Researchers from MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) and Columbia University have developed a new CAD software plug-in that optimizes the 3D modelling process.

The main concept behind the InstantCAD software, hence the name, is ease and speed of use. The paper cites the fact Computer Aided Design (CAD) software is a multi-billion dollar industry and intrinsic in designing nearly all manufactured shapes in the world.

Aerospace company Boeing has just validated these claims by signing a billion dollar contract with CAD software providers Dassault Systèmes.

Accessibility

Lead author of the paper Adriana Schulz explains that while CAD software has such an intrinsic role in the world of manufacturing, the process could be simplified,

“In a world where 3-D printing and industrial robotics are making manufacturing more accessible, we need systems that make the actual design process more accessible, too,”

Addressing this with InstantCAD, the team “hope to be paving the way to a new age of personal manufacturing and DIY design.” In addition to improving the process for CAD veterans, the software is also intended to benefit entry level users.

Schulz’s paper will be presented at computer graphics conference SIGGRAPH in Los Angeles alongside the water dipping 3D scanning research.

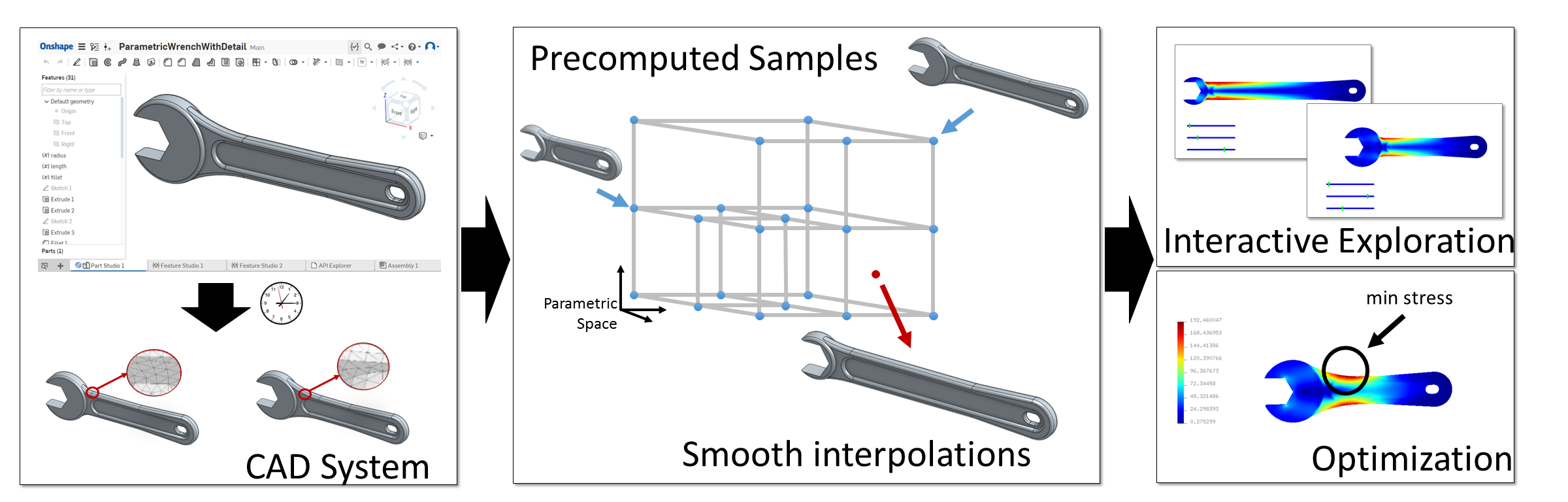

InstantCAD workflow

InstantCAD works as a plug-in for existing CAD software and thereby extends the functionality of such platforms.

The software uses a cloud platform, so once an object is designed in a CAD system it is sent to InstantCAD which allows for simultaneous geometric simulations and evaluations.

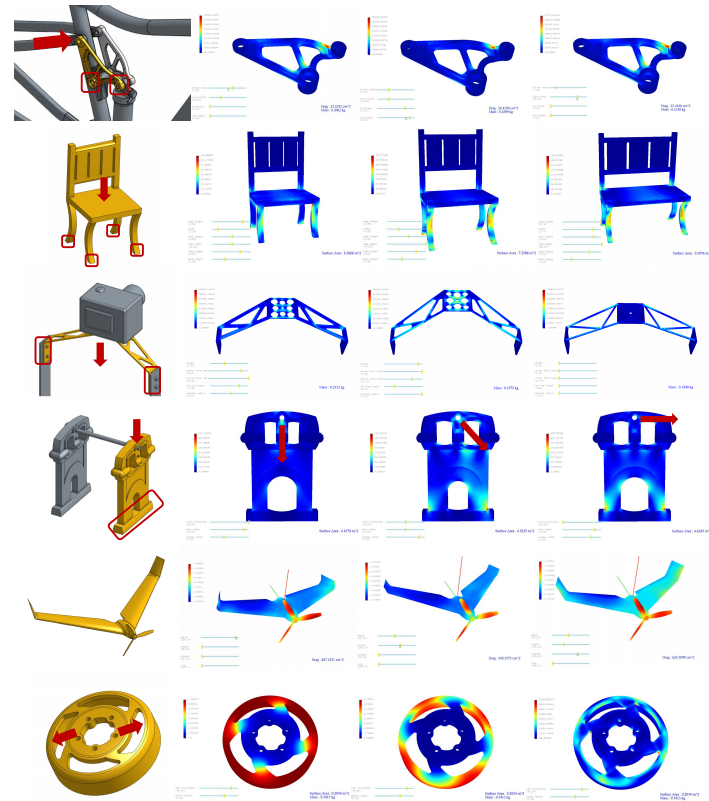

The software has two main processes, interactive exploration and automatic optimization. Interactive exploration allows the user to test design changes and simulate the effects on performance. While automatic optimization allows the user to enter predetermined parameters and generate an optimal design in a similar way to generative design software.

Interpolation

The InstantCAD system is enabled by an interpolation process. Schulz explains “It’s too data-intensive to compute every single point, so we have to come up with a way to predict any point in this space from just a small number of sampled data points.”

“This is called ‘interpolation,’ and our key technical contribution is a new algorithm we developed to take these samples and estimate points in the space.”

Industrial application

With use of interpolation, the InstantCAD process allows tweaking of designs to take place much quicker. Adriana Schulz believes this means the process bodes well for significant industrial application,

“We think this could be a real game changer for automakers and other companies that want to be able to test and improve complex designs in a matter of seconds to minutes, instead of hours to days.”

But it’s not just about speed as CSAIL Associate Professor Wojciech Matusik explains. Matusik believes InstantCAD “has the potential to dramatically improve the quality of the products themselves.”

“The more complex your design gets, the more important this kind of a tool can be.”

The paper, titled ‘Interactive Design Space Exploration and Optimization for CAD Models’, has been published in the ACM Transactions on Graphics journal.

If you are looking for a career in additive manufacturing, take a look at our 3D printing jobs. And be sure to check out all the latest 3D printing events.

Subscribe to the 3D Printing Industry newsletter to stay up to date with all the latest 3D printing research news, follow us on twitter and like us on Facebook.

Featured image shows Adriana Schulz demonstrating the InstantCAD software. Photo via Rachel Gordon/MIT CSAIL.