During Formnext 2023, 3D Printing Industry sat down with Maxence Bourjol, Sales Manager at ceramics 3D printing OEM 3DCeram Sinto, to learn more about the company’s semi-automated production line for technical ceramics.

Through its suite of stereolithography (SLA) 3D printers, technical ceramic materials, software, and post processing systems, 3DCeram purports to enable industrial scale production of ceramic parts.

“Something new that we really want to promote at 3DCeram is the ability to use 3D printing not only for prototyping but for the mass production and mass customization of ceramic parts,” explained Bourjol.

At Formnext, the Limoges-based company also showcased CPS 2.0, the newly updated version of its Ceramaker Printing Software platform. Developed over the past two years, this new software has been designed to simplify and optimize the ceramic 3D printing process for industrial users.

Scaling production with 3DCeram’s automated printing line

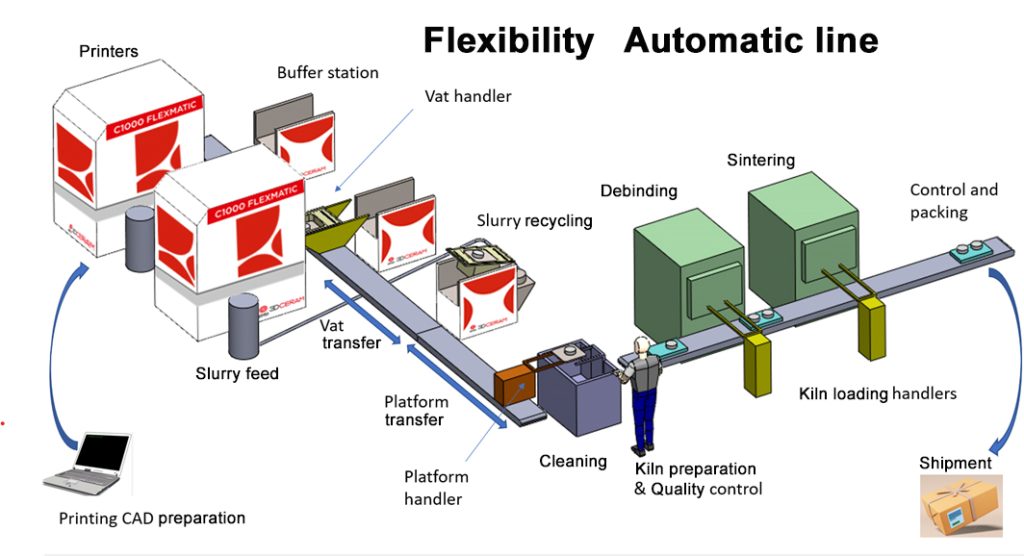

According to Bourjol, the company’s printing line is key to scaling productivity. This manufacturing workflow integrates the company’s 3D printing and post-processing hardware into a semi-automated production line.

“Mass production means that we are not only focused on the 3D printing step, but all stages of the printing line,” stated Bourjol. “This means 3D printing, post-printing, and semi-automation, which decreases wasted time between each step of the process.”

3DCeram’s SLA 3D printers have been designed with large production runs in mind. The company’s C600 Ultimate incorporates a build plate measuring 600 x 600 x 300 mm. According to Bourjol, this build volume can facilitate a production run of 80 parts in just five hours.

Moreover, the C1000 Flexmatic 3D printer has reportedly been optimized to be easily integrated into a semi-automated production setup. This is thanks to its removable tank, which allows for in-line processing of 3D printed parts.

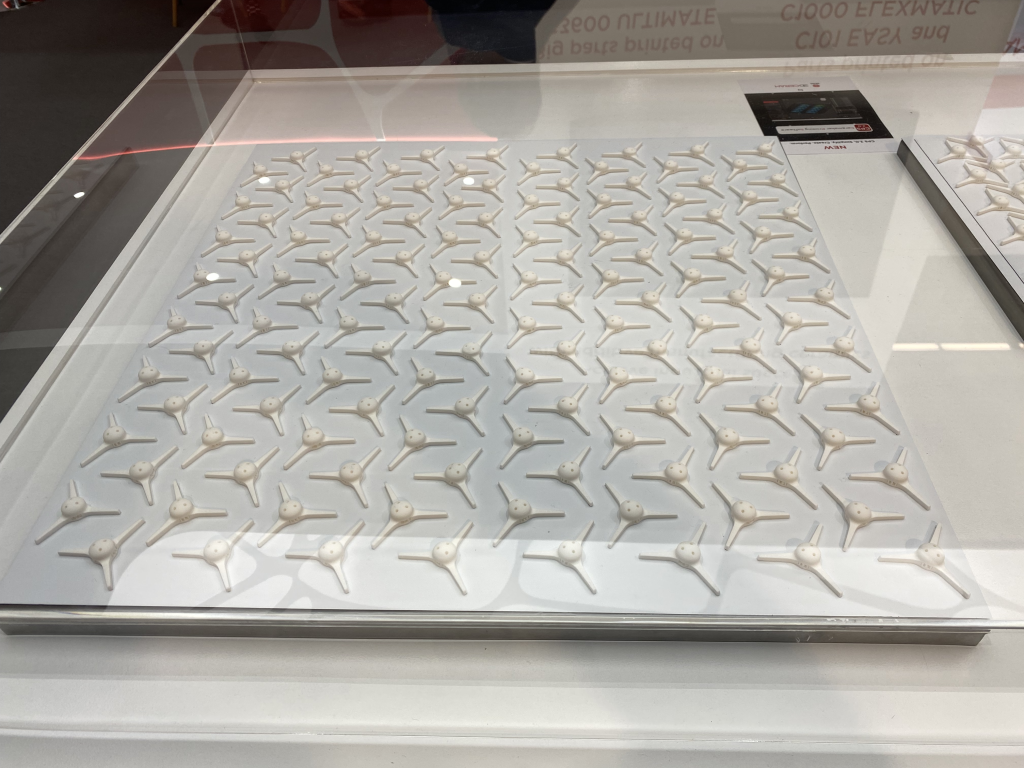

Whilst the scale of each production run is heavily dependent on the size of the part, Bourjol asserted that, for small parts, “you can easily have hundreds of parts on the printing platform.”

However, Bourjol emphasized that the production scale of 3DCeram’s technology is not unlimited. For instance, according to Bourjal, ceramics 3D printing will never compete with the scale offered by ceramic injection molding. “3D printing is not made to produce billions of parts,” explained Bourjol. “But it can be used for large batches of thousands of parts.”

Bourjol highlighted the manufacture of semiconductors as being a notable application of 3DCeram’s printing line. Technical ceramics possess the required properties to meet the material requirements of these electrical components.

As such, in the production of semiconductors, 3DCeram technology is used to produce radiant tubes, wafer boats, gas induction ports, electrostatics chucks, nozzles and rings. The company’s SLA technology can also 3D print ceramic heating components used during thermal treatments. “They need to produce a lot of parts, so they really need our SLA 3D technology for its big 3D printing platform,” added Bourjol.

3D Ceram updated to CPS 2.0

Bourjol also highlighted the key selling points of the recently released CPS 2.0 software update for 3DCeram’s Ceramaker Printing Software. According to Bourjol this update was driven by user feedback from 3DCeram customers.

One key customer request related to making the software more user-friendly. “Our software was very good, but it could sometimes be challenging to use,” explained Bourjol. Therefore, CPS 2.0 incorporates a new user-friendly interface and has been designed with the expressed goal of simplifying the ceramic 3D printing process. Moreover, all 3D printing parameters are pre-loaded into the software, reducing unnecessary delays during the 3D printing process.

This new update also allows several 3D printers to be connected to a singular software interface. “We have customers who have multiple 3D printers. What these customers want is to have one software that can send the 3D printing to all of their 3D printers,” explained Bourjol. “With CPS 2.0, it’s possible to connect our software to as many 3D printers as the customer wants.”

Additionally, Bourjol highlighted that CPS 2.0 allows users to select from a range of experience levels when using the software, optimizing the software for all members of the production line. For instance, designers can access design support when choosing the 3D printing parameters, and 3D printer operators can access designated support when initializing the 3D printing process. According to Bourjol, this makes CPS 2.0 a “more efficient tool for customers.”

Optimizing the production of green hydrogen

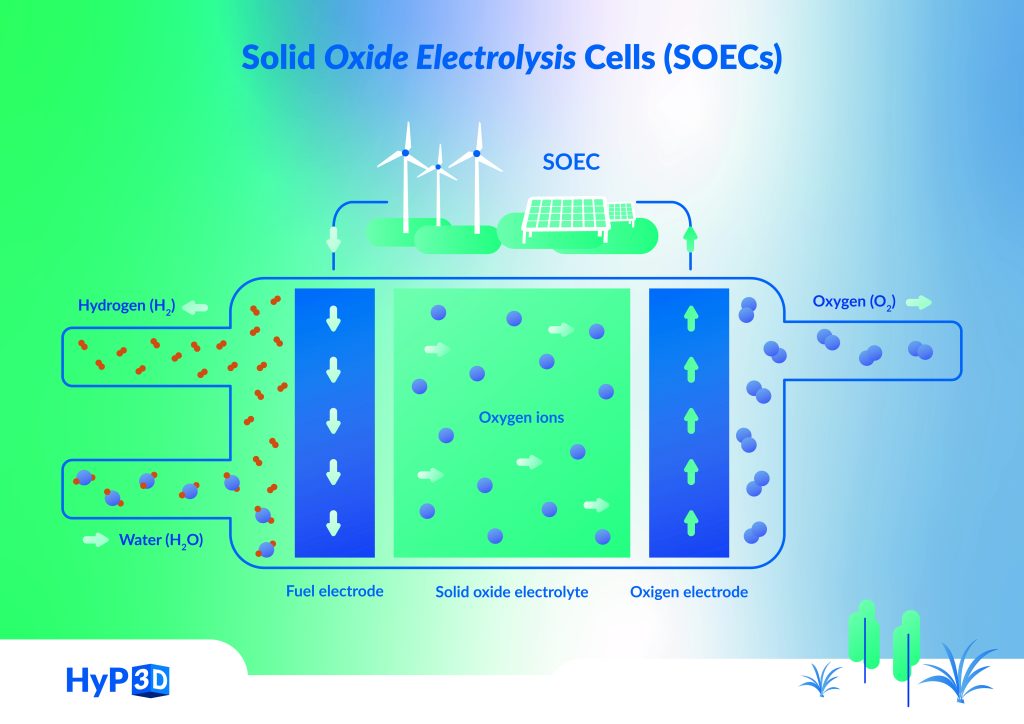

Looking to the future, Bourjol pointed to 3DCeram’s ongoing efforts to leverage its technology in the production of green hydrogen as part of the European HyP3D Project. The goal of this project is to showcase the viability of high-pressure Solid Oxide Electrolysis Cell (SOEC) technology.

This five-year project seeks to develop an ultra-compact, high-pressure SOEC stack capable of converting electricity into compressed hydrogen. 3D Ceram’s role in the project revolves around the production of zirconia Zr8Y parts for the SOEC stacks. According to Bourjol, these parts can not be manufactured using conventional methods.

“With 3D printing, you can do some disruptive design in order to decrease the size of the parts,” explained Bourjol. “Thanks to the complex design, you can also improve the efficiency of the part.”

Moreover, Bourjol pointed to 3DCeram’s industrial-scale production capabilities as playing a vital role in this project. “If all goes well, this project will move into a production scale,” explained Bourjol. “This will require tens of thousands of zirconia parts every month. So the request for the production of these zirconia parts is absolutely huge. This could be a very hot topic for us in the coming years.”

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows 3DCeram’s C1000 Flexmatic 3D printer at Formnext 2023. Photo by 3D Printing Industry.