According to STEM Learning, a UK provider of STEM careers support, STEM roles are expected to double in next 10 years. Yet, the organization predicts there will be a shortfall of 173,000 skilled workers, with 89% of STEM businesses struggling to recruit. To combat this, UK education systems are incorporating more STEM teaching into their curriculum, and 3D printing is a part of this plan.

This need for more STEM help in education is the driver behind events like the annual BETT Show (British Educational Training and Technology), which recently held its 2019 edition in London, UK.

At last year’s BETT Show, 3D Printing Industry spoke to a civil servant from the UK Department for Education, who told us that the British government’s stance was to let schools incorporate 3D printing technology by themselves, rather than issuing direct guidelines on 3D printing in the curriculum.

To see how this choice has affected schools, we returned for BETT 2019, and visited the various manufacturers and services addressing 3D printing in education. We asked them about the future of 3D printing in schools, particularly, the keenness of teachers in incorporating the technology into their classrooms.

Teacher engagement with 3D printing

PrintLab, a UK provider of 3D printing curriculum, showcased its lesson plans and 3D printed models at BETT. Using these lesson plans, students can learn how to build educational objects ranging from simple, functioning percussion instruments, to “zero waste bottles” which teach children about the circular economy. The curriculum was expanded last September, and includes projects to help the differently abled, such as 3D printed braille blocks.

From Nick Mayer, co-founder of PrintLab, I learned that the company frequently liaises with 10-15 “teacher ambassadors” for advice and feedback on its curriculum. The teachers test every lesson, using their experience of the classroom environment. Through these sessions, Mayer said he felt that teachers generally are positive about the benefit of 3D printing in education, but need help adapting to it.

“I think teachers need a lot of guidance. And there’s a constant time constraint,” Mayer adds.

Despite difficulties adapting to the technology, teachers are keen to learn more about 3D printing:

“In my experience teachers are very receptive to 3D printing, especially when they see what students can do, how empowered they can be.”

BOX, a UK electronics company, provides 3D printers to selected primary schools who register their interest. The company also provides ongoing support, which Michael Hunt, 3D printing expert at BOX, feels is vital to making sure that 3D printing is supported by educators.

“If you dump a printer on them and it doesn’t work, they won’t be interested,” Hunt said. Often, he adds, teachers were put off by teething problems with the 3D printers, such as being unable to immediately understand how to operate them. However, when 3D printing is used well, students are “over the moon” to see their own designs printed.

Hunt used the example of a school that 3D printed replicas of artifacts from the Iron Age as well as Viking paraphernalia. Parents came into see the models, interested to see what had motivated their children to start talking about Iron Age artifacts at home.

“You have to find a teacher that really gets it, and can show what the machine is capable of, not just how it works.”

BOX’s range includes 3D printers from Dremel, an Illinois manufacturer of power tools. Dremel DigiLab, the educational division of Dremel, also had its own presence at BETT 2019, showcasing its recently launched 3D40 FLEX 3D printer for primary and secondary school classrooms.

In terms of teacher engagement with 3D printing, Nick Longford, Business Development Manager at Dremel, said that Europe is “behind the curve” compared to Australia, which is “at the forefront of STEM”. Longford felt that this would be a “huge year” for Australia in 3D printing education, but that European schools have been slow to adopt 3D printing technologies in their education systems. However, Longford is optimistic for the future.

“The kids want it – I think we’re at the bottom of the peak,” Longford said.

“3D printing is being used more and more to make cars, and even houses. If students aren’t learning 3D printing, they’ll miss out on what’s happening in all these industries.”

Classroom competitions and projects

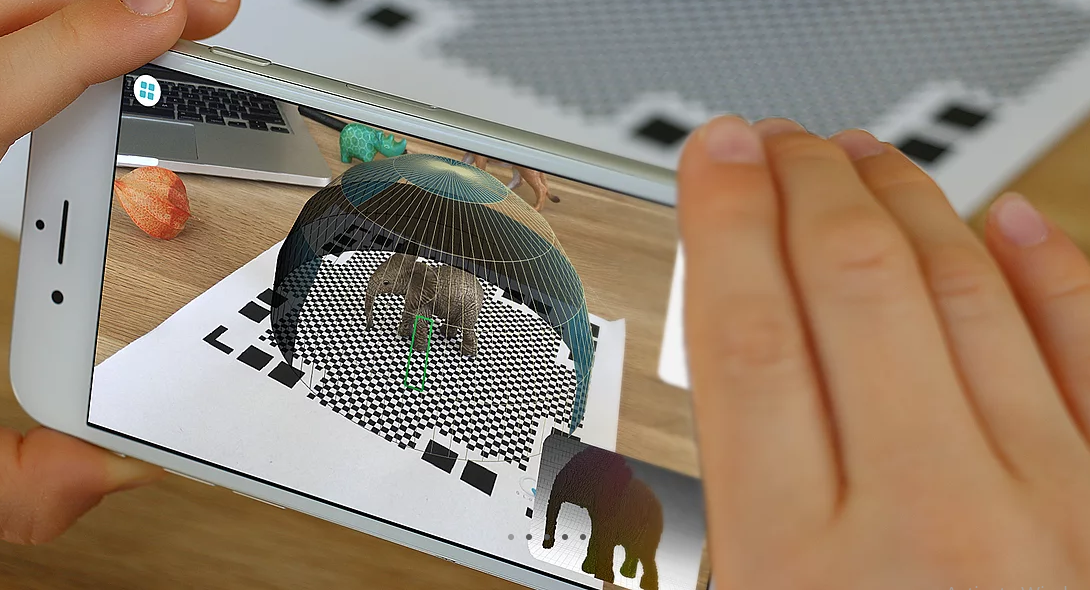

One way to get educators more interested in 3D printing is to make sure each student is as occupied as possible during 3D printing projects. Easy-to-use mobile apps are an inexpensive method of giving each child a role. For example, the Qlone 3D scanner, created by EyeCue, an AR and VR technology company from Israel.

The Qlone app is available for download to iPhone and iPad owners. Apart from these devices, the only other piece of equipment required is a paper base, which can be produced on a regular 2D printer. This base lets the program differentiate the object from its background, and correctly determine its dimensions.

To recreate the underside of the object, the user can scan this separately, then merge the two scans together to make one full model. Once scanned, the image can be converted into a STL file format, in-app, which could then with some cleaning be 3D printed.

On the big screen of the EyeCue booth at BETT 2019, plasticine models made by visitors were scanned, then brought to life in virtual reality (VR). If the program senses two legs, the scanned model will walk like a human, and if it senses four legs, the animation will move like a four-legged animal.

Ran Kraftory, CTO, described how Qlone has been used in education to date, detailing the Fort Vancouver Virtual Reality project, where students scanned real-life museum artifacts, then recreated the museum in VR. The project was led by John M. Zingale of MERGE, a Canadian organisation that specializes in introducing VR and AR into classrooms.

Because every student was given an iPhone to take around the museum, they could each take an active role in the project. As a result, they were more engaged with the technology and the lesson.

Rapid Electronics, a UK distributor of electronic components and educational resources, has a novel idea for increasing interest in 3D printing – drone competitions. The Airgineers STEM Drone Challenge encourages students to 3D print and race their own micro-drones, using custom designs. The aim is to get multiple schools interested in CAD modelling, due to the competitive element.

“The drones take a maximum of two hours to 3D print, making them feasible for the classroom,” said Chris Calver, Education Manager at Rapid Electronics.

As a base, Rapid Electronics offers a design for the 3D printed drones that is intentionally flawed; it is too heavy, and the camera does not fit properly in the frame, among other problems. This is to encourage students to make modifications to improve the drones, and therefore makes the competition one of design skill, rather than flying skill. Calver said that this would help students get to grips with CAD software in an appealing context.

When asked how educators are responding to 3D printing in classrooms, Calver said,

“It’s not uncommon for 3D printers to be used reasonably badly,” and highlighted the importance of an engaging project to gently break teachers and students into 3D printing.

Getting kids to DIY on 3D printers

In the minds of some 3D printing specialists, the way to interest students and teachers is to understand 3D printing devices themselves – by building them. JoyPlace, a Korean startup that makes self-assembly 3D printers for schools, showcased its Cremaker Joybot at BETT 2019.

According to Jae Sang-Ha, founder of JoyPlace, Cremaker JoyBots are designed to be simple enough for a 10-year-old to assemble.

The Cremaker began life as a crowdfunding project in Korea. The company has showcased its 3D printers in parts of Asia including China, as well as Russia, but never before in any other European country. JoyPlace will launch a Kickstarter later this year, and is looking for a partner to sell Cremaker 3D printers in the UK. They currently sell at $100 and the company have sold 200 units in Korea.

Alternatively, 3D printing could be more interesting to schools if they adopted full Fab Labs, as opposed to just incorporating single 3D printers into classrooms. This would allow students to complete projects that cannot be completed with a 3D printer alone – for example, textiles projects featuring 3D printed accessories.

That is, at least, is the thinking from FabLab Factory, a Belgian provider of 3D printing workspaces, which parked its “STEAMachine” mobile fabrication lab on the floor at BETT 2019. Inside the fabrication laboratory was a 3D printer alongside other machines for making complete items, such as a sewing machine, CNC milling machine and a vinyl cutter.

FabLab Factory believes it is important for students to be able to finish a design in one lab, in order to fully appreciate the value of 3D printing. The company’s aim for education is to introduce fixed digital fabrication labs into school libraries. They offer a range of fabrication libraries known as “FabLib”, including digital fabrication tools, learning materials and training programs from starter to advanced levels.

A somewhat unexpected presence at BETT 2019 was RPS, UK manufacturers of digital machines for industry. RPS was mainly there to showcase the 3D prints from its NEO800 large-format SLA system. By the company’s own admission, this model is unlikely to be installed in schools, due to its size and cost.

On the other hand, the very large, high quality resin 3D prints were undoubtedly gathering positive attention from attendees at BETT 2019. Perhaps some impressive examples of what 3D printing can achieve will inspire teachers to educate themselves about 3D printing, so they will be better equipped to bring it into their classrooms.

From talking to 3D printing companies at the exhibition, the overall picture is that teachers struggle with 3D printing technologies, decreasing their level of enthusiasm. It takes teachers who are willing to experiment, and potentially be the first educators in their institution to embrace 3D printing, to change this trend.

The best 3D printing innovations deserve recognition. Make your nominations now for 3D printing start-up of the year, Innovation of the year and more for the 3D Printing Industry Awards 2019.

For an abundance of stories on 3D printing and education, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows The Qlone 3D scanner for iPhone by EyeCue.