In this interview, Olivier Diegerick, the EMEA Additive Manufacturing Software Portfolio Development Executive at Siemens Digital Industries Software, shed light on the firm’s integrated approach towards additive manufacturing (AM) through its software solutions.

Read more in the 3D Printing Industry Executive Interview series.

Siemens’ AM software suite recognizes the role of the AM within a process chain, offering a more holistic solution, beginning with design through Siemens NX, one of the top CAD packages in the market. The suite facilitates a seamless AM workflow even for non-NX users, catering to sectors including aerospace and automotive. Diegerick mentioned, “The uniqueness of our solution is end-to-end going from design optimization to the final product.” highlighting the importance of a unified environment for design, validation, and manufacturing.

A critical feature of Siemens’ suite is its print validation, which allows designers to verify printability early in the design phase, thanks to the connectivity between design, manufacturing, and simulation tools. This robust integration extends to machine interfacing, with direct access to major OEMs’ machine software, ensuring a coherent workflow from platform preparation support generation to process simulation for metal powder bed fusion.

Diegerick emphasized the benefits of this interconnected setup, such as generating compensated models for part deformation and updating data throughout the process. He added, “When you ramp up from an R&D activity towards a more industrialized process, these tools enable data management and are all connected to the initial tool set,” underlining the significance of traceability and process reproducibility in industrial applications.

Moreover, Siemens’ AM software suite incorporates quality control tools, and with connected capabilities, it enables users to simulate their AM activities, including factory setup, before actual implementation. This extensive solution sets Siemens apart from point solution providers operating in silos, thus pushing the frontier in additive manufacturing software solutions.

Voting is open for the 2023 3D Printing Industry Awards; who is leading the industry?

Siemens’ Tailored Approach Streamlines Additive Manufacturing for Industrial Clients

Diegerick illustrated a common scenario where large corporations have disparate AM machines scattered across various global hubs, each employing various design, manufacturing, and simulation tools, often managed through rudimentary means like Excel. He recalled a recent interaction with an aerospace client who admitted to reaching the limits of manageability with such setups, emphasizing the need for a more streamlined approach.

He underscored that most engagements are with brownfields—established firms already utilizing AM to some extent instead of greenfields new to AM.

Siemens’ approach begins with an understanding of a client’s existing process and priorities, whether they lean more towards design or manufacturing. A stepwise implementation of Siemens’ solutions then follows to prevent overwhelming the client, Diegerick explained, “We take this approach because we have a lot to offer, but we can quickly overwhelm our customers by throwing all of our solutions at them.”

Comparing the situation to a management consulting challenge, the discussion highlighted how Siemens navigates through technical and managerial dialogues to optimize AM processes for clients. A typical engagement involves a proof of concept (POC) on the workflow earmarked for optimization, followed by a comparative analysis of key performance indicators (KPIs) between existing and new workflows. The gains are quantified in terms of time, data quality, and traceability, and eventually translated into financial metrics.

Diegerick further mentioned the involvement of Siemens’ consulting division, Advanta, in more complex, strategic discussions with clients. He said, “We have some very smart consultants.” This approach demonstrates Siemens’ commitment to not only providing technical solutions but also ensuring that these solutions align with broader organizational objectives, making a compelling case for a more integrated, consultative approach in the AM industry.

Siemens’ Additive Manufacturing Suite Enhances Traceability and Sustainability for Industries

Siemens’ additive manufacturing (AM) software suite is increasingly finding applications in traceability and sustainability. One notable example Diegerick highlighted is the US-based service bureau Sintavia, which predominantly serves the aerospace and defense sectors.

Furthermore, Diegerick illustrated a unique case concerning sustainability revolving around the use of AM for creating robot grippers at an automotive OEM in Germany. By transitioning from metal to polymer grippers through AM, there was a significant reduction in robot size, contributing to lowering CO2 emissions. He emphasized, “We have some very detailed analysis thanks to the CO2 calculation tools that Siemens also has.”

The interview also delved into the critical matter of traceability, especially in highly regulated sectors like aerospace, defense, and medical. Siemens’ AM suite, integrated within the Teamcenter environment, provides a robust data management solution, enabling comprehensive traceability from the initial design phase to post-processing. Diegerick elaborated, “Every single parameter that happens throughout the process can be stored in this Teamcenter environment. And that’s crucial for our customers today. It’s definitely part of the certification process in aerospace, defense, and medical.”

Navigating Complexities: The Slow March of Additive Manufacturing Towards Industrialization

I asked Diegerick about the slower-than-expected adoption of AM technologies, something he attributes to the complexity and lengthy certification processes involved, especially in the aerospace and defense sectors. Despite the initial hype around AM being a ‘miracle technology,’ industrial companies find it more intricate and time-consuming than anticipated.

Diegerick notes, “Additive brings a lot of advantages, but it takes a lot of experience. It is very complex and I think that’s also why the adoption is slowing down, but it’s taking longer than expected.” The executive mentions that finding and optimizing the right applications for AM, particularly in aerospace and defense, requires a multi-year certification process, making companies hesitant to invest heavily in this technology.

Moreover, the geopolitical and economic uncertainties exacerbated by the COVID-19 pandemic have also slowed adoption. The discussions around Industry 4.0 and global supply chains have spotlighted AM, yet the financial and operational hurdles remain significant. The pandemic has spotlighted AM’s potential in addressing supply chain issues, but consumer spending slowdowns in sectors like dental have affected the profitability of companies in the AM space.

On a broader scale, the industry’s movement towards Industry 4.0 and the digitization of manufacturing processes are slower. Despite the promise of Industry 4.0, the actual transition is encumbered by various factors, including the complexity of AM technologies and the financial implications of adopting them.

Diegerick also discusses the importance of identifying applications that make sense for AM and the subsequent need for design optimization and process stabilization. The journey towards achieving a fully industrialized process, with factories housing tens or hundreds of machines, is proving lengthy and complex.

On the journey of additive manufacturing (AM) towards industrialization, the key lies in identifying applications that make sense for AM, followed by design optimization and process stabilization. However, the process continues; the subsequent journey toward certification is where many companies find a bottleneck.

The landscape is further complicated by the influx of new machines and materials that, while offering new opportunities, also add layers of complexity to the AM adoption process. Diegerick notes the challenges end users face in choosing among myriad options, “When you think you’ve found the right thing, then you see something new.”

Leveraging AI in Streamlining Additive Manufacturing: An Insight from Siemens

The application of Artificial Intelligence (AI) in Additive Manufacturing is gaining traction as industries strive to overcome the intricacies associated with the design and production phases.

Diegerick acknowledges that AM is a highly iterative process often involving a ‘learning by doing’ approach. This iterative nature, coupled with the high costs associated with machine time and materials, underscores the need for AI in optimizing the AM process. Siemens has integrated AI-supported technology in certain tools to expedite design exploration and process simulation.

One such tool, ‘HEEDS,’ aids in design exploration by analyzing hundreds of designs based on preset parameters to identify the one closest to specified requirements. Another tool helps determine the optimal orientation for parts, especially crucial in metal printing, where parameters such as down skin and up skin can significantly affect the printability of the part.

Diegerick elaborates, “With AI, you can find the optimal orientation. AI can save a fortune.” He also mentions the utility of AI in process simulation, which can analyze multiple materials based on numerous parameters affecting the printability of a part.

The conversation also veered towards the broader challenges in AM adoption, with Diegerick emphasizing the importance of identifying suitable applications and the need for standards in the industry to guide newcomers.

While the path to full-scale industrialization of AM presents a complex scenario, the integration of AI promises a reduction in the steep learning curve and resource expenditure, making it a pivotal element in advancing the AM landscape.

Reinforcing Supply Chain Resilience through Additive Manufacturing: Siemens Foresees a Localized Future

Diegerick highlighted the potential of AM in ensuring more localized and reactive supply procedures, a shift from the centralized manufacturing hubs traditionally seen in places like China.

In industries such as oil and gas, the emphasis is on minimizing downtime, which can be significantly reduced by having the capability to print or repair parts close to where they are needed. Siemens Energy has leveraged AM to repair or print gas burners, ensuring a swift response when a gas turbine is down.

The medical sector also stands to benefit immensely, especially in the realm of patient-specific implants. Diegerick notes, “Within, I would say, two or three weeks, they can get a patient-specific implant, and after a couple of weeks more, they’re back on their feet.” This not only underscores the life-altering benefits of AM but also its potential to significantly disrupt traditional manufacturing and supply chain paradigms.

Bridging the Additive Manufacturing Gap: A Call for Stronger Transatlantic Initiatives

On a regional note, the UK, alongside Germany, France, and the Nordics, have been identified as key areas in the EMEA region driving AM adoption, with aerospace, defense, and medical sectors leading the charge in the UK. The geopolitical shifts in recent years have accelerated the pace of AM adoption in the aerospace and defense sectors.

Diegerick noted that while aerospace companies in the UK and France face similar hurdles in adopting AM, the essence of competition thwarts collaborative efforts that could hasten technology adoption. He remarked, “You would wish they could talk to each other and share experiences so that it could go faster. But that’s not possible because of market competition.”

Diegerick underscored the urgent need for stronger initiatives to foster additive manufacturing (AM) adoption in Europe, echoing concerns about the continent lagging behind the US.

A salient point of discussion was the success of America Makes, a US initiative bridging government, academia, and industry to drive AM forward. This initiative stands as a testament to the substantial investment and political will in the US to advance AM. On the contrary, Europe’s efforts must be more cohesive and bold. Diegerick expressed, “It’s always a mix between public and private, and it’s very shy initiatives, in comparison to what America has done, where the government, up to the U.S. President, has said, additive is going to be part of strategic initiatives.”

He advocates for a dual approach, urging EU-level and local-level actions to bolster AM adoption across Europe. The absence of robust governmental backing, both financially and politically, in Europe, as opposed to the US, is viewed as a major stumbling block. Diegerick believes setting up hubs with necessary resources, akin to the US model, could significantly propel AM adoption among European industries.

Diegerick, lamented the narrow perception of tech as merely software in Europe, especially when juxtaposed with consumer tech. He highlighted the shortfall of a more holistic appreciation for AM, encompassing hardware, software, and materials. He remarked, “Tech is just software, but additive is a combination of things. It doesn’t get that same sort of coverage or exposure,” when compared to more consumer-facing tech offerings.

The conversation navigated towards the essence of collaboration in propelling AM forward. Diegerick stressed, “What is important is collaboration.” He underscored the vitality of open dialogues among stakeholders along the value chain despite the inherent challenges posed by intellectual property sensitivities.

Diegerick’s insights serve as a clarion call for a broader understanding and promotion of AM’s multifaceted nature, urging stakeholders to transcend the software-centric narrative. The discourse also accentuates the imperative of fostering collaborative ecosystems to navigate the complex AM terrain, ultimately unlocking the technology’s boundless potential in driving industrial innovation across Europe.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

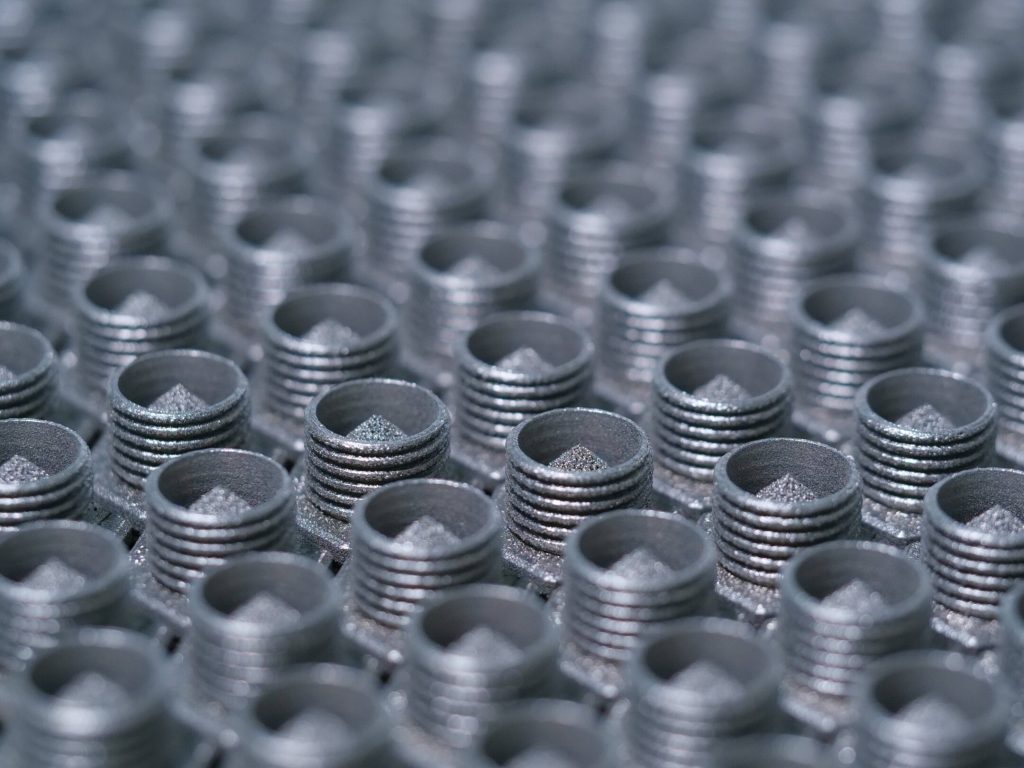

Featured image shows a 3D printed prototype mold designed with Siemens NX. Photo via Siemens AG.