Engineers in both the US and Russia are seeking out new ways to improve the properties of the concrete walls in 3D printed homes, it has been announced.

At Peter the Great St. Petersburg Polytechnic University, researchers have paired thermal imaging with modeling to identify the ideal configuration for 3D printing walls, capable of high levels of heat retention. The US Department of Energy (DOE), meanwhile, is backing several similar projects with a $39 million grant, one of which is set to see the 3D printing of a carbon-absorbing floor from bio-materials.

“There’s huge, untapped potential in reimagining building materials and construction techniques as carbon sinks that support a cleaner atmosphere and advance President Biden’s national climate goals,” said US Secretary of Energy, Jennifer M. Granholm. “This is a unique opportunity for researchers to advance clean energy materials to tackle one of the hardest to decarbonize sectors that is responsible for roughly 10% of total annual emissions in the United States.”

Investing in decarbonization

Awarded as part of the Harnessing Emissions into Structures Taking Inputs from the Atmosphere or ‘HESTIA’ program, the DOE’s grants are designed to support the R&D being conducted into technologies capable of overcoming the barriers associated with carbon-storing buildings, especially around costly/scarce building materials.

According to the DOE itself, most of the greenhouse gas emissions associated with the construction, renovation and disposal of buildings are “concentrated at the start of their lifetime.” As such, identifying novel, net carbon-negative materials and structural designs is considered essential to addressing the world’s increasingly urgent environmental challenges.

With this in mind, the DOE’s Advanced Research Projects Agency-Energy (ARPA-E) agency has selected 18 projects to receive a share of its latest funding round. Of these initiatives, two have now set out plans to make 3D printing central to their work, with one being conducted at Texas A&M University and the other at the University of Pennsylvania.

In the case of the former, researchers are not only developing net-carbon-negative building designs, but a ‘hempcrete’ 3D printing material, composed of the hemp plant’s woody core mixed with a lime-based binder. Once ready, it’s believed the team’s approach will enable the faster construction of lower cost buildings, which are more resilient to natural hazards than those built from light wooden framing.

At the University of Pennsylvania, on the other hand, engineers are working on a prefab funicular floor that’s designed to be lightweight, but feature a maximized surface area for carbon absorption. The structure is set to be built using a novel carbon-absorbing concrete, as well as additional bio-based carbon-storing materials, in a method that’s meant to complement timber-based approaches.

Although no date has been set for their conclusion, a full breakdown of all 18 HESTIA projects that have gained ARPA-E funding has been published via the DOE.

Energy-efficient 3D printed walls?

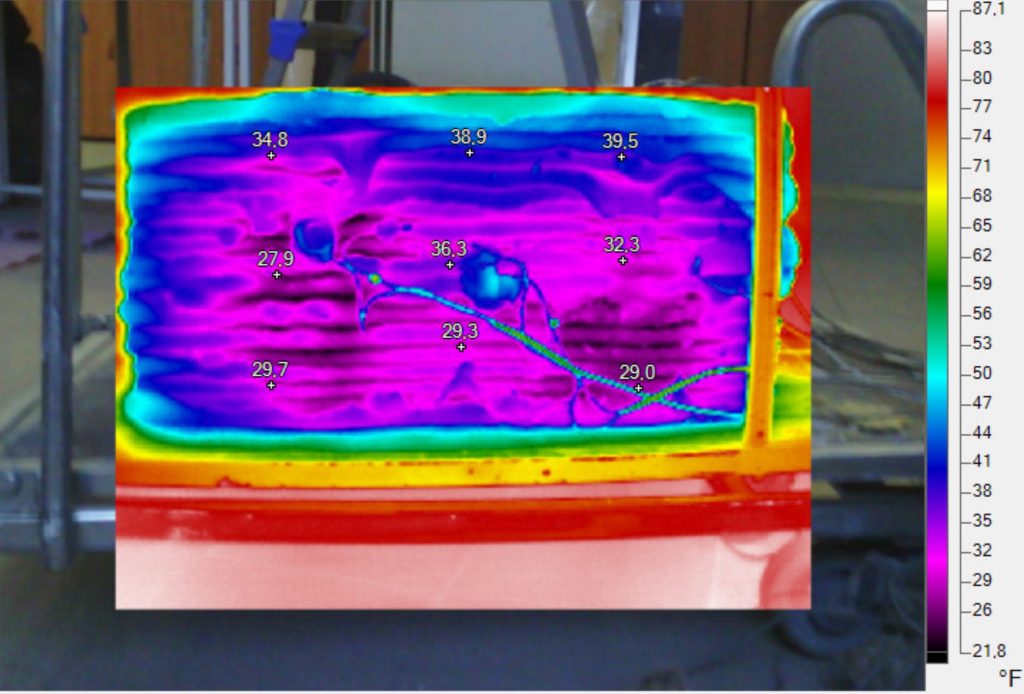

While these US DOE-backed projects get underway, researchers in Russia have already made a breakthrough in their efforts to understand the relationship between geometry, and the thermal properties of 3D printed walls. According to the St Petersburg-based team, 3D printing is currently “opening up a wide range of possibilities” for architects, but the fire safety of resulting structures is unclear.

In order to ascertain the energy efficiency and heat transfer properties of enclosed 3D printed structures, the engineers have therefore simulated the impact that geometry has on each of these aspects. To achieve this, the team developed a series of prototype walls, with differently-shaped triangular and rectangular interior designs, as well as varying materials and levels of stone wool insulation.

Once ready, these test specimens were then fitted with sensors and subjected to heat and mass transfer simulations. Following subsequent numerical modeling, the researchers found that the rectangular cavities integrated into their 3D printed walls, were much more effective at stabilizing temperature than their small rectangle-shaped counterparts.

Interestingly, the team also discovered that heat flux through the air parts of their walls was significantly lower than in solid areas, thus via configuration changes alone, they were able to increase the heat resistance of resulting structures.

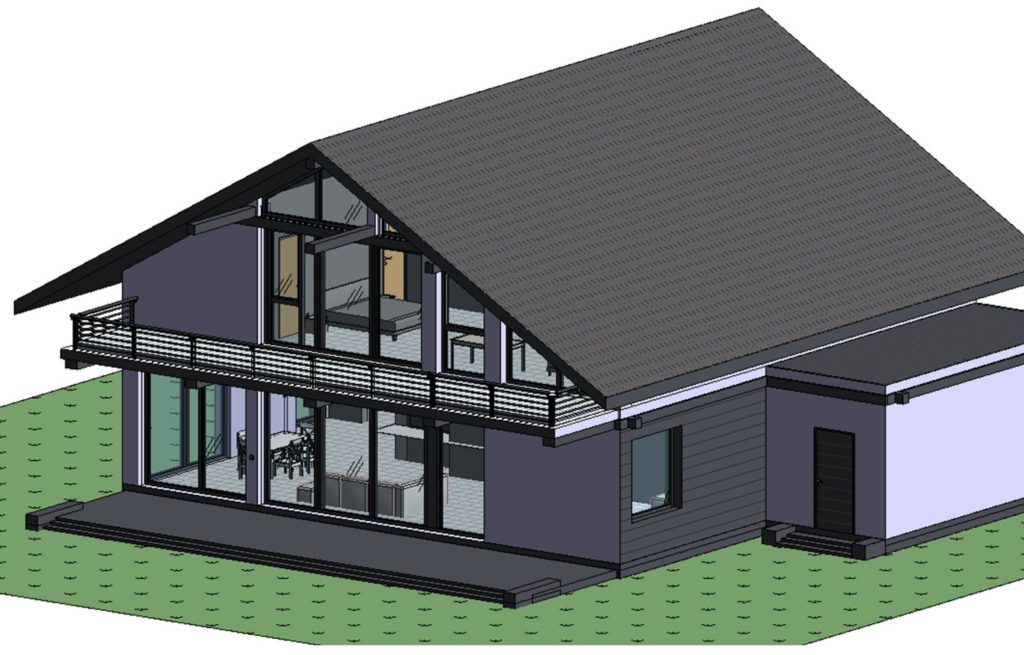

If their walls were to be deployed in practice as part of a fully-realized 3D printed home, the researchers estimate that this could be powered by as little as 3,026kW of electricity, less than the 6,312 kW used by the average Russian. That being said, the team’s prototypes did feature surface irregularities, so they accept that further research is still needed to fully-grasp their thermophysical properties.

Optimizing construction 3D printing

With construction 3D printing projects increasingly garnering global attention, a significant amount of research is now being poured into the resilience of resulting builds. Last year, researchers at University of Sri Jayewardenepura and British Northumbria University also investigated the fire safety of 3D printed walls, finding that wall density is one of the key parameters in averting incendiary outbreaks.

Engineers at the Nanyang Technological University, meanwhile, have developed a 3D printing concrete with recycled glass, which features less natural sand than conventional construction materials. With sand becoming increasingly rare due to urbanization and high levels of infrastructure development, it’s thought the feedstock could represent a novel, eco-friendly solution to this problem.

Elsewhere, on a more commercial level, construction 3D printer manufacturer COBOD has worked with CEMEX to come up with a new type of concrete that ‘gains shape instantaneously.’ Working together, the firms have already deployed this D.fab admixture-boosted blend to build Angola’s first 3D printed home.

The researchers’ findings are detailed in their paper titled “Experimental Study on the Thermal Performance of 3D-Printed Enclosing Structures.” The study was co-authored by Darya Nemova, Evgeny Kotov, Darya Andreeva, Svyatoslav Khorobrov, Vyacheslav Olshevskiy, Irina Vasileva ,Daria Zaborova and Tatiana Musorina.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a sign shaped like the ARPA-E logo alongside the US flag. Photo via ARPA-E.