Time is running out! Nominate now for the 3D Printing Industry Awards 2023.

Shenzhen-based 3D printer manufacturer Bambu Lab has launched the X1E, the latest addition to its X1 FDM 3D printer series. Unlike previous X1 offerings, Bambu Lab’s newest 3D printer has been designed for professionals and engineering applications

At its core, the X1E is an upgraded X1 Carbon system with added engineering-grade features. These features include a new LAN-only mode for off-cloud operations, a heavy-duty air filtration system, active heating, and build chamber temperature regulation. The max nozzle temperature has also been increased, broadening compatibility to higher performance materials.

Key features of the Bambu Lab X1E

Enhanced connectivity is a key theme of the new X1E. For its new 3D printer, Bambu Lab has added an ethernet connection port, ensuring more robust and reliable network communication. Ethernet connectivity also allows for the X1E to be used in crowded wireless signal environments, which can be common in professional applications.

The X1E also provides WPA2-Enterprise Wi-Fi Authentication (EAP-PEAP/EAP-TLS/TAP-TTLS). Individual physical kill switches for Wi-Fi and Ethernet have also been added, allowing the X1E to meet stringent network security requirements.

Off-cloud operation has also been added to Bambu Lab’s new 3D printer. Thus, the X1E can be operated completely independently without being connected to Bambu Cloud Service, and is fully functional within the user’s local network. The X1E can also be remotely controlled through LAN, without the need for an internet connection.

A “heavy duty” air filtration system has also been added to the X1E, effectively filtering VOCs and particulates generated during 3D printing. This filtration system combines a G3 pre-filter, an H12 HEPA filter, and a high-quality coconut shell activated carbon filter. Optimized for professional and engineering applications, this filtration system is said to effectively reduce odors and particulates when 3D printing in poorly ventilated environments.

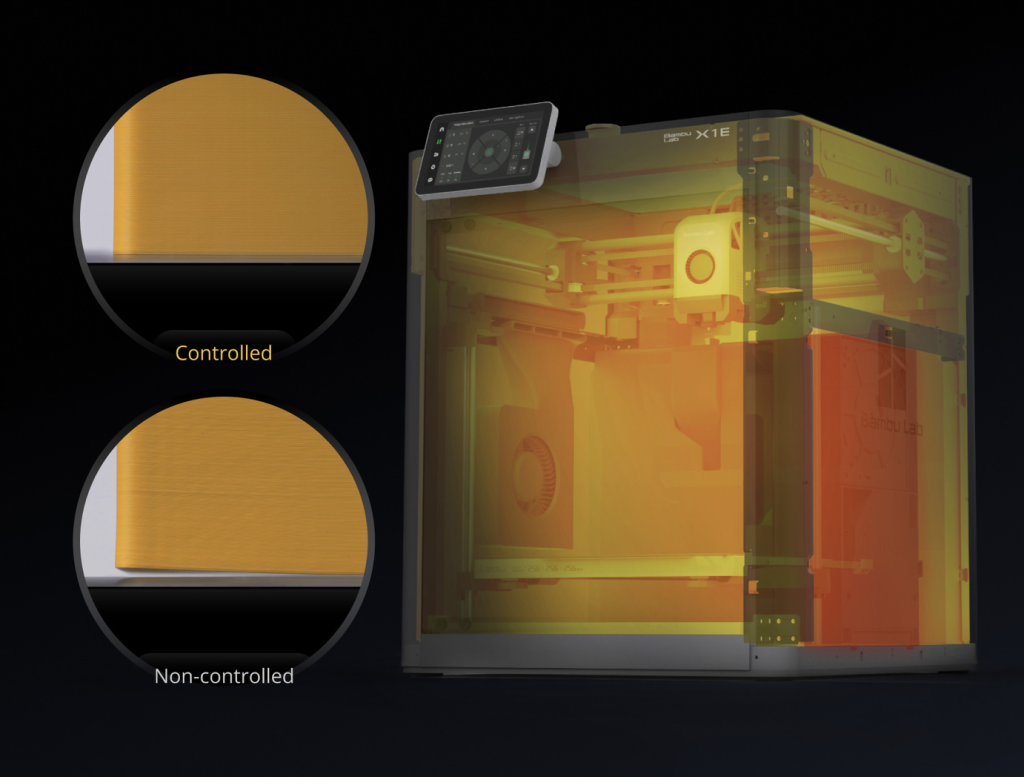

The X1E is also billed as offering improved 3D print quality. Indeed, the X1E offers active 3D print chamber heating and temperature regulation, reducing warping and improving layer bonding. The X1E actively controls 3D print chamber temperatures up to 60℃ or 140℉. This is said to improve the quality of 3D prints, especially when using materials that are prone to warping, such as ABS and PC.

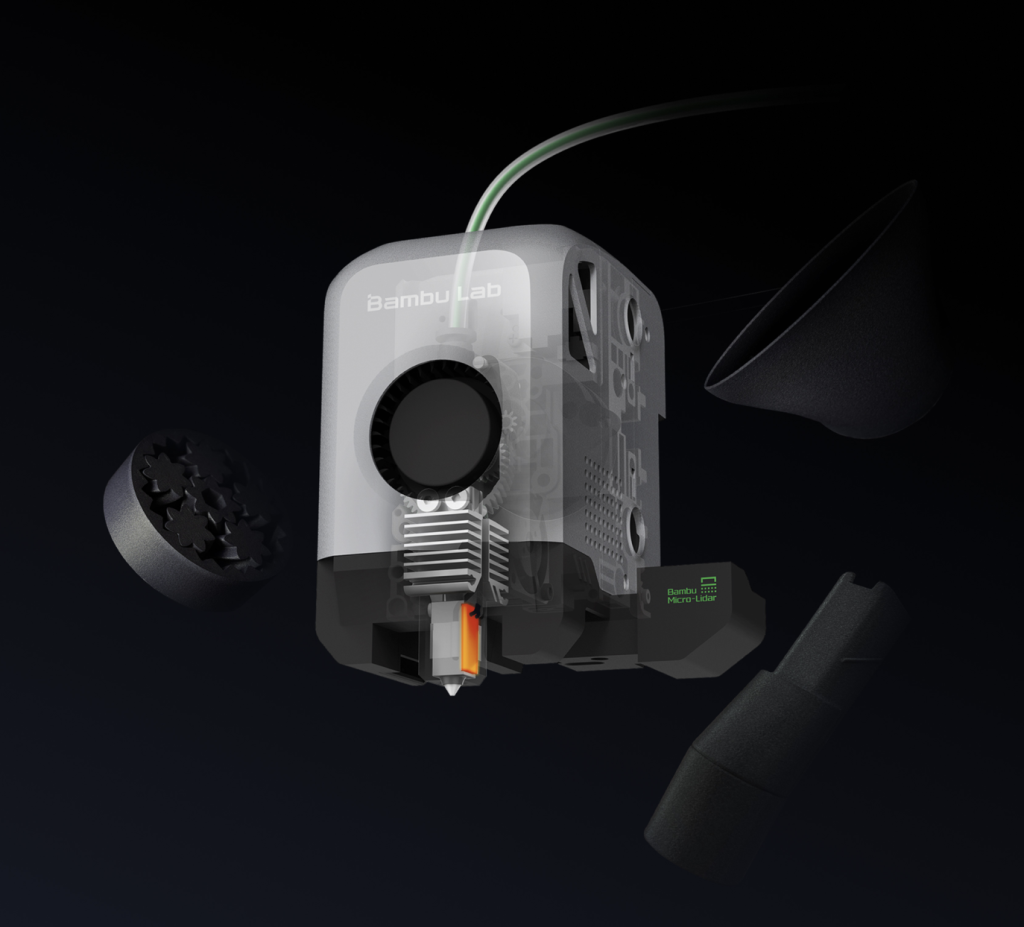

Bambu Lab’s new 3D printer also offers wide-ranging, higher-temperature material compatibility thanks to its 320℃ nozzle. This high-temperature nozzle allows the X1E to 3D print with higher-performance materials such as PPA-CF/GF PPS and PPS-CF. This makes the X1E better suited to engineering applications, with these materials offering better dimensional stability, heat resistance, and mechanical performance.

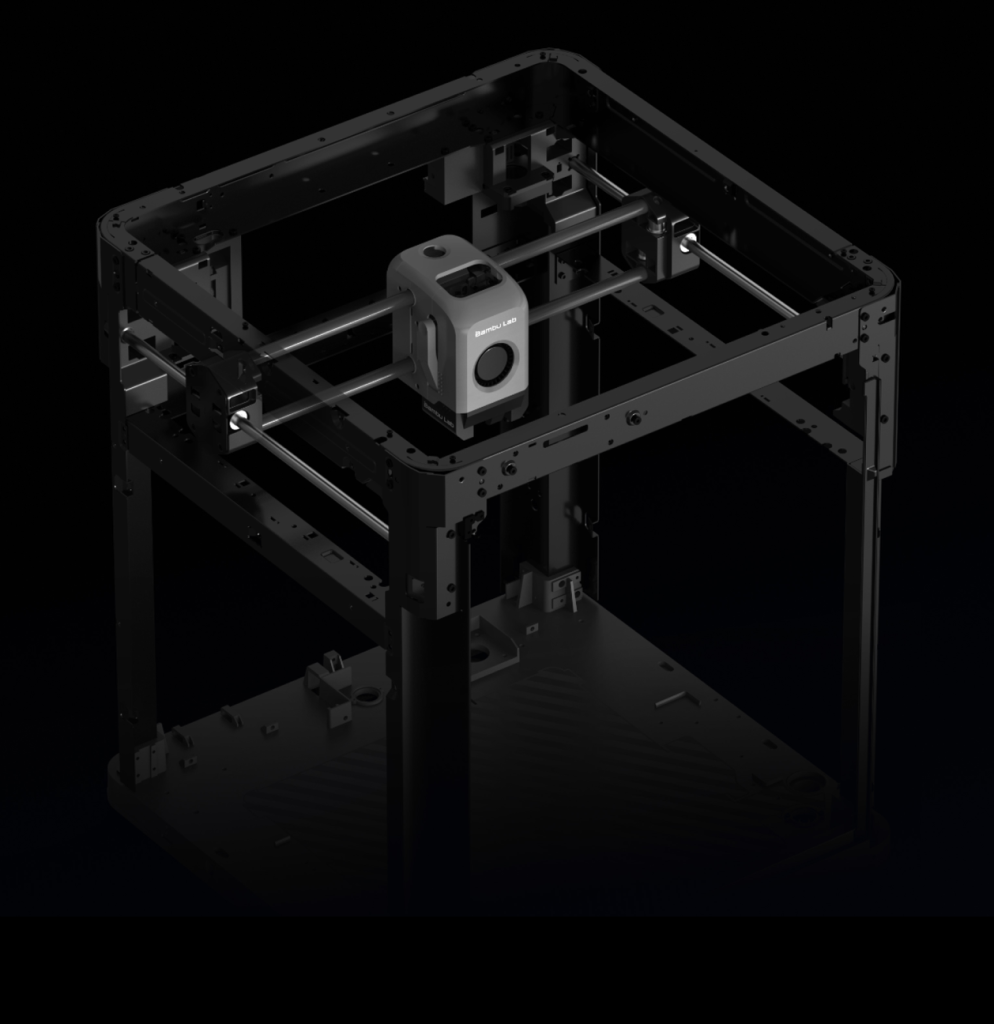

High-speed 3D printing is also enabled by the X1E’s CoreXY motion structure. Incorporating carbon-fiber rods, this structure allows the X1E to achieve tool head acceleration of 20,000 mm/s2, and maintain 500 mm/s travel speeds for longer periods.

High-3D print speeds can often result in sacrifices to 3D print quality. However, Bambu Lab claims that this is not the case for the X1E. This is because the X1E can actively compensate for XY-axis vibrations and extrusion issues, ensuring reliable 3D print quality at high-speeds. These compensation measurements are fully automatic, eliminating the need for manual adjustments.

Filament wastage and 3D printer downtime are limited by the X1E’s AI failure detection system. According to Bambu Lab, the 3D printer’s AI algorithm can detect first layer imperfections and spaghetti failures with the assistance of Lidar and visual imaging. As such, 3D prints are automatically paused to prevent catastrophic failures.

Multi-filament 3D printing is also enabled by the X1E. In fact, Bambu Lab’s new 3D printer can simultaneously connect four Bambu AMS systems to 3D print with up to 16 spools of filament. This is said to be ideal for 3D printing delicate support materials, ensuring good surface finish, and enabling multi-color 3D printing. The AMS system also supports automatic filament reload, further automating the 3D printing process.

Technical specifications and pricing

The new Bambu Lab X1E is priced at $2,499 USD (before tax), and can be purchased through the company’s official 3D printer resellers.

| Build Volume | 256*256*256 mm3 |

| Physical Dimensions | 389*389*457 mm3 |

| Net Weight | 16 kg |

| Max Speed of Toolhead | 500 mm/s |

| Max Acceleration of Toolhead | 20 m/s2 |

| Max Hot End Flow | 32 mm3/s @ABS(Model: 150*150mm single wall; Material: Bambu ABS; Temperature: 280°C) |

| Hot End material | All Metal |

| Extruder Gears | Hardened Steel |

| Nozzle material | Hardened Steel |

| Maximum Chamber Control Temperature | 60℃ |

| Maximum Hot End Temperature | 320℃ |

| Nozzle Diameter | Included: 0.4 mmOptional: 0.2 mm, 0.6 mm, 0.8 mm |

| Filament Diameter | 1.75 mm |

| Supported Filament | Optimal: PLA, PETG, TPU, PVA, BVOHSuperior: ABS, ASA, PC, PA, PETSuperior: Carbon/Glass Fiber Reinforced PLA, PETG, PA, PET, PC, ABS, ASAIdeal: PPA-CF/GF, PPS, PPS-CF/GF |

| Max Build Plate Temperature | 110℃@220V, 120℃@110V |

| Slicer | Bambu StudioSupport third party slicers which export standard G-code such as SuperSlicer, PrusaSlicer and Cura, but certain advanced features may not be supported. |

| Slicer Supported OS | MacOS, Windows |

| Ethernet Socket | RJ45 |

| Ethernet Speed | 100 Mbps / Full Duplex |

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows Bambu Lab’s new X1E 3D printer. Image via Bambu Lab.