Texas-based construction company ICON has delivered what it hails as the “world’s first” 3D printed lunar launch and landing pad to NASA, bringing its goal of creating an off-world construction system for the moon a step closer.

Working with a team of students from 10 colleges and universities across the US, ICON used its proprietary technology to 3D print a reusable landing pad using materials found on the moon. The partners recently conducted a static fire test of the rocket pad with a rocket motor at Camp Swift, a Texas Military Department location just outside of Austin.

“This is the first milestone on the journey to making off-world construction a reality, which will allow humanity to stay – not just visit the stars,” said Michael McDaniel, Head of Design at ICON.

ICON’s move into space-based 3D printing

Primarily a construction technologies company, ICON has previously used its proprietary 3D printing robotics, software, and advanced materials to build affordable homes around the world. The firm has continued to expand the applications of its technology having worked with the US Marine Corps to print vehicle hide structures at their Camp Pendleton base last year.

Most recently, ICON earned a Small Business Innovation Research (SBIR) contract from NASA to develop its technologies for use in outer space and produce a 3D printed off-world construction system for the moon. Named Project Olympus, the initiative will see ICON team up with architecture firms BIG and SEArch+ to design lunar structures that can be additively manufactured using materials available on the moon’s surface.

The project is part of NASA’s Artemis program aiming to return astronauts to the moon by 2024, and which has already used 3D printing to develop rocket engine parts and its lunar lander for the mission.

Conceiving the Lunar Plume Alleviation Device

The Lunar Plume Alleviation Device, also known as the Lunar PAD, is designed to solve challenges caused when the force of a rocket engine’s exhaust meets the dusty lunar surface.

The Lunar PAD was first proposed by the student team during a Nasa Proposal Writing and Evaluation Experience training course in 2019 run by John Dankanich, Chief Technologist at NASA’s Marshall Space Flight Center. The training course was part of the Lucy Student Pipeline Accelerator and Competency Enabler (L’SPACE) Academy, and the students won funding and support from NASA to mature their concept.

In June last year, the team presented their design to the experts at the Marshall Center and secured further funding to print and test a subscale version of the Lunar PAD.

“The proposal addressed a technology pain point, as the project enables a safe and reusable landing pad required for sustainable lunar exploration,” said Dankanich. “The team worked many hundreds of hours, engaged NASA subject matter experts, and went from concept formulation to a preliminary design. They then turned that design into reality with the subscale construction, all in a few short months.”

How does the Lunar PAD work?

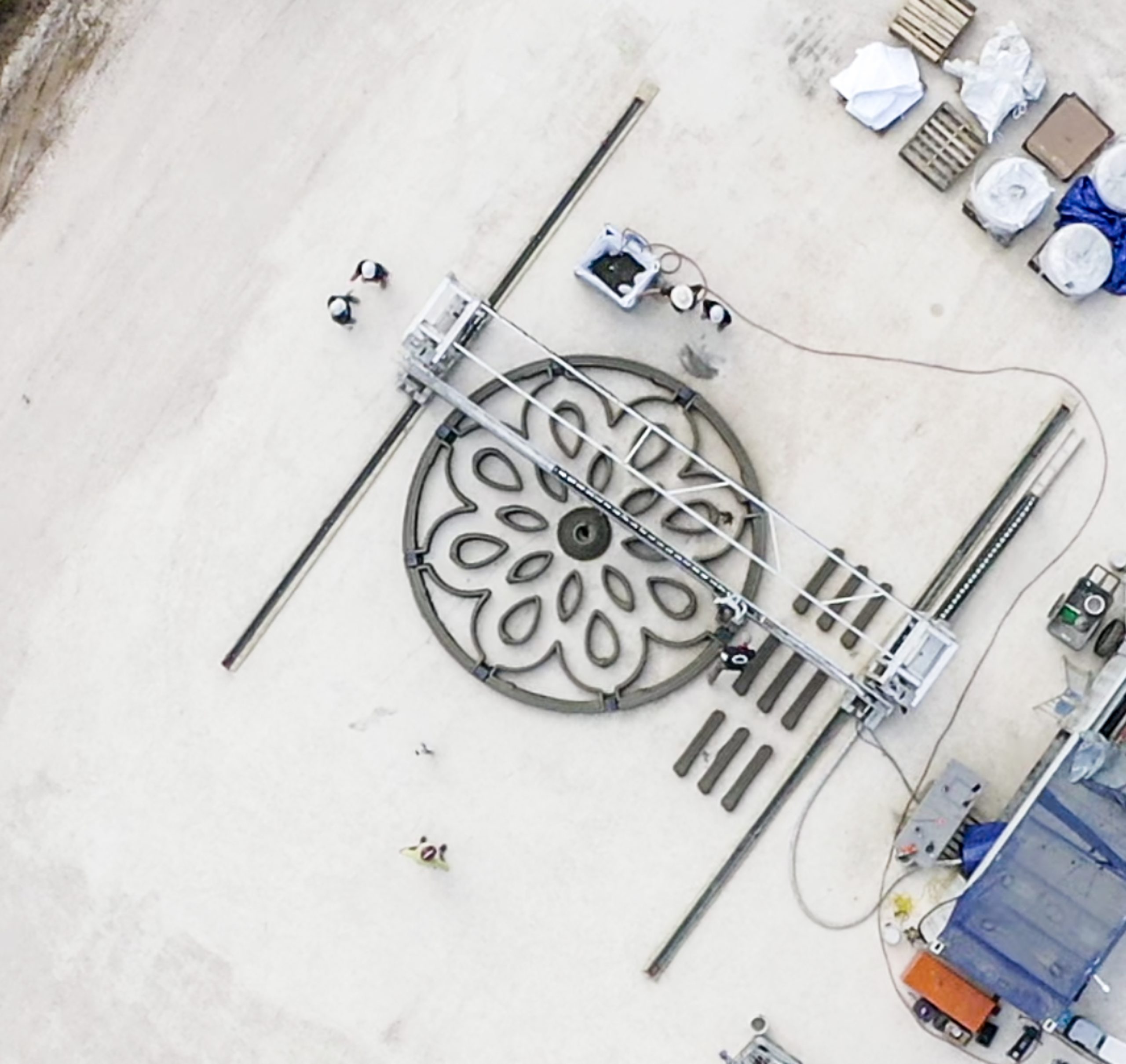

The Lunar PAD is comprised of two layers, one being the ‘roof’ where a rocket launches from and lands on, and the other a series of petal-like channels beneath this to redirect the rocket’s exhaust. The exhaust is guided into the channels through slits in the roof and is then directed to the edge of the launch pad where it is dispersed through specialized vents. The roof and weight of the rocket are supported by a central cone and dividers, which are surrounding by a wall to capture any lunar dust particles that become mobilized during launch or landing.

The student team worked with experts from NASA Marshall’s Moon-to-Mars Planetary Autonomous Construction Technologies (MMPACT) project, which aims to develop infrastructure on the moon from lunar materials including landing pads, habitats and shelters, roadways, berms, and blast shields, to test the design and its suitability for 3D printing.

The teams turned to MMPACT partner ICON to produce the subscale Lunar PAD prototype using a cement-based material and the company’s proprietary gantry-based 3D printing system. ICON printed the 20 ft x 20 inch launch pad in seven hours, with 14 hours of infill.

The teams recently completed a successful hot fire test of the launch pad at Camp Swift, with instruments to measure temperature, strain, and exhaust flow behaviour integrated into the pad during printing. According to the team, preliminary analysis showed the Lunar PAD performed true to design.

“It has been a pleasure working with these students over the last year and helping to advance the state of the art in planetary launch and landing pads,” said Mike Fiske, MMPACT Project Lead. “The results from this project contribute strongly to our future knowledge of lunar launch and landing pads and get us one step closer to lunar infrastructure.”

Andres Campbell, Principal Investigator for the Lunar PAD team, added: “While the Lunar PAD team is a very diverse group, we have always been bound together by our passion for the continued exploration of space. We are looking forward to the continued success of the Lunar PAD project with future publications and other academic or professional work.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows hot fire test of the Lunar PAD at Camp Swift. Photo via ICON.