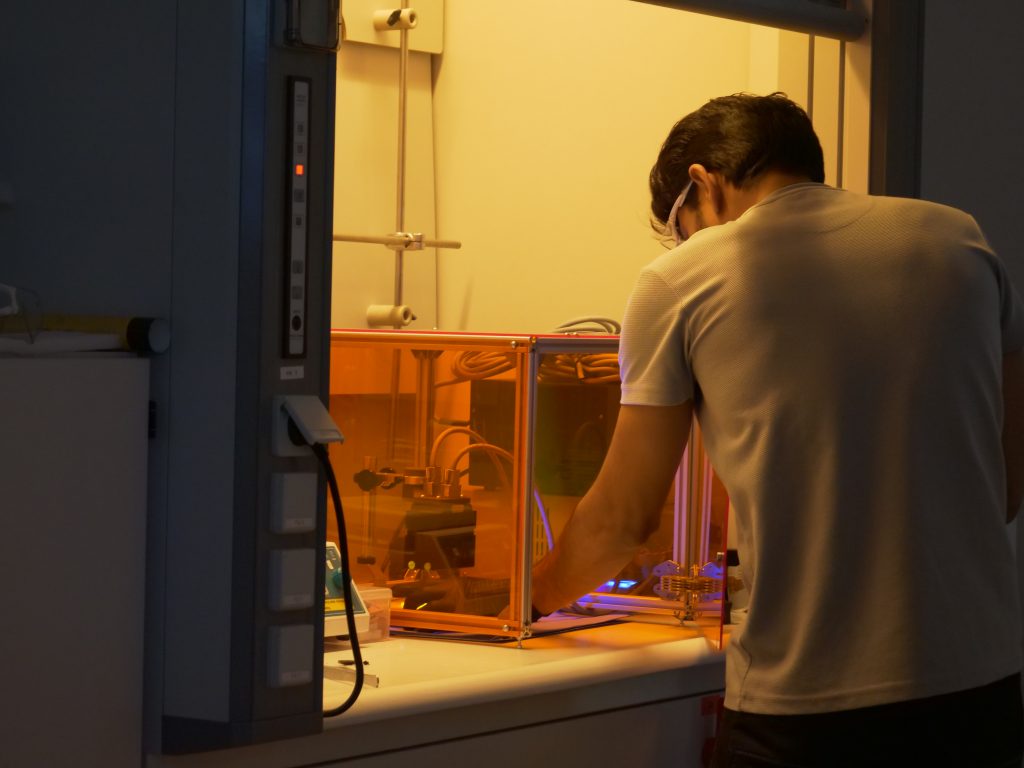

I spoke to Ramon Borrell, the Chief Technical Officer of Quantica, who unveiled the company’s ambitious plans to position its groundbreaking technology in the market. Founded five years ago with headquarters in Berlin, Quantica has rapidly grown to nearly 60 employees, a significant number for a nascent startup, reflecting the intricate technical nature of engine and printer development.

Read more in the 3D Printing Industry Executive Interview series.

Quantica has diligently amassed a cadre of specialists from across Berlin, Barcelona, and Cambridge to surmount the technical complexities inherent in inkjet 3D printing. The recruitment strategy is geared towards bypassing the steep learning curve associated with this domain; as Borrell elucidated, “We are recruiting specialists in all the disciplines that are essential for us. So this is a shortcut in time to achieve our objectives without having to climb the learning curve.”

A significant portion of the funds from their EUR14m Series A round has been allocated towards harnessing talent, which, along with three filed patent families, forms the crux of Quantica’s asset base. These patents underscore the firm’s unique proposition in the 3D printing landscape—a proprietary technology enabling the flexible mixing of multi-materials with high-performance attributes.

Borrell emphasized the company’s unique selling point: “The essential value proposition is the ability to mix multi-materials in a very flexible way with high-performing properties. These high-performance materials can currently only be jetted using our technology, and based on the inkjet market, we anticipate this lead for the foreseeable future.”

The patented technology not only facilitates the mixing of different types of fluids but also significantly expands the range of properties of these mixtures, thereby offering customers an enhanced degree of printing freedom. The unique capability of Quantica’s technology to blend materials with a broad spectrum of properties sets it apart in a competitive market, ushering in a new era of formulation and flexibility in 3D printing.

Quantica Unveils Revolutionary Ultra High Viscosity Jetting in 3D Printing

Borrell delved into the technical intricacies of Quantica’s 3D printing technology, which he believes notably diverges from the industry norm by prioritizing formulation flexibility over high nozzle density. This deviation is a response to the industry’s myopic chase for higher resolution, which Borrell argues stifled formulation flexibility. Quantica’s technology, he notes, is a strategic “necessity trade” designed to buck this trend. “We have this unique capability of ultra-high viscosity jetting, but with lower nozzle count and density,” Borrell explained.

A cornerstone of this technology is an innovatively designed actuator, which creates a deflection in the chamber that’s “100 times larger than conventional” ones, enabling the jetting of materials with a viscosity range previously unattainable in the industry. Borrell elaborates on the significance of this breakthrough: “So you need to do a lot of design changes in dimensions and structure. Also, in how we apply voltage and how we achieve the deflection. That deflection is the one measure that changes the nature of the technology.”

Quantica defines ultra-high viscosity as starting where traditional high viscosity ends—at 100 millipascal second (mPa·s) or centipoise (cP) —and extending up to 400 mPa·s, a range which Borrell claims houses “hundreds, hundreds of materials of interest for 3D printing.” Particle size is another area where Quantica is pushing the boundaries; the printhead can jet particle suspensions up to 70%, with a particle size of 0.1 – 5 microns. This capability has particular interest to the electronics industry.

The resultant expanded materials palette has already spurred collaborations, with Borrell citing a project with a dental company. They aim to leverage Quantica’s technology to print dentures using materials previously deemed unjettable, marking a substantial leap in material application in the 3D printing domain. This innovation paves the way for advanced manufacturing in electronics, enabling the combination of conductive, insulating, and encapsulant materials in a single process to create active electronic components or circuits.

Vote now in the 2023 3D Printing Industry Awards.

Quantica Eyes a Multifaceted Market With Its Pioneering 3D Printing Tech

Quantica’s CTO says the firm plans to significantly broaden the addressable market with its innovative 3D printing technology. Estimating the total addressable market, however, remains a complex endeavor due to the nascent stage of application development. Borrell highlighted the vast potential by referencing several niches, each with a revenue prospect of “seventy or 100 million euros per year.” Yet, the exact scope remains elusive, with Borrell noting, “Two billion euro sales per year in a decade or two is not out of the question, but it’s very difficult to quantify today.”

The dental sector was spotlighted as a massive opportunity, akin to how Align Technology has surpassed the entire 3D printing industry in market cap. Yet, the materials limitation has bottlenecked the dental application of 3D printing to partial process usage. Quantica aims to transcend this barrier, though Borrell acknowledged the high technical and material requirements.

Discussing the technical hurdles faced during technology development, Borrell pointed to the “complexity of the solution” as a major challenge. After concept proofing, the subsequent phase entailed a multidisciplinary engineering endeavor to create an integrated solution. He stressed that post-invention, there’s a whopping “97% of the work left to be done” to achieve market readiness. The journey involved extensive coordination across software, firmware, electronics, and materials development, underscoring the multifaceted expertise required to navigate the intricate path from invention to market introduction.

Quantica’s Technical Roadmap: Bridging Productivity with Multi-material Capability in 3D Printing

Quantica has outlined its medium-term technical milestones. Borrell elucidated the strategic pivot towards boosting nozzle count and jetting frequency. This addresses the “weakest link” of lower productivity, a trade-off they initially made for enhanced formulation flexibility. Borrell estimates a two-year timeframe for “meaningful improvement” in this domain, hinting at a well-charted path toward this goal.

With an eye on precision and system accuracy, Quantica’s launch system is engineered to rival existing 3D printing solutions, particularly targeting high-viscosity photopolymers. The benchmark is set against Digital Light Processing (DLP) technology, aspiring for a print resolution akin to DLP’s 500 to 600 pixels per inch in each direction. “The proposal was let’s achieve the same overall characteristics except with multi-material capability,” Borrell remarked, emphasizing the value addition of multi-material capability without compromising resolution and productivity.

The multi-material angle stands as a cornerstone of Quantica’s value proposition. Borrell rebuffs previous industry skepticism towards multi-material 3D printing, underscoring its indispensability for achieving high aesthetics and complex functionality. He says, “Whenever you are looking [at] complex functionality, always there will be interaction with different materials.”

Moreover, Quantica’s technology presents a compelling case for cost-efficiency. By enabling the printing of both the form and support material, the technology significantly eases post-processing, translating to notable cost and time savings. A case study cited by Borrell revealed that the cost of producing with Quantica’s inkjet multi-material was half compared to using DLP, courtesy of the reduced post-processing expenses.

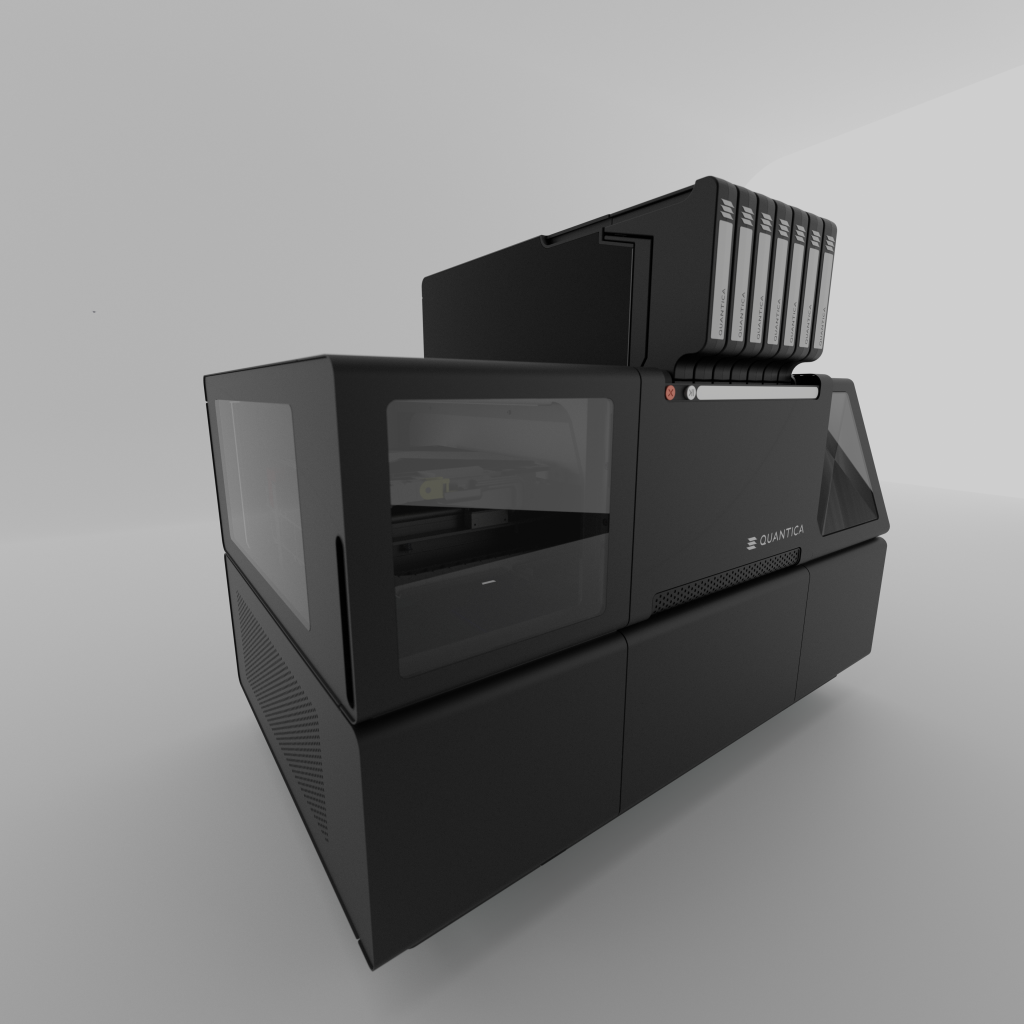

The firm is poised to unveil its first product, the NovoJet OPEN, a printer capable of handling up to seven different materials, by November 2023. He mentioned, “This will be a very interesting tool for R&D departments and industry, developers, and material manufacturers that want to experiment with incredible [capabilities] to learn about multi-material printing, printing with ultra-high viscosity, and they want to develop their own things.”

Post NovoJet OPEN launch, Quantica plans to roll out configurations specifically tailored for certain applications, potentially including multi-color, high-performance materials aimed at creating realistic, durable figures. By 2025, the firm envisions launching a dental printer, co-branded with a partner, which Borrell touts as a “very, very big event.”

While Quantica harbors aspirations towards high-volume manufacturing and series production, these are long-term goals, with Borrell stating, “We want to do that, but it’s not in our short-term plans.” He hinted at potential collaborations with significant industry players to realize these ambitions, emphasizing a collaborative approach toward addressing specific applications and needs in higher industrial use.

Interestingly, amidst these product-centric plans, the conversation also drifted towards a phased-out product, the T1 Pro, which, although not commercialized, continues to serve as an in-house tool for Quantica, shedding light on the firm’s pragmatic approach to product development.

Quantica Unveils Strategy to Outpace Rivals in 3D Printing Arena

As the 3D printing industry evolves, Quantica strives to maintain a unique stance in the multi-material jetting market against competitors like Stratasys, Mimaki, and 3D Systems. Ramon Borrell, CTO of Quantica, sheds light on the company’s tactics to stay ahead in a recent interview. “What we want to do is to stay ahead; by the time somebody finds a way to enter with a high viscosity jetting, we want to be into the second or third generation.”

Borrell also underscores the significance of partnerships for manufacturing, a strategic choice driven by the complex nature of inkjet technology. He mentions a deliberate decision to partner with Xaar Manufacturing to leverage their state-of-the-art facilities and production engineering expertise, stating, “I knew for sure that if we were trying to start manufacturing ourselves from scratch, it would take many, many years until we can put that [product] in the industry.”

On a global scale, Quantica aims to expand its market presence, initially focusing on Europe, followed by swift entries into the Americas and potentially Asia. An exploratory trip to Japan is on the horizon, reflecting Quantica’s keen interest in understanding different market landscapes and identifying strategic partnerships.

Borrell’s exposition paints a picture of a pioneering firm on the cusp of unlocking multi-dimensional market prospects with its distinctive 3D printing technology. The narrative underscores Quantica’s methodical approach to overcoming technical hurdles and its audacious vision of tapping into a myriad of lucrative niches, setting a precedent in the additive manufacturing landscape.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Quantica CTO Ramon Borrell. Photo via Quantica.