Visiting Israel, and especially the Rehovot area where what today is Stratasys, and yesterday was Objet was created, I gained a better understanding of what the history and implications of Objet’s trademark polyjet technology are.

What today is the only inkjet technology capable of producing multimaterial, multidensity and multicolor parts was created as a logical evolution of large format digital color 2D printing. Many of the people that today are leading Stratasys, including current CEO David Reis, were part of large format 2D printing company Scitex, which still exists today as HP-Scitex. They then used the same piezoelectric inkjet printing technology, adding a new dimension and going on to found Objet.

Some stayed all the way to the Stratasys merger, others went on to invent new ways to 3D print. One of these is Xjet’s nano particle jetting. Another is Massivit’s Gel Deposition (3D) Printing. This technology, in a way, represents the closing of a circle, since it once again focuses on large format printing, just like Scitex did, only with an additional dimension to it.

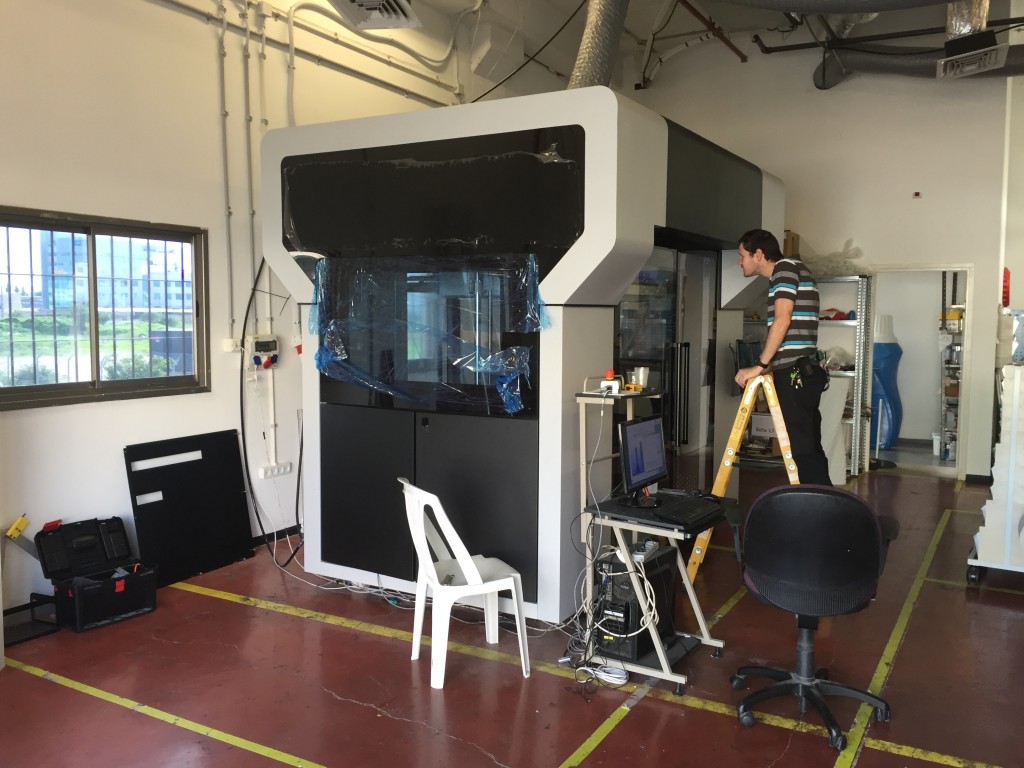

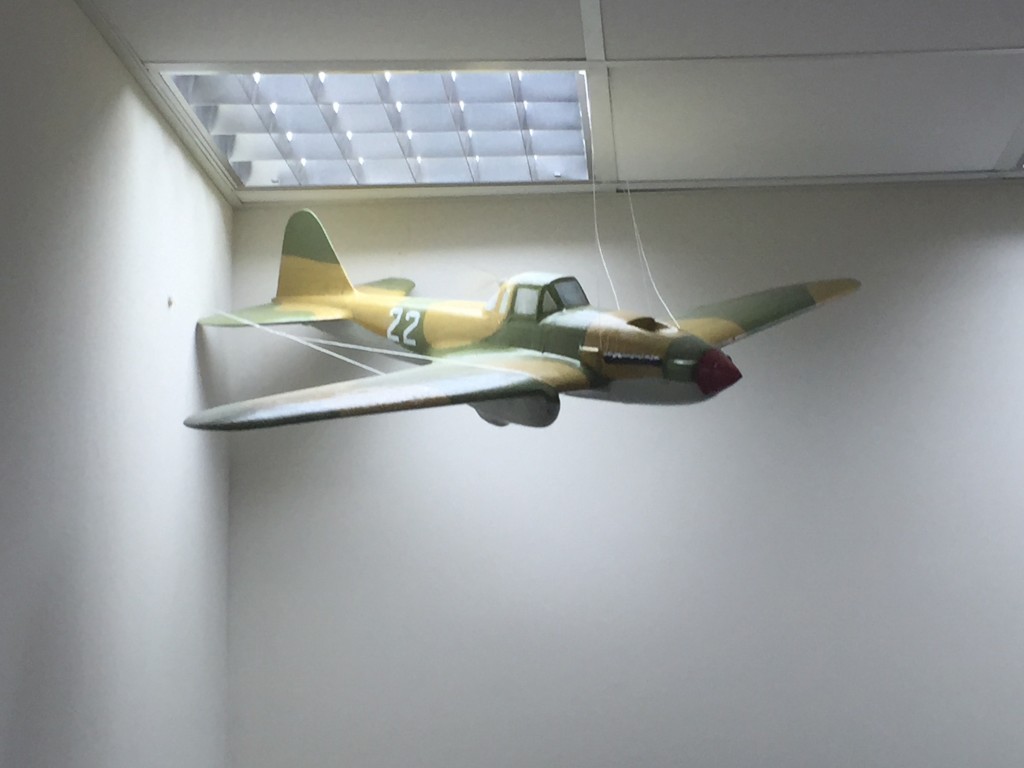

I first heard about Massivit’s technology last year and I immediately marked the company down for a visit on my next trip to Israel. I finally visited Massivit’s factory in Lod, a small industrial town not so far from Rehovot, just as the company sold its first commercial machine and is getting ready to set up a solid international sales network. In Lod, I found the Massivit’s factory by looking for the full size Strati replica parked in front of it.

“The three founders, Gershon Miller, Moshe Uzan and Igor Yakubov, established Massivit in June 2013. All three of them came from the large format 2D printing sector”, says Lilach Sapir, Massivit’s VP of marketing, who agreed to meet with me. She also has a past in Scitex. “Gershon Miller, who founded Idanit in 1996 and sold it to Scitex in 1998, is one of our biggest investors and has also been supporting us with tech and business guidance.”

Now Massivit is almost ready to hit the market at full force. The website has been updated and redesigned. The commercial presentation of the Massivit 1800 is set to take place at Drupa, one of the largest 2D Printing shows in the world, which will take place at Dusseldorf Messe next May.

This year, for the first time, Drupa will dedicate a large space and many conference to 3D printing and to how large 2D printing service providers can implement and offer 3D printing technologies in their business. Giants like HP and Ricoh are rumored to make big announcements at the show. Judging by what they have achieved so far, Massivit is perfectly positioned to ride this new, very real trend, in 3D printing adoption.

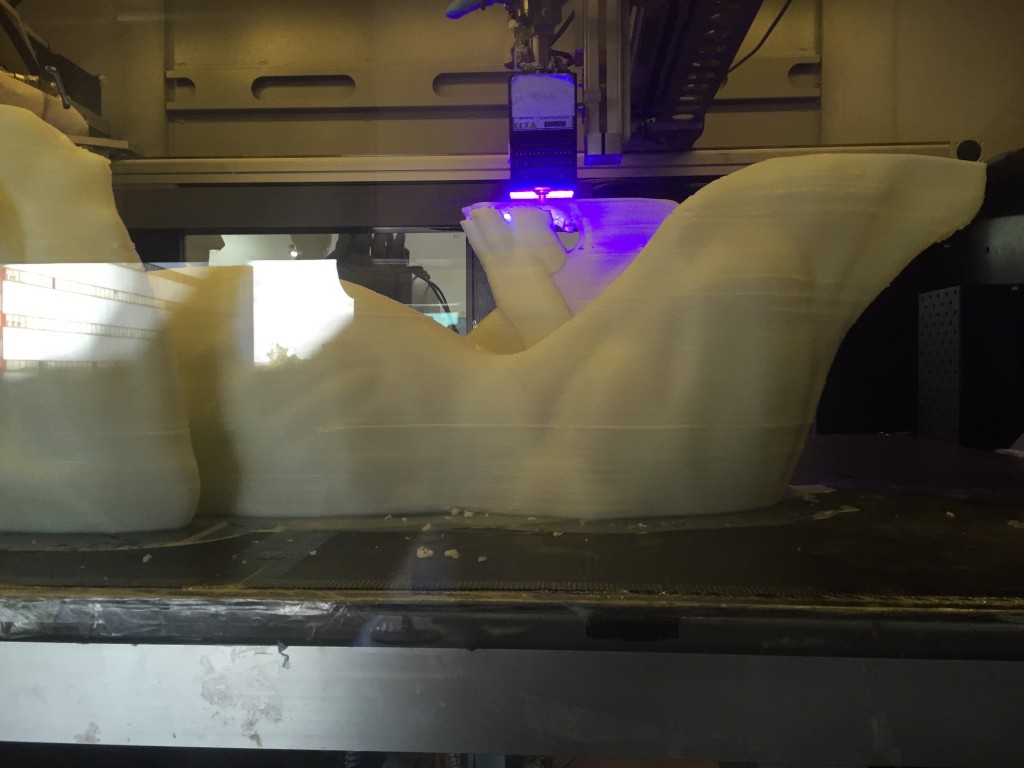

So what can the Massivit 1800 do and how does it do it? First of all it has an enormous printing volume of 1200 x 1500 x 1800 mm. This means that it can 3D print a person-size object in one single print. Even two different persons at the same time, since it has two print heads. It can do this at the incredible printing speed of 1000 mm/s.

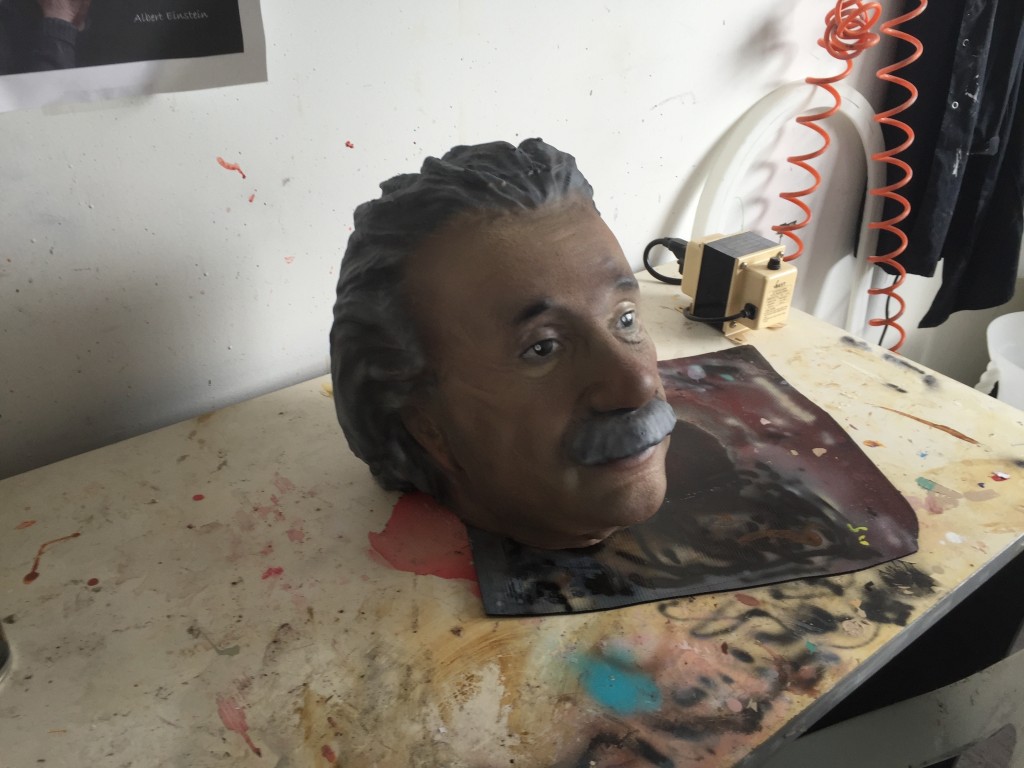

Seeing print is impressive, in just a few minutes the machine added several centimeters to the large objet is was printing. Of course this also means that the layers are very thick, up to 3 mm. This is a relative factor though, since the objects are very large and they still require a finishing process. By applying thick paint or even metal finishes the layer lines become much less visible.

They reason it prints so fast is that it does not have to use heat to melt plastic. It uses a cold process in which it deposits a gel material which is immediately cured by a UV-source positioned right on the print head. The experience with UV-curing of a photopolymer material is actually the only connection with polyjet technology. The rest is very similar to a super-fast FDM vector movement. “We set out to do the same thing that we did in the 2D printing world, betaking an existing process and making it large,” Lilach explains. “However this is no copy and paste project: we had to reinvent 3D printing.”

One of these “reinventions” is that the layers are cured together, which means that the molecules of different are bound together much more inextricably. This also means that there will never be holes between layers and, if a GDP printed object were to crack (the hardened plastic of the first material available is rigid, brittle and not particularly elastic), it would do so across the layer lines and not alongside them.

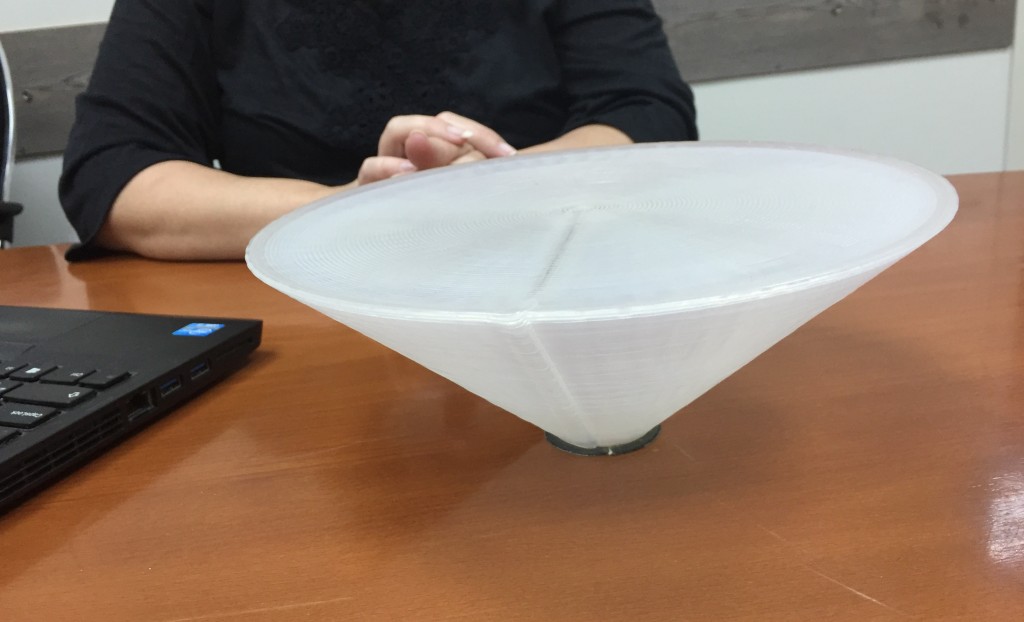

The biggest implication,though, is that supports are almost completely done away with. Lilach showed me parts where the entire top cover was 3D printed with no supports at all. In some particularly complex geometries, supports are added but only as a thicker double layer, not touching the build plate.

The current resin material used by Massivit (more are in development) is not ideal for end use products but it is perfect for display items. It is a bright, translucent, white material which can also be used for 3D printed light effects. At around $100 per 1 Kg it is also extremely affordable, compared to any other resins for large size printers on the market.

Now Massivit is preparing the next phase. The company is ready to ramp up production since it has been relying on Flextronics, the second largest global Electronics Manufacturing Services company (after Foxconn) for all commercial machine production. This is a huge advantage since it is not so common that a giant like Flextronics accepts work with a startup company. “They have done extensive tests and research before accepting to take on the manufacturing,” says Lilach “They have very high expectations.”

The future looks bright and at this point it is more a matter of finding the best partners rather than selling as many machines as possibile. Massivit just signed a distribution agreement for the US market with Prisco Digital and is already talking with potential partners in Europe. The South American and Asian markets will come in a second phase. Whatever comes next, it is going to be Massivit.