Cleaning and surface finishing systems manufacturer DyeMansion launched its new Powerfuse S PP system designed for smoothing 3D printed polypropylene. The Powerfuse S PP, according to DyeMansion, is the first green vapor polishing solution ideal for high industrial manufacturing and surface improvements far above aesthetic values to smooth 3D printed PP.

DyeMansion’s Powerfuse S model is compatible with flexible and rigid materials on the market, including PA, TPU, ULTEM, and others. On the other hand, Powerfuse S PP is designed for processing polypropylene.

“After seven years in business, developing workflow solutions for our customers, I’m thrilled to see that the factory of the future is becoming a reality, also thanks to our latest products. Together with our customers and partners, we are building different factories for high-volume applications around the world. At Formnext, we show how everyone can implement our solutions in their own factory. Connectivity, automation, and reproducible quality are the prerequisites to successfully future up your factory,” said Felix Ewald, CEO, and Co-Founder of DyeMansion.

DyeMansion 360° Digital Services

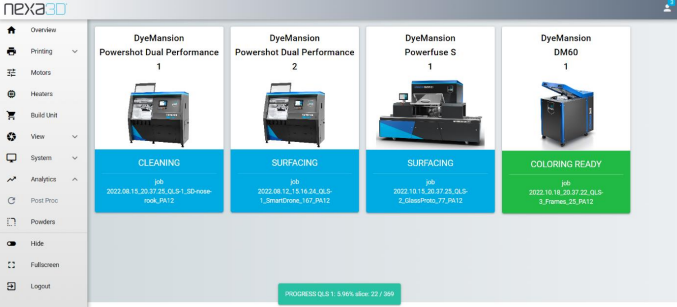

DyeMansion has revealed its first digital product family, the DyeMansion 360° Digital Services. The product line includes DyeMansion Remote Service, DyeMansion Data Connect, and DyeMansion Workflow Center.

The DyeMansion Workflow Center is a browser and cloud-based web application. DyeMansion has chosen Siemens MindSphere as its product framework. It provides live monitoring, custom alerts, and run history that is prepared to use immediately via plug-and-play. Customers can monitor and analyze their own workflow – according to the company.

DyeMansion Data Connect provides MES/ERP systems with the on-site machine and process data. According to DyeMansion, the Remote Service allows more effective collaboration through targeted support, maximum uptime via direct troubleshooting, and reduced resources with a “quick and effective” remote service.

The company presented a live demo of the DyeMansion Workflow Center at Formnext 2022. As a post-processing partner, the company has also joined Materialise’s CO-AM software platform in its efforts to advance serial AM production. The Print-to-Product workflow can be easily accessed on CO-AM with a standardized OPC-UA interface, says the company.

DyeMansion + Nexa3D – a strategic partnership

“Nexa3D is driving innovation to digitize the supply chain sustainably by making the world’s fastest polymer 3D printers affordable for professionals and businesses of all sizes,” said Kevin McAlea, COO of Nexa3D.

DyeMansion and Nexa3D revealed a strategic collaboration for automating additive manufacturing workflows from printing to finished parts. This collaboration will make use of Nexa3D’s QLS 820 printer’s throughput capabilities, DyeMansion’s automated post-processing hardware, as well as the printer’s Siemens PLC integration and powerful NexaX for QLS manufacturing software.

“It’s only natural that we would partner with DyeMansion, the leading provider of automated post-processing solutions for powder bed fusion, to ensure that our industrial customers can leverage high-throughput manufacturing capabilities from end-to-end as well as reduce their total cost of operation,” added COO of Nexa3D.

DyeMansion believes this strategic partnership will enable users in managing productivity and product quality easily.

Partnership with HP leading to the production of new materials for its post-processing platform

HP is collaborating with DyeMansion to provide connected post-processing workflows for finishing and coloring white parts manufactured utilizing the new HP Jet Fusion 5420W.

DyeMansion claims to provide a variety of vibrant colors with high color consistency, as well as distinct finishes relying on application needs. The businesses showcased a variety of final parts at Formnext to illustrate their surface finishing and coloring capabilities.

“As an experienced MJF part provider, we are excited about the new possibilities that can be achieved with white MJF parts enabled by HP 3D HR PA 12 W material. We see a huge potential, especially within the healthcare segment, to increase customer satisfaction with very good detail resolution and the new coloring and surface options, provided through systems from DyeMansion, that this new material brings to the market,” said Henry Lundell, Senior Business Development at Prototal.

Furthermore, Lubrizol also approved the Powerfuse S for smoothing semi-rigid TPU materials. The ESTANE 3D M95A TPU, created with HP Multi Jet Fusion, is skin sensitivity certified and dyeable according to DyeMansion.

DyeMansion published a new whitepaper titled “Optimising Post-Processing for Ultrasint TPU01” in collaboration with BASF, concentrating on depowdering, vapor polishing, and dyeing of Ultrasint TPU0, printed on HP Multi Jet Fusion. The DyeMansion booth at Formnext featured finished lattice components from BASF and other material suppliers, as well as the white paper.

Moreover, ALM, a new materials partner, is anticipated to supply Stratasys’ new SAF PA12 powder for the H350 3D printer. The powder has been validated with the Print-to-Product workflow, and parts made with it were displayed at the firm’s respective booths.

Elsewhere, DyeMansion has added twelve additional sales partners and nine new production partners since Formnext 2021. The total number of partners now stands at 85. With Nutechnologies in Romania, Dynagraph in the UAE, Energy Group in Italy, 3Dreams and Mafil in Israel, and Yokoito in Japan, the company is expanding into new markets.

Yokoito CEO and founder Yutaro Nakajima-san said: “Japan is historically a country that attaches great importance to product quality. Hence in Japan, the layer lines and unstable quality in post-processing have hindered the widespread adoption of 3D printing technology for many years. DyeMansion has the core technology that solves these problems, and we believe that if the technology becomes widespread, PBF as a manufacturing technology will advance rapidly in Japan.”

Follow this link for all the Formnext 2022 news.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Feature image shows DyeMansion’s motto “Future Up Your Factory”. Image via Dyemansion.