The HP Metal Jet 3D printer has been launched by HP at the 2022 International Manufacturing Technology Show (IMTS). 3D Printing Industry is in Chicago this week for the show.

HP’s efforts to expand into metal 3D printing began to take shape in 2017 when plans for a high-volume jetting system were unveiled at its Security Analyst Meeting. As identified by 3D Printing Industry in 2017, HP’s metal 3D printer was expected to use Metal Injection Molding powder. HP would confirm this a year later.

Announced in 2018, HP’s much-anticipated Metal Jet technology is designed to work with Metal Injection Molding (MIM) materials rather than the spherical powders used in laser sintering metal additive manufacturing systems. According to the Global Head of the firm’s 3D Printing Metals business, Ramon Pastor, this is “a big deal,” as it enables users “to drive down cost-per-part” by 20% to 33%.

The Metal Jet S100 will launch with stainless steel 316L and 17-4PH compatibility. Pastor says that its efficiency improves its ergonomics in a way that allows it “to drive scale,” and HP “sees huge opportunities” for the system to address clients in the industrial, medical, consumer, and automotive industries.

HP’s Metal Jet 3D printing journey

Since unveiling its MJF concept back in 2014, HP has built a 3D printing offering in polymer-based machines and materials. In that time, HP systems have 3D printed over 130 million parts, and MJF continues to address the needs of firms across sectors, with the likes of Toyota now 3D printing automotive spares via the technology and Ocado 3D printing fulfillment bots.

Desktop Metal, Markforged, and Digital Metal have all launched their MIM powder-based machines. With a longer history and broader customer base, metal injection molding powders are currently cheaper than the metal powders required for additive manufacturing processes such as Direct Metal Laser Sintering (DMLS) or Electron Beam Melting (EBM). However, it has often been pointed out that material cost is not the only challenge when it comes to scaling metal 3D printing; repeatability/reliability, cycle time, post-processing, and capital investment are just some of the other considerations. Potential customers will no doubt be happy to pay less for materials.

Speaking ahead of the Metal Jet S100’s launch, Pastor described the platform as the “first introduced that is prepared to economically bring parts at scale.” HP’s metal 3D printing boss added that the system has been built with a “focus on total cost of ownership,” in a way that ensures “the variable cost of a part is the point at which users can scale production.”

Launching the Metal Jet S100

So, how does HP’s first Metal Jet 3D printer work? As the company has now revealed, the Metal Jet S100 comes fitted with a 430 x 309 x 200 mm powder bed onto which droplets of material are jetted by six HP Thermal Inkjet printheads attached to two print bars, equipped with a total of 63,360 nozzles.

Using these printheads, the system is capable of precisely placing up to 630 million nanogram-sized drops of liquid binder per second layer-by-layer to form parts with a resolution of 1,200 dots per inch (dpi).

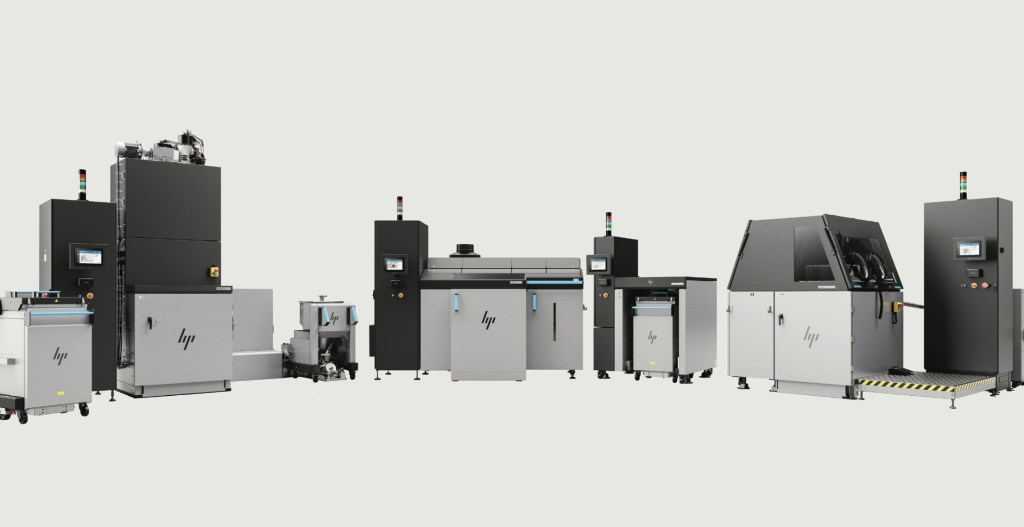

In practice, the Metal Jet S100 is designed to be modular, so more than one can be installed to create a continuous production line as part of a four-step process. After print preparation and manufacturing via HP’s powder management station, users can then debind parts using its curing station before removing any excess powder with any third-party system of their choosing.

To help realize the potential of this automated process, HP has begun working with partners GKN, Parmatech, Cobra Golf, the Legor Group, and Volkswagen. User-wise, the technology has also been adopted by initial clients like Domin Digital Motion, Lumenium, and Schneider Electric, the latter of which has already harnessed it to optimize the production of industrial metal air filters.

“This metal air filter is used in circuit breakers for when you have an inspected electric arc, and you need this not to affect the rest of the installation,” explained Pastor. “Usually, these filters are made through traditional measures, and it’s very, very expensive. We’ve been able to cut the time to produce it, and make weight reduction improvements, as they’re now 20% more compact.”

Speculators have argued that the massive gap between announcement in 2017, and launch in 2022 of the HP Metal Jet was a deliberate tactic. The announcement giving pause to potential customers who might defer their capital investments knowing an HP metal 3D printer was on the horizon. Will the success of HP’s efforts with Multi Jet Fusion translate into similar results in the metal 3D printing space?

Furthermore, it is noteworthy that the number of additive manufacturing companies producing MIM-based 3D printing systems is relatively small – with an element of cross-pollination.

Technical specifications and pricing

Below are the technical specifications for the HP Metal Jet S100 3D printer. Debuted at IMTS 2022, the system is available to order now in the US, Western Europe and China, and is expected to be made widely available by H1 2023. Pricing information has been requested from HP and the article will be updated.

| Technology | HP Metal Jet |

| Build Platform Volume | 430 x 309 x 200 mm |

| Effective Build Volume* | 430 x 309 x 140 mm |

| Build Speed | 1,990 cc/hr8 |

| Layer Thickness | 35 – 140 μm |

| Print resolution (X,Y) | 1,200 dpi |

| Printhead system | 6 Thermal Inkjet Printheads (63,360 nozzles) |

| Dimensions | 2,975 x 1,350 x 2,410 mm |

| Weight | 851kg |

*HP states Build Platform Volume meets MPIF standards for stainless steel with HP Metal Jet SS 316L and 17-4PH materials.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a facility fitted with Metal Jet S100 3D printers. Photo via HP.