When a Kickstarter campaign promises a 3D printer that is small, portable, high resolution and even battery operated for less than one tenth the cost of the next available system based on a comparable technology it is going to be a success. In fact, 3D printing campaigns on Kickstarter have been a success when promising much less. The iBox Nano is a tiny high-resolution resin-based 3D printer that promises great innovations in terms of pricing, portability, accessibility and technology and these do not seem to be empty promises either.

So much so that almost 1500 people have joined the campaign helping Melbourne, Florida-based iBox Printers raise well above the $300,000 goal, making it the fifth most successful 3D printing related campaign on the world’s most popular crowd-funding website with still – as I write – almost a week to go.

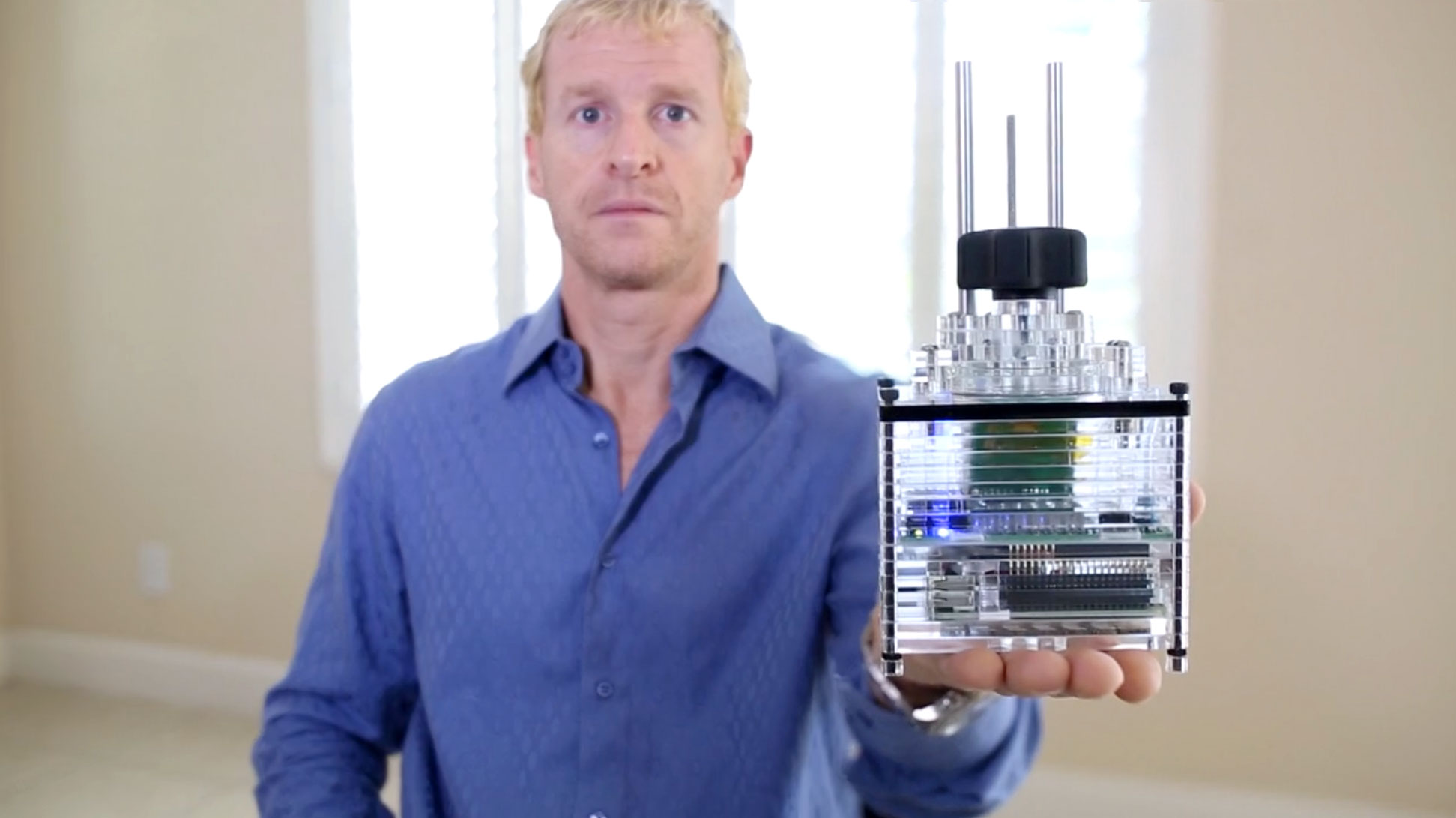

Trent Carter, iBox Printers founder, and his 20-people strong team, initiated the product’s design in February 2013 and got the first fully working Alpha unit in June 2014, with Beta units performing beyond expectations shortly thereafter. The October Kickstarter launch has been planned so as to have the Super Early Bird units shipping in time for Christmas and Early Beta Adopters units out in February, with mass production to begin in March.

They really left very little to chance, which further testifies as to the company’s credibility. And it is a good thing because the iBox Nano is being presented as a device capable of further disruption in an industry that is already disrupting traditional manufacturing. First and foremost for its price: the system will be available for an incredibly low $189 to Super Early Bird funders with the final retail price coming in at $299. This means that, although the iBox Nano is small and it has a small printing volume of 40x20x90 mm, you could theoretically purchase 10 of them for the price of the next comparable resin-based system.

Carter and his team have developed a new type of optical 3D printing technology based on LCD and UV-LED’s instead of laser or digital projection. This means that the cost of the system is considerably lower (no need to purchase a separate or internal digital projector) and also that its energy requirements are significantly limited.

The iBox Nano runs on 5 volts and has an average current consumption of 550 mA during printing. This is compared by the iBox team to the Form 1’s 1500 mA, the Ultimaker’s 4000 mA and the Replicator 2’s 6250 mA. The average power required during printing is 3 Watts. Once again it distances all competition with the Form 1 reported at 60 Watts, and the Ultimaker and Replicator well beyond 100 Watts.

This makes it possible for the iNano to effectively run on a notebook PC’s energy or even on batteries, the very first 3D printer to ever do so. iBox Printers offers optional 10 and 20 hour battery packs which connect to the Nano via USB. These will be available for purchase in January 2015 and, coupled with its record low weight of only 3 lbs (about 1.5 Kg), will make it the most portable 3D printing system available.

On top of these truly innovative features, the iBox team has been going to great lengths to ensure that their little giant offers the best possible features in terms of actual 3D printing and accessibility. The iBox Nano is effectively a computer running on a Raspberry Pi, which means you could connect a 4K monitor to it via its HDMI port. It also connects via Wi-Fi to any device and offers direct, browser-based 3D printing through its proprietary software and network.

Since it has been created to make small objects, it can push the limits in terms of Z axis resolution, with the potential to go as high (or as low) as 0.39 micron. At this resolution each print might take a very long time but you can just let the printer do its job as its technology allows it to be completely silent, even more so than the SLA based Form 1 (iBox says its noise level is 29 db, compared to Formlab’s 54 db).

It has been constructed using laser cut Poly(methyl methacrylate), aka PMMA, which makes it almost entirely see-through and aesthetically pleasing to the eye. iBox Printers is betting that people will mostly want to create small high resolution objects, such as miniatures for strategy games or small gadgets. At $299, with compatibility for easily available low cost color resins such as those from Makerjuice (in green, red, blue, yellow and white), the best game might be the 3D printing itself.