Time is running out! Nominate now for the 3D Printing Industry Awards 2023.

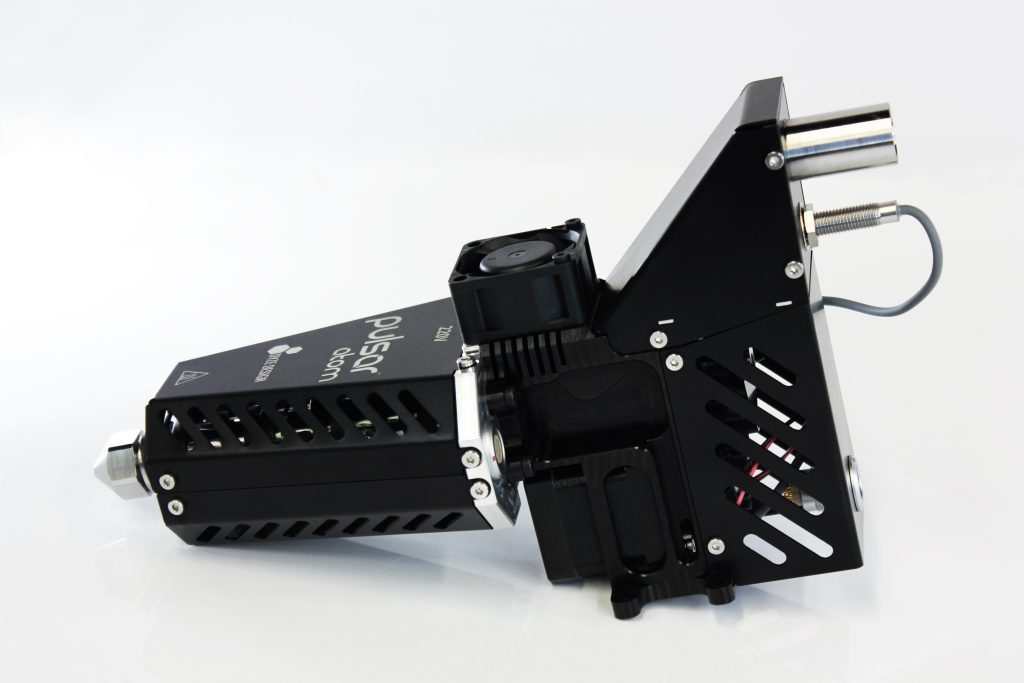

Montreal-based high-performance 3D printer extruder manufacturer Dyze Design has launched the Pulsar™ Atom, a new compact precision pellet extruder.

Offering high precision, productivity, and uncompromising performance, the Pulsar™ Atom utilizes thermoplastic pellets as its raw material and is targeted towards industrial 3D printing applications.

Capable of reaching temperatures of up to 450℃, the Pulsar™ Atom unlocks potential for working with high-temperature materials. Additionally, with a material output rate of 800 grams per hour, Dyze Design’s new extruder allows for high-speed, high-productivity 3D printing.

3D Printing Industry recently spoke with Simon Duchaine, Chief Commercial Officer at Dyze Design, to learn more about the Pulsar™ Atom.

“At Dyze Design, we’re dedicated to empowering 3D printing professionals with the tools they need to excel. Pulsar™ Atom is a testament to our commitment to precision, quality and performance in 3D printing,” commented Duchaine. “Our customers have been eagerly anticipating the launch of Pulsar™ Atom, and we’re excited to bring this technology to the market. We believe it will transform the way industries approach 3D printing, slowly moving away from filament.”

“Pulsar™ Atom’s design is the result of relentless engineering and innovation. We wanted to create an extruder that not only meets but exceeds the demands of industrial 3D printing,” added Philippe Carrier, Dyze Design’s Chief Technology Officer. “With Pulsar™ Atom, we’ve redefined what’s possible in terms of material compatibility, precision, and ease of use. It’s a game-changer for industries relying on 3D printing technology.”

Dyze Design’s growing 3D printing extruder portfolio

The new Pulsar™ Atom adds to Dyze Design’s existing extrusion portfolio, which includes the Typhoon™ high flow extruder, the Pulsar™ large-scale pellet extruder, the DyzeXtruder GT and the DyzeXtruder Pro. However, according to Duchaine, the Pulsar™ Atom marks a clear shift away from these previous extruder offerings, calling it “a completely different technology.”

“Our DyzeXtruder GT and Pro are suited for desktop format machines with high temperature needs. They are using filament as the source material and don’t address the need for high flow rate (fast printing times),” explained Duchaine. “Atom, on the counterpart, is using granules/pellets as the source material, is a bit taller (we’re talking 25cm) and stiffer.”

Unlike the company’s previous extruders, Duchaine stated that the Pulsar™ Atom is “really targeted towards professional/larger scale machines needing a high throughput to address the problem of slow print time on large build volumes.”

A high temperature extruder with wide material compatibility

Central to the Pulsar™ Atom is its high-temperature capabilities, with an ability to heat up to 450°C. Two high-fidelity PT100 sensors are also included with the extruder. This ensures accurate extrusion temperature control, with a sensor added to each of the two independent heaters within the Pulsar™ Atom’s heatcore.

Thanks to its heating capabilities, the Pulsar™ Atom offers wide-ranging material compatibility. “Simply put, you can extrude any thermoplastic, composite or elastomer material you can find,” explained Duchaine. However, “some materials are really better suited for additive manufacturing, you definitely need to take that into account (warpage, bed adhesion, etc).”

Duchaine also outlined the material-efficiency benefits of pellet-based 3D printing over alternative additive manufacturing methods.

“You can save up to 10x on the material cost. For PLA it’s a bit less, but you still save up to 3 times the cost. By using the raw material they use to make filament, you remove that third-party, saving costs,” stated Duchaine. “There’s also a whole new world opening up regarding sustainability. With pellet-based extruders you can use recycled material and, having the right equipment on hand, you could reuse your own plastics.”

Dyze Design’s new extruder also possesses exceptional heat resistance, and can withstand temperatures of up to 150°C. As such, the Pulsar™ Atom ensures durability and reliability in demanding high-temperature environments.

“Pulsar™ Atom represents a leap forward in industrial and pellet-based 3D printing. Its ability to reach temperatures of up to 450°C while withstanding temperatures of up to 150°C opens up a world of possibilities for professionals looking to push the boundaries of what they can manufacture using thermoplastics,” added Duchaine.

“The exceptional heat resistance of Pulsar™ Atom ensures that it can handle the most challenging environments. It’s a tool designed for professionals who require reliability and precision.”

Dyze Design also offers liquid-cooling options for the Pulsar™ Atom. Liquid-cooling blocks and high-temperature connectors can be added to the extruder, optimizing performance and longevity in high-temperature environments.

Fast and reliable extrusion for a range of applications

Consistency and reliability is assured by the Pulsar™ Atom’s 1.5 compression ratio, ensuring consistent and reliable extrusion across a wide range of thermoplastics. The extruder also provides a mass flow stability of less than 5%, ensuring precision and quality in every 3D print.

Additionally, the Pulsar™ Atom delivers between 0.8kg and 1kg per hour of material output, accelerating production time and optimizing productivity. Dyze Design also offers an optional automatic pellet feeding system, which can be integrated with the Pulsar™ Atom to streamline the 3D printing process.

Dyze Design’s new offering also provides flexibility and meets diverse 3D printing needs, thanks to its wide-ranging nozzle sizes of between 0.4mm to 2.5mm. Optimized for 2.75mm/3mm potato-shaped pellets, the Pulsar™ Atom ensures reliable clog-free extrusion.

A compact system, the Pulsar™ Atom weighs less than 1.5kg and stands at under 245mm in height. This allows for easy integration into an existing manufacturing setup. Indeed, the Pulsar™ Atom is an accessible and versatile option, with users able to choose from 110V and 220V power supply to meet their local power requirements. What’s more, the extruder offers seamless integration with open-source firmware and popular 3D printer controller boards such as Duet3D and BTT SKR.

The Pulsar™ Atom is well suited to workflows utilizing either 3D printers or robotic arms. Indeed, with regards to robotic arms, the extruder offers over 45 degrees of liberty around the nozzle for robotic applications and non-planar 3D printing.

In terms of applications, Duchaine highlights the medical and architectural sectors as being key. “Compared to the Pulsar large-scale extruder (our original pellet extruder) which was targeting LSAM (large scale additive manufacturing) and fields like aerospace and automotive, the Atom is scaling down a bit on the applications”

Duchaine added that the Pulsar™ Atom is “trying to bring a bit of “high flow printing and fast print” in the “precision and quality” 3D printing work.”

Technical specifications and pricing

Pricing for the Pulsar™ Atom starts at around $3,700 USD. However, depending on additional options and the extruder’s configuration, prices can rise to $4,430 USD.

Prospective customers can visit the Dyze Design website for inquiries, preorders, and additional information.

| Weight | Less than 1.5kg |

| Height | Less than 245mm |

| Flow Rate (Output Flow) | 800g per hour (results from alpha version testing, actual output flow of the current release version may vary) |

| Nozzle Sizes | 0.4mm, 0.6mm, 0.9mm, 1.2mm, 1.8mm, 2.5mm |

| Voltage | 110V or 220V |

| Max Environment Temperature | Up to 150℃ |

| Max Operating Temperature | Up to 450℃ |

| Ideal Compatible Pellets | Less than 3mm, rounded shape |

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows Dyze Design’s new Pulsar™ Atom extruder. Photo via Dyze Design.