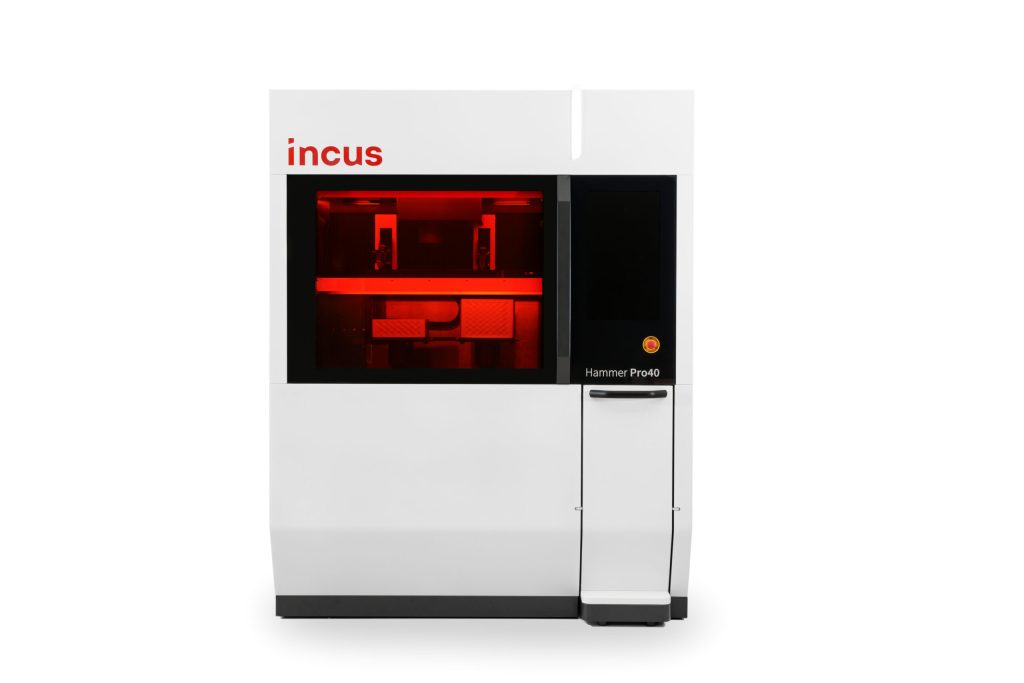

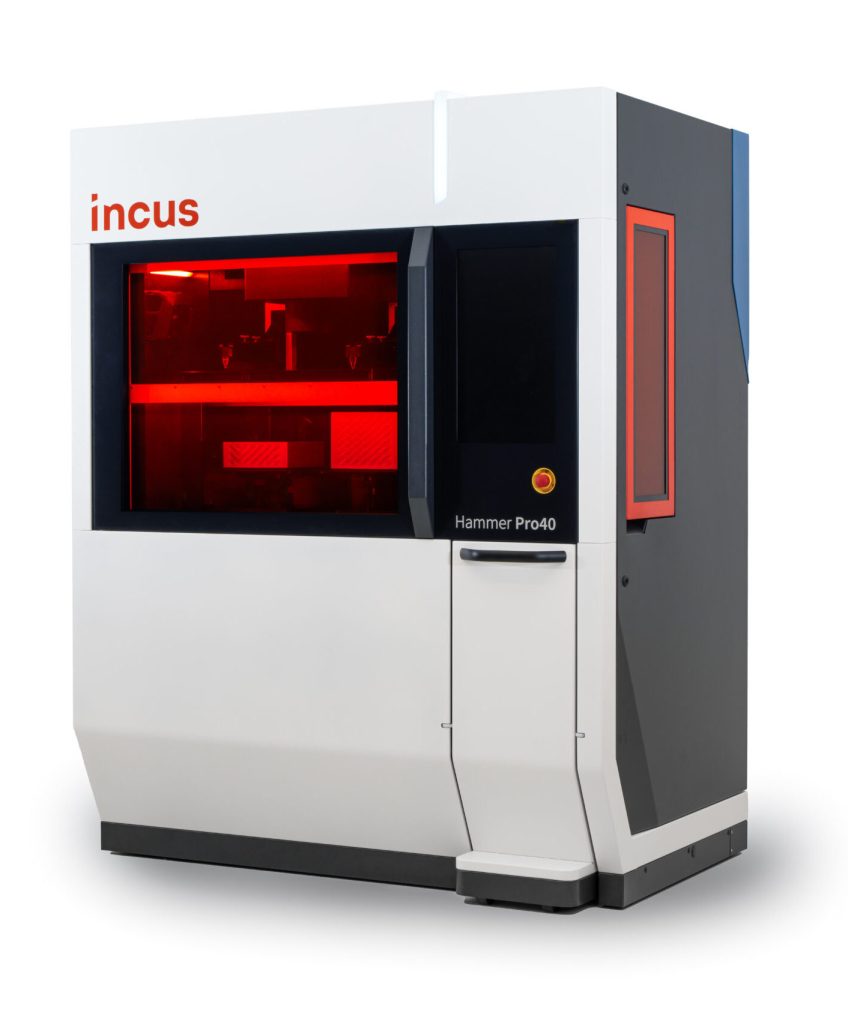

Austrian engineering firm and OEM Incus GmbH has announced the launch of its newest Lithography-based Metal Manufacturing (LMM) 3D printer, the Hammer Pro40.

Designed to meet demands in mass manufacturing, the Hammer Pro40 offers upgraded production capabilities and can be deployed directly onto the factory floor. Building on the Hammer Lab35, Incus’ newest 3D printer is advertised as offering a substantial build volume, high potential throughput, and “excellent resolution.” As such, the Hammer Pro40 can reportedly 3D print complex geometries with high-quality surface finish.

The new Incus Hammer Pro40 will be presented for the first time at Formnext 2023 in Frankfurt, between November 7-10.

“The Hammer Pro40 was strategically developed to fulfill the growing demand for mass manufacturing with AM while still delivering the unique features of our technology,” commented Incus CEO, Dr Gerald Mitteramskogler. “This innovation means a leap forward in terms of speed, precision, and cost-effectiveness, but it also opens up new opportunities to leverage the versatility of our manufacturing solution.”

“Within a single print, you can create intricate medical gripping devices, patient-specific dental brackets, personalized jewelry pieces, prototypes for electronic devices, and customized automotive knobs for luxury interior designs – all in quantities ranging from single prototypes to mass manufacturing,” added Dr Mitteramskogler.

Key features of the Hammer Pro40

According to Incus, the Hammer Pro40 has been designed to manufacture intricate, specialty parts in large batches. This new LMM 3D printer is optimized for a range of applications, including dental, medical, automotive, micro robotics, and jewelry.

To meet demands in mass manufacturing, the Hammer Pro40 boasts a 2x 200 x 76.8 x 150 mm build volume, which is six times larger than that of the Lab35. This substantial build volume is facilitated by two moving projectors, rather than the singular stationary projector found in most LMM systems.

According to Incus, this new 3D printer has been designed to combine “unmatched cost efficiency” with high-quality 3D printing. Indeed, with a 3D print speed of up to 240 layers/h and up to 700 cm3/h, the Hammer Pro40 is seven times faster than the Lab35. The Hammer Pro40 also reportedly has a cost per cm3 that is four times lower than its predecessor.

Incus’ newest 3D printer is also said to offer a pixel pitch of 40µm in X/Y, allowing for the production of high-quality end-use parts. With a surface roughness (Ra) of 2µm after sintering, the Hammer Pro40 reportedly removes the need for additional surface treatments such as polishing or sandblasting.

Automation is also said to be a key asset of the Hammer Pro40, with the 3D printer designed to operate several 3D prints without human input, including a feedstock supply that lasts up to 3 days. Job preparation, setup, and material changeover are also said to be streamlined, and take less than 5 minutes. The handling of the green parts can also be easily automated, due to their high green part strength.

Technical specifications and pricing

Incus has not yet released pricing or purchase information for the Hammer Pro40. More information will be available during Formnext 2023. The Hammer Pro40 will be located in hall 11.1, booth D42 during the Frankfurt-based show.

| 3D Printing Technology | Lithography-based Metal Manufacturing (LMM) |

| Projection System | Two scrolling projector units |

| 3D Print Volume | 2x 200 x 76.8 x 150 mm |

| Pixel Pitch | 40µm |

| Slice Thickness | 10-100µm |

| Pixel Count (X, Y) | 2x 5000 x 1920 px |

| 3D Print Speed | Up to 240 layers/h and up to 700 cm3/h |

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows the new Incus Hammer Pro40 LMM 3D printer. Image via Incus GmbH.