The nominations for the 2021 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Tell us now before this week’s deadline.

Silicon Valley-based metal additive manufacturing firm Holo has announced the launch of its new PureForm MicroAM 3D printing platform.

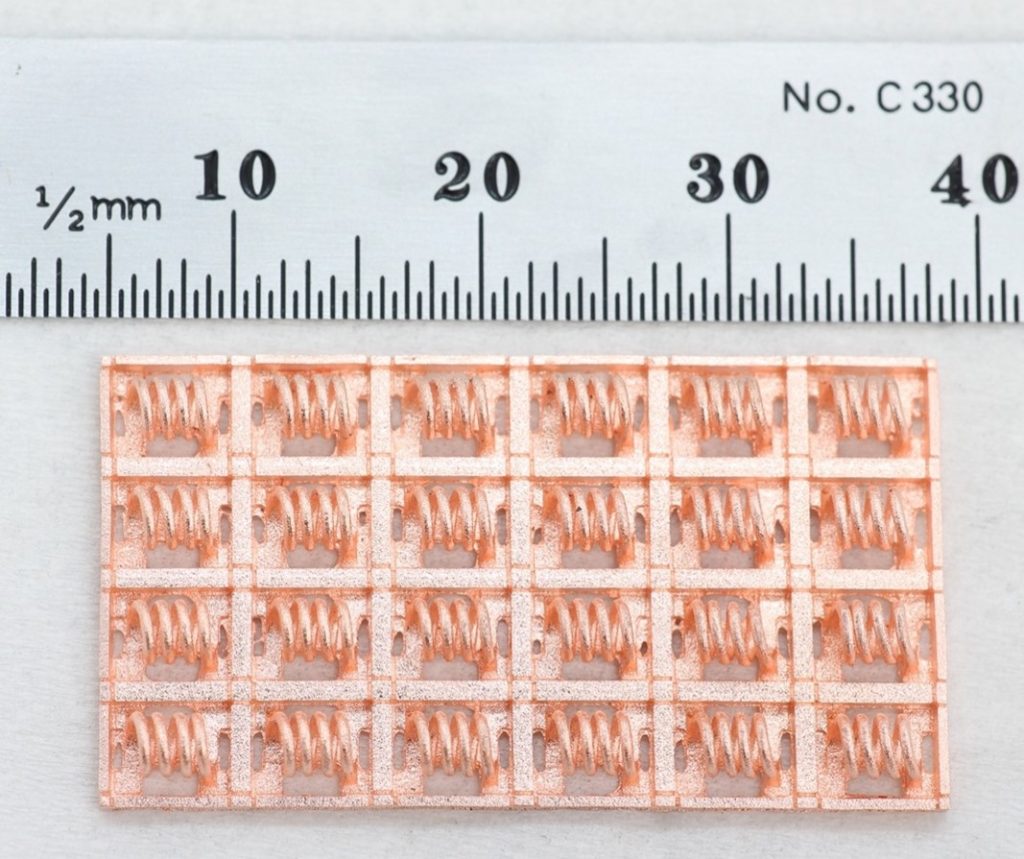

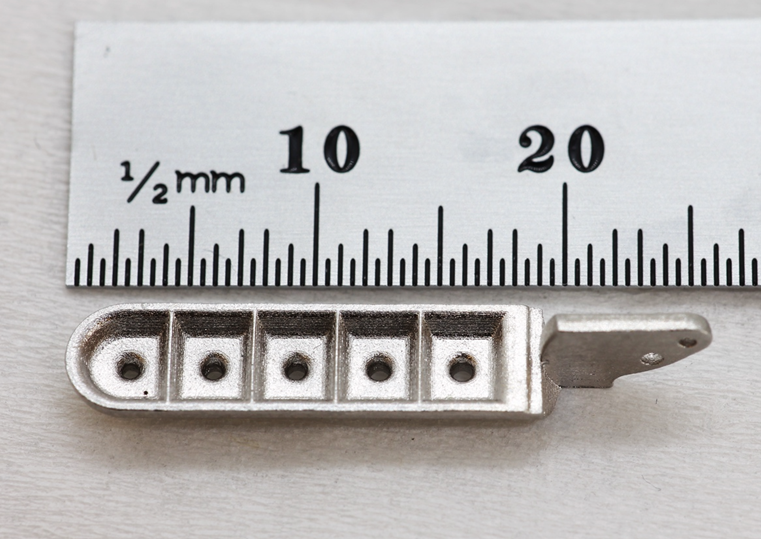

The ultra-high-precision metal 3D printing system is designed specifically for production-scale manufacturing with materials such as copper, stainless steel, and more. With the ability to 3D print features finer than 50μm, PureForm MicroAM is intended to enable a wide range of applications, including electrical components, jewelry, and medical and dental devices.

The news comes as Holo also completes its latest round of Series B funding, enlisting two new investors in the process: Lam Capital, Lam Research’s venture capital arm, and Atreides Management. Although the capital raised has not been disclosed, the round also included contributions from some of the company’s existing investors, including Prelude Ventures, Tao Capital Partners, and Lightspeed Venture Partners.

“Traditional manufacturing approaches, such as Swiss CNC, molding and casting are either too costly for volume production or cannot produce complex parts with such fine features,” said Hal Zarem, CEO of Holo. “PureForm™ MicroAM enables our customers to access parts at a lower cost and produce geometries that cannot be made any other way.”

PureForm MicroAM

Founded in 2017 as a spin-out from engineering software developer Autodesk, Holo currently holds 16 patents for its 3D printing technology and materials, with a further 27 patents pending. In March 2021, the company launched its debut PureForm additive manufacturing platform, which operates on a proprietary lithography-based process. The system cures a metal-polymer slurry from the company’s PureForm materials portfolio into a green part, which is then debound and sintered to achieve a final fully dense metal part.

Based on the same technology, the new PureForm MicroAM platform scales everything down, enabling users to 3D print micro inductor coils with 400µm strands, custom metal jewelry, and even stainless steel biopsy scoops with sharp points down to 20µm. The system is already in use at Holo’s 20,000 sq. ft. manufacturing facility in San Fransisco, where production capacity is at tens of thousands of metal parts per month.

Arian Aghababaie, co-founder and chief strategy officer of Holo, adds, “We are excited to continue to offer new capabilities to our customers, enabling us to support a host of new MicroAM applications from surgical equipment and dental, to micro-electronics, micro-robotics, consumer electronics, and jewelry.”

The Series B investment round

With the closing of the recent Series B round, Holo has expressed plans to ‘grow aggressively’ throughout 2021 and 2022. The company plans to double its employee count to further increase the throughput potential of its facilities, all while expanding on its materials portfolio.

“We believe Holo’s approach to metal additive manufacturing has great potential,” said Faran Nouri, Managing Director of Lam Capital. “Additive manufacturing is an important part of our development and innovation strategy and this funding aligns with Lam Capital’s mission to invest in forward-thinking companies that can help address today’s most challenging problems.”

The month of August has yielded several funding stories in the 3D printing industry. Robotics start-up Diamond Age recently raised $8 million in seed funding to advance its robotics technology. The company eventually aims to build a suite of 26 end-of-arm robotic tools featuring additive manufacturing technology capable of offsetting more than half of the manual labor required to build a new home. Equipped with the new funds, the firm will scale its current robotics platform and build a demonstration house spanning 1,100 square feet.

Elsewhere, digital manufacturing service provider Zetwerk recently became India’s latest business unicorn after it raised $150 million. The firm’s total value now stands at $1.33 billion.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows micro inductor coils 3D printed in a 24-piece array. Photo via Holo.