High Speed Sintering (HSS) is a method of end-use 3D printing production 20 years in the making. Professor Neil Hopkinson invented and patented the technology at Loughborough University and, working with Xaar, chose to make the move toward commercialization in 2005.

Recently, at the company’s 3D Technology Day in Nottingham, Neil who is now the Director of 3D Printing at Xaar led a personal tour of the company’s additive manufacturing development and demonstration facility.

Here I was treated to a preview of Xaar’s forthcoming HSS 3D printer, project named ‘Little Blue’, heading to select partners at the end of 2018.

A combination of SLA and injection molding

HSS 3D printing was an idea hatched by Neil studying for his PhD. The project, funded by 3D Systems, looked at the viability of SLA 3D printed molds for use in injection molding. As a matter of course, Neil gradually identified the scope for combining the two processes, cutting out the mold-making middle man, and ramping up rapid prototyping an end-use process.

The technology at the core of HSS development is laser sintering. The analogy Neil gives to that process of using a laser to sinter powder “is almost like using a biro to color in a wall. It’s not an effective route to do that.” He adds,

“How can we find a more effective, time and cost efficient means of converting this powder in laser sintering into a part. And that’s the answer – to take the laser out.”

The carbon black test

Print heads in the HSS process lay an infrared absorbable ink onto the powder bed. When the bed is irradiated, the ink absorbs the energy from the infrared lamp and melts the underlying particles.

Explaining the synthesis of this process, Neil says, “I got some laser sintering powder, two little lumps of it, one was mixed with carbon black, and one wasn’t. I heated them up with a lamp. That one (with carbon black) did, and that one (without) didn’t, and I thought – this is going to work.”

To realize his ideas, Neil needed an inkjet printhead that could withstand the high temperatures needed to fuse polymeric powders. After discussions with a number of printhead producers, it was Xaar that came throught with the support necessary to trial their printheads and, after initially overcompensating on cooling, and literally “frying” the head, it worked.

Inside Little Blue

Xaar’s own “Little Blue” HSS 3D printer is at the alpha stage of development. The current build volume is about the size of a typical house brick. As a demo 10 palm-sized (each approximately 4 in long, 1.5 inches wide and 0.5 inches deep) articulated fish bones were 3D printed.

For a job of this scale and complexity, it takes Little Blue about 2 hours to complete the print.

Plenty more fish still to come

In order to retain this performance, the build chamber is subject to precise thermal stability across the entire build plate, which is the main challenge to scaling up the HSS process.

With development, HSS is intended to be faster than the competition. Speed, and the scale of the system is one of the key R&D goals of Xaar’s sister team in Copenhagen.

“With our Copenhagen team, it’s pretty obvious that we’ve taken them on to build equipment,” explains Neil. “We can’t give specific details of that equipment, in terms of the bed sizes and so-on, but as an industrial system it will be a bigger bed size than this, and it will run quicker.” In a figure of speech adds,

“So that will enable us to build a far greater number of fishes, in a smaller amount of time.”

More inkjet 3D printers the world over

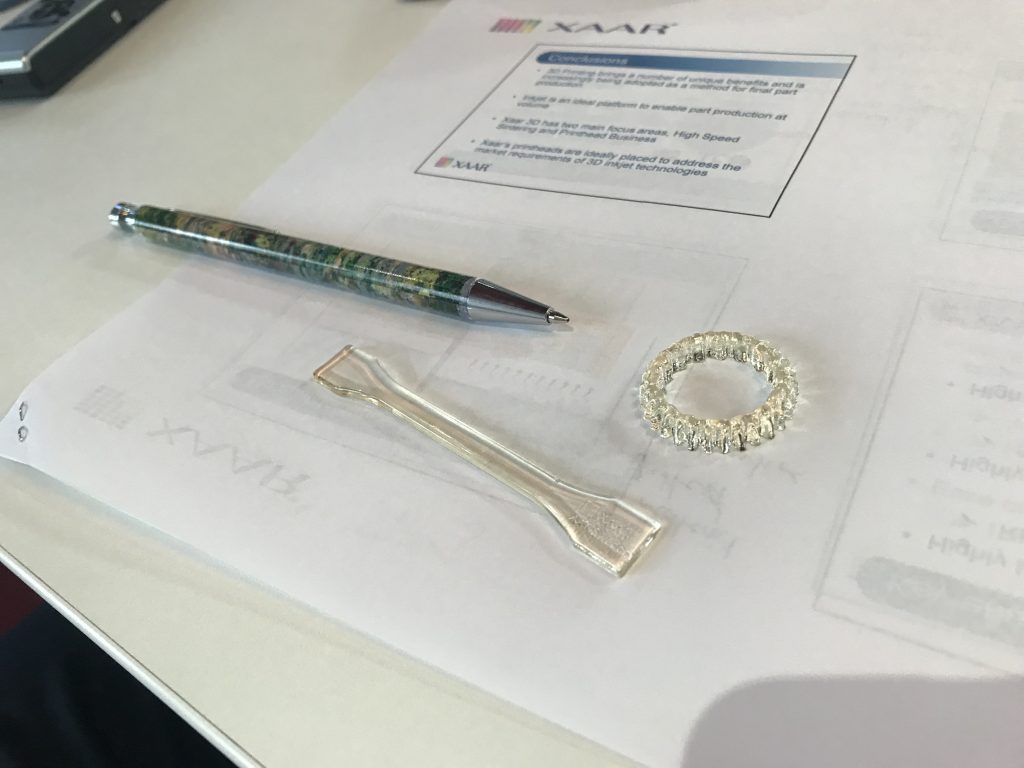

As a technology with strong 2D foundations, many people in the industry believe that inkjet technology will be the future of 3D printing. Keen to make the most of this opportunity, in a second business segment Xaar is also directing its efforts to supply inkjet 3D printheads to international OEMS.

In addition, Xaar has been working with materials manufacturers, including BASF, and other interested parties to test the capabilities of their components.

Xaar’s 2018 3D Printing Industry Awards nominated High Laydown Technology (HLT) is one process at the “heart” of rapid and scaleable additive manufacturing processes. A jetting process that allows for the high throughput of viscous liquids, HLT will also be applied in Xaar HSS systems to get high strength parts and expand its materials portfolio.

To be the first to hear more about recent developments at Xaar and other additive manufacturing companies, subscribe to the leading 3D Printing Industry newsletter. Follow us on Twitter and like us on Facebook.

Kick-start your career – sign up to 3D Printing Jobs here.

Featured image shows Neil Hopkinson, Director of 3D Printing at Xaar, holds a couple manifold part 3D printed using HSS. Photo by Beau Jackson