French construction firm Vinci has made a financial investment in UK-based tunneling company hyperTunnel.

With Aquaa Partners serving as the exclusive financial adviser to hyperTunnel for the deal, the undisclosed amount will be used to further advance and test the company’s novel tunneling technology, which relies on 3D printing, AI, and swarm robotics.

The move also strengthens hyperTunnel’s existing connection to Vinci’s technical departments. hyperTunnel recently became a part of Vinci’s ‘Leonard’ innovation platform after joining Catalyst, the latter’s startup accelerator program. The company also won the annual Construction Start-up Competition held in Miami last year, which Leonard co-organizes along with construction industry players Ferrovial and Cemex Ventures.

Jeremy Hammond, co-founder of hyperTunnel, said, “VINCI and Leonard are real experts when it comes to construction innovation, so to get their backing in such a concrete and substantial way means we must be doing something right. They can see the huge potential of the technologies we’re developing, and they share our passion for improving how the world works. We’re excited to see what we can achieve together over the coming months.”

How does hyperTunnel’s technology work?

Founded in 2018 in Basingstoke, hyperTunnel has 40 employees across its headquarters, outdoor learning environment, and its Geolab in the North Hampshire Downs. Currently in the scale-up stage, the firm’s tunneling technology is designed to enable underground infrastructure in a faster, cheaper, safer, and more environmentally-friendly manner than current processes.

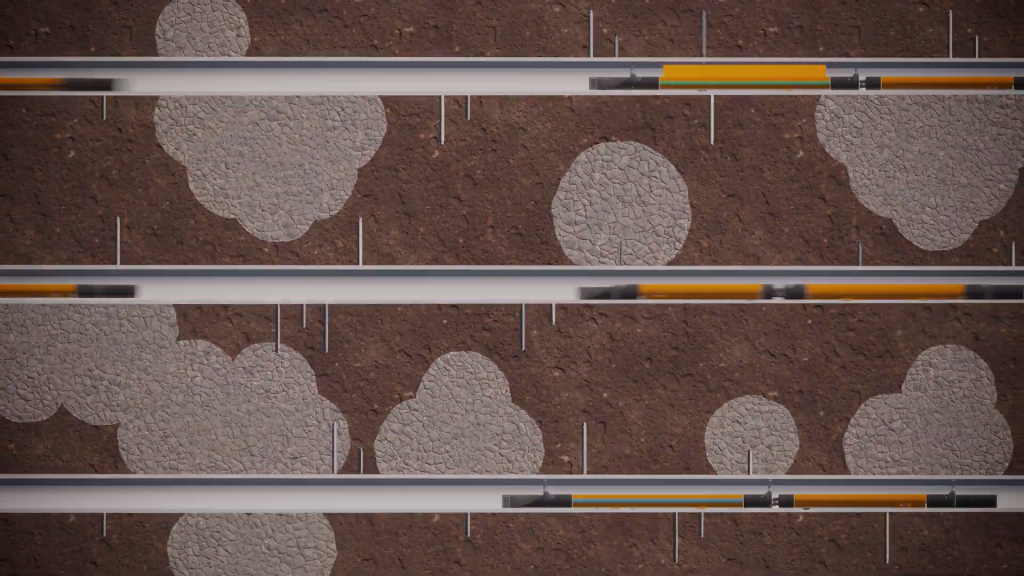

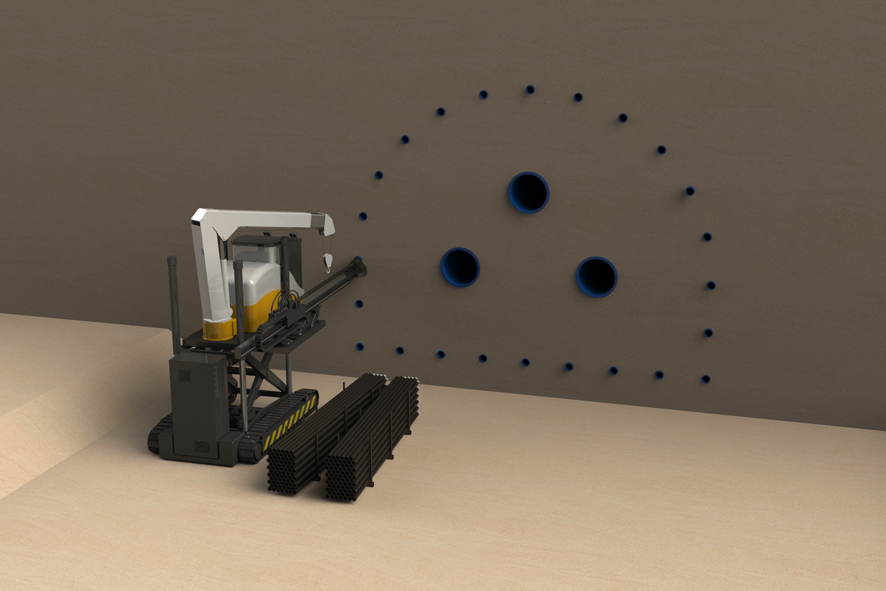

To start off, the firm sets up a compact worksite and drills a central index bore using horizontal drilling machines. They then drill bores to define the shape of the tunnel around the central index and send in geological survey tools to gather data for a digital twin of the tunnel.

By mapping a detailed blueprint of the structure, hyperTunnel is able to send in hundreds of its autonomous cylindrical AI-powered swarm robots to carry out various tasks. These tasks include surveying, drilling and installing access points, CNC machining chambers into the surrounding soil, and filling these chambers with high-strength construction materials. The company fills and stacks several of these modular chambers next to each other to ‘3D print’ the wider tunnel structure block by block. This is all performed by the swarm robots directly in the ground.

Once the structure is printed, hyperTunnel disrupts the surrounding soil and clears the debris using its self-driving trucks, leaving behind the concrete 3D printed tunnel.

“hyperTunnel’s technology can be truly game-changing when it comes to improving the safety and sustainability of underground construction projects,” said Guillaume Bazouin, Head of Start-up and Intrapreneurs programs at Leonard. “It strongly aligns with our goals of rapidly responding to the climate emergency by enabling technological advances that have a substantial environmental impact. hyperTunnel also boasts exceptional leadership and engineering teams, and we are looking to support their great success in the near future.”

Making waves in the construction sector

Vinci isn’t the only organization to see hyperTunnel’s potential either. Just recently, the European Innovation Council (EIC) awarded the firm €1.88 million in funding as part of its EIC Accelerator program. Much like the Vinci investment, the capital will be used to further develop and test the swarm robotics technology before industrial deployment.

Back in 2021, hyperTunnel also announced the signing of a contract with the UK’s Network Rail. The company was also selected by the Innovate UK agency to join its Global Business Innovation Programme.

David Castlo, Network Technical Head at Network Rail, adds, “Our large portfolio of Victorian tunnels requires increasing levels of work to meet the needs of the railway network. However, we want to reduce disruption to our passengers so we are constantly searching for new approaches to enlarging or re-lining tunnels that reduce the length of time a tunnel will be closed to trains.”

hyperTunnel is one of many players in the construction 3D printing game. Over in the US state of Virginia, Alquist 3D recently announced plans to 3D print 200 new homes. The company finished building the ‘first owner-occupied 3D printed home’ earlier this year, having now detailed plans to carry out the largest construction project realized with the technology to date, across-state in Pulaski and Roanoke.

Elsewhere, in Tibet, China announced a new project to 3D print a hydroelectric dam in just two years with the help of AI technology. The 180-meter dam will reportedly be constructed entirely by AI-powered robots working in tandem to act as a giant 3D printer.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows François Pogu, Managing Director at VINCI Construction Grands Projects and Steve Jordan, co-founder of hyperTunnel. Photo via hyperTunnel.