Continuing with our profiles of the 2020 formnext start-up challenge winners is NematX. NematX was founded earlier this year to focus on next-generation high-performance polymer 3D printing.

Silvan Gantenbein, CTO & Co-Founder NematX, gave this interview to 3D Printing Industry.

3DPI When was your company founded and where are operations based?

SG: NematX is a spin-off company from ETH Zurich, Switzerland specializing in high-performance polymer 3D printing. The company was founded in April 2020 to commercialize the extensive knowledge gathered at ETH in the field of high-performance materials for 3D printing. Being close to a world-leading technical university also gives NematX access to a large pool of well-educated and highly motivated young people to drive further innovation in the highly dynamic AM ecosystem.

3DPI: Can you tell us more about your team’s background and experience with AM?

SG: The core technology behind NematX was developed in the course of my PhD thesis at ETH Zurich. As a materials scientist with in-depth polymer processing know-how, I was looking for a solution to increase the poor quality of 3D printed polymer parts. After intensive evaluation, I came up with an optimized material formulation based on liquid crystal polymers (LCPs) for extrusion-based AM. With this approach, I obtained final part properties that vastly outperformed existing polymer 3D printing techniques.

3DPI: What does your company do?

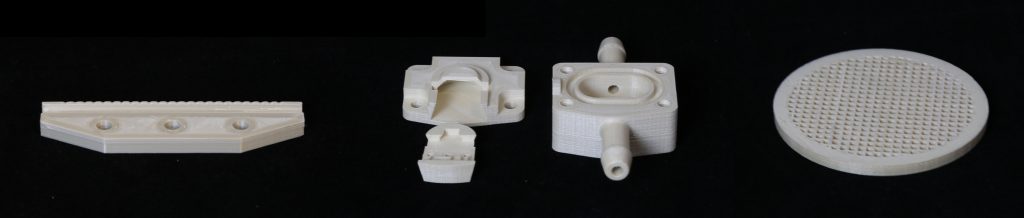

SG: With NematX we introduce the next generation of extrusion-based high-performance polymer AM. With our patented “Nematic 3D Printing” technology we are pioneering the use of LCPs to manufacture lightweight polymeric parts with properties rivaling metal and composite AM. Our parts show ten times higher mechanical properties than current benchmark polymers, superior temperature stability beyond 250°C, and excellent degradation resistance in chemical and biological environments.

3DPI: How does your company fit into the additive manufacturing ecosystem?

SG: NematX follows a systemic approach to AM, with a strong focus on the optimal interplay between materials, hardware, and software to achieve superior part performance from 3D printing. In the current ecosystem, we are best described as an AM service provider with the goal to fully implement our technology into production environments of our customers. For this purpose, we develop custom material formulations and AM processes in close collaboration with our partners in Aerospace & Space, Medical, and Industrial markets to obtain superior performance and cost advantages compared to existing manufacturing solutions.

3DPI: How would you describe the roadmap for your enterprise in the coming years?

SG: Our vision is to offer customers in different industry verticals a competitive AM solution for the on-site production of the highest performing polymer parts. Following our market entry in the Industrial segment, Medical, as well as Aerospace & Space markets, will be further developed. For the latter, very low outgassing and the preserved mechanical damping properties are a big plus. In the Medical field, the inherent biocompatibility of LCP materials and our ability to closely match the mechanical properties of human bone is expected to pave the way for 3D printed, personalized medical devices in the future.

3DPI: Is there anything else you would like our readers to know?

SG: Drop in on us at this year’s (somewhat unusual) Formnext, we’ll be happy to tell you more about our vision or discuss how we can help you realise your ideas. But we are also happy about every visitor who comes by and just says ‘Hello’.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows NematX offers application-specific LCP materials and manufacturing processes for 3D printed high-performance parts. Photo via NematX.