Time is running out! Nominate now for the 3D Printing Industry Awards 2023.

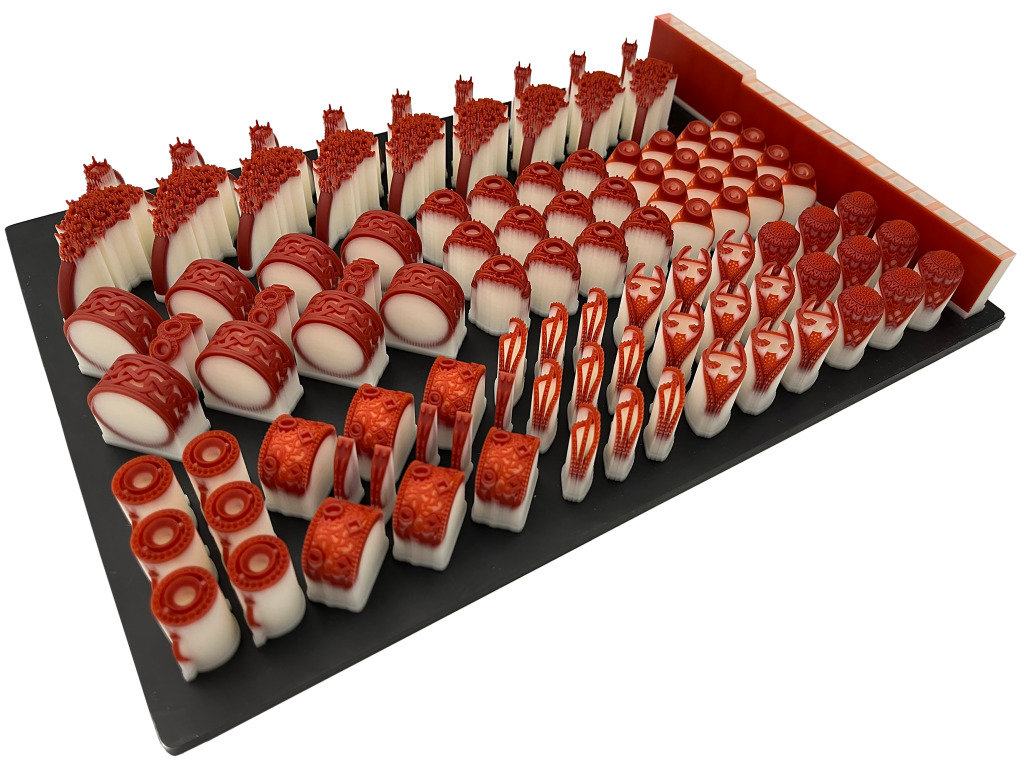

US-based 3D printer manufacturer 3D Systems has announced the launch of its new MJP 300W 3D printer and VisiJet Wax Jewel Ruby material.

Adding to the company’s end-to-end jewelry manufacturing portfolio, these new offerings are designed to address the growing global jewelry market which is set to exceed $22 billion by 2030.

The combination of these two new products is said to allow wax jewelry pattern producers to more efficiently achieve greater design freedom and improved surface finish.

The MJP 300W jewelry 3D printer is said to offer improved 3D printing speeds, surface quality, and reliability. Incorporating two new build modes, the MJP 300W is being billed as 3D Systems’ most advanced and flexible wax 3D printer to date. The new 3D printer reportedly offers enhanced productivity, efficiency, quality, and design freedom for jewelry manufacturing workflows.

Additionally, as a tough, temperature-stable pure wax, VisiJet Wax Jewel Ruby is said to offer optimal flexible material properties and good dimensional stability in high-temperature environments. 3D Systems claim that its new material maintains the details of intricate jewelry designs during the molding process, reducing the likelihood of breakage or distortion.

“With the introduction of the MJP 300W and our new VisiJet Wax Jewel Ruby material, we are providing producers of wax jewelry casting patterns with enhanced capabilities to improve productivity and processes that ensure reliability,” commented Marty Johnson, Vice President, product & technical fellow, 3D Systems. “3D Systems’ full system integration of the materials, printer, print process, and software which is strengthened by our application expertise and global customer success team is enabling our jewelry manufacturing customers to achieve new levels of innovation, quality, and reliability.”

“The latest additions to our end-to-end solutions for jewelry manufacturing reinforce our commitment to addressing our customers’ needs to gain unprecedented levels of agility with ease of use that ensures high-quality results at any scale.”

Both the MJP 300W and VisiJet Wax Ruby will be available to purchase in November 2023.

The MJP 300W: 3D Systems’ newest jewelry 3D printer

The launch of the MJP 300W has seen 3D Systems introduce two new 3D print modes, QHD and UHD.

QHD mode is said to enable premium quality surface finish. According to 3D Systems, QHD mode offers more than 50% improved resolution in all axes (i.e. 2,000 dpi in X, 1,800 dpi in Y, 2,900 dpi in Z) and 9.5µm layer thickness, compared to the company’s previous generation wax 3D printer.

QHD mode is also said to facilitate the 3D printing of more complex designs where polishing is impractical or impossible.

The new UHD mode allows for high-speed 3D printing, offering 2x faster 3D print speeds than XHD on the ProJet MJP 2500W Plus which was launched earlier this year. As such, UHD mode reportedly increases throughput and reduces the labor required for finishing and polishing.

In addition to the two new 3D print modes, the MJP 300W also offers XHD and ZHD 3D print options. With four 3D print modes, this new 3D printer reportedly offers improved flexibility in build planning for both day and night shifts to meet the speed, geometry, complexity, and surface quality of all design styles.

3D Systems has also added an industrial stack light to the MJP 300W, increasing the ease at which users can monitor 3D print jobs. This light can be positioned to offer greater visibility on the printer or an adjacent work surface.

The company has also made 3D print head and hardware modifications to improve the 3D printer’s reliability. This will increase uptime by decreasing replacement frequency, lowering the cost of ownership in the process, 3D Systems claims.

3D Systems’ new VisiJet Wax Jewel Ruby 100% wax material

3D Systems is billing its new VisiJet Wax Jewel Ruby as the company’s most advanced material for 3D printing durable patterns for high-quality jewelry pieces. Indeed, patterns produced with this new material are said to possess increased thermal stability compared to the company’s VisiJet Wax Jewel Red material.

Patterns 3D printed using VisiJet Wax Jewel Ruby also exhibit high levels of durability. Therefore, these parts are unlikely to break through normal handling and maintain their dimensional stability through shipping. The new material also enables pre-setting of stones, accelerating the 3D printing process.

“We were pleased to have early access to this material for our jewelry manufacturing applications. Our experience has shown that it is very easy to handle, and delivers patterns with improved strength and flexibility, enabling us to provide higher quality, durable patterns to our customers,” stated Shashidhar Kumar, partner at Shree Rapid Technologies.

“Additionally, the material is best suited for pre-setting stones, which is helping our customers improve efficiencies when creating pieces with intricate details.”

3D printing and the jewelry industry

The use of additive manufacturing within the jewelry industry is growing. A report released by Contrive Datum Insights in March 2023 outlined the total addressable global market for 3D printed jewelry as being over $8 billion in 2022. This is expected to reach more than $22 billion by 2030.

3D Systems is not the only company to explore this growing market. Last year, multinational printing firm HP partnered with precious metals specialist Legor Group. This collaboration sought to advance metals science and the production of stainless steel accessories for the jewelry and fashion sectors.

The partners worked together to develop novel precious metal materials for HP’s Metal Jet system. These materials were designed to provide speed, quality, and cost advantages for the rapid production of 3D printed jewelry and fashion accessories.

Elsewhere, Italian luxury jewelry supplier Promotion SpA adopted INTAMSYS additive manufactured tooling to optimize its product assembly process. Leveraging INTAMSYS technology, Promotion SpA 3D printed bracelet alignment tools. These tools were capable of withstanding multiple testing cycles, without scratching the bracelet’s fine exteriors.

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows 3D Systems’ new MJP 300W jewelry 3D printer. Photo via 3D Systems.