Multi-material 3D printer developer Inkbit has showcased its Vista AM system and its capabilities to mass-produce high-end 3D parts at RAPID + TCT 2023.

The Inkbit Vista AM system relies on a closed-loop feedback control system that utilizes vision-based technology to achieve high precision, repeatability, and dimensional accuracy. This enables the system to manufacture parts with the same level of precision as conventional machining, while also taking advantage of the adaptability and flexibility of additive manufacturing. Additionally, the system offers an array of materials that are free of acrylate and can be used to produce parts with diverse properties such as exceptional durability, chemical resistance, softness, and flexibility, suitable for industrial-grade production.

“We are thrilled to be exhibiting at RAPID + TCT again this year,” said Davide Marini, CEO of Inkbit. ” With Inkbit, you can have the precision you need with the flexibility you want. Our technology is enabling manufacturers to produce accurate, repeatable parts at genuine production volumes and speeds. Since last year’s show, we have announced new materials and gained new customers, and we’re excited to share all this with the RAPID + TCT community.”

Featuring the Vista AM system

The Inkbit Vista AM system features Vision-Controlled Jetting (VCJ), a “state-of-the-art” technology that leverages machine vision and AI algorithms to regulate material deposition in real-time. As a result, the system can manufacture parts with superior dimensional accuracy and precision.

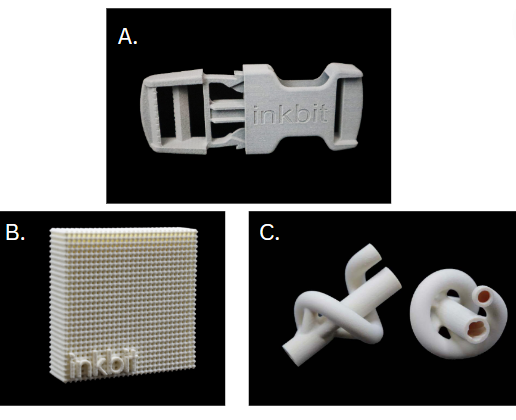

Designed specifically for large-scale production, the Vista AM system can produce up to 100 parts per day and is compatible with a diverse range of materials, including high-performance polymers, elastomers, and composites. This versatility makes it ideal for various applications, including medical devices, industrial tooling, and consumer products. Inkbit believes its Vista AM system represents a significant technological advancement in additive manufacturing, thanks to its “unparalleled” combination of speed, precision, and adaptability.

Inkbit’s material product line

Titan Tough Epoxy 85 is a high-performance material that is designed to withstand heavy wear and tear. Its novel formulation allows it to deliver “exceptional” mechanical properties, making it ideal for applications that require both accuracy and production-grade durability. The material’s mechanical properties are comparable to those found in commonly used AM thermoplastics, making it a suitable choice for applications that require individual components to be precise for proper assembly.

Vulcan Soft Elastomer 30 is an elastomer with a stretching ability of over 180%. The elastomer family has a low shore hardness of as low as 30A, which provides a soft-touch feel, making it a suitable choice for applications that require skin contact. Vulcan Soft Elastomer 30 can be used in various applications, such as seals, gaskets, and grippers, due to its versatility. Its flexibility and softness make it a dependable solution for applications that demand these properties.

Titan Chem Epoxy is an epoxy material with superior resistance to various organic solvents and basic solutions. It provides high stiffness and tensile strength and can maintain its properties even at temperatures as high as 120°C. These properties make it a suitable option for various applications that require chemical resistance and mechanical strength.

Technical specifications and pricing

| Print Engine | Vision-Controlled Jetting (VCJ) |

| Build Volume (X, Y, Z) | 500 mm x 250 mm x 200 mm19.6 inch x 9.8 inch x 7.8 inch |

| Concurrent Materials | Four (three engineering, one support) |

| Dimensions & Weight | 2.8 m x 1.5 m x 2.4 m approximately 1,500 kg |

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Inkbit Vista 3D printer. Photo via Inkbit.