Dr. Thirumurugan S V Mahadhevan, is a medical consultant and healthcare solutions manager at Next Big Innovations Lab. With a background in dentistry, and masters degrees in pharmaceutical drugs, medical devices and nanomedicine, Dr. Thirumurugan S.V.M. shares views on the future of 3D printing across healthcare.

The future of 3D printing by Dr. Thirumurugan S V Mahadhevan

Innovations in the technology of 3D printing and scanning have been tremendous. The hype that was already being created in 3D printing is huge and the R&D is happening to fulfil the expectations in different parts of the world.

Though the technology erupted in 1980’s, 3D printing for healthcare has been getting familiar in the last decade. Let us see how, across all areas, 3D printing of healthcare can have a bigger impact in coming years.

Bio-printing

Whenever the words “3D printing in healthcare” are uttered, most people will ask, “is it possible to 3D print an organ like heart or brain?” These are possible in the future, but it will take decades at least as it involves lot of complexity to design every critical part, including cells, tissues, nerve while keeping it alive and fully functional.

Scaffold printing is widely catching up and it is a cost cutting measure for pharmaceutical companies by reducing animal and toxicity tests while being the anchor to create tissues and organs in future. Hydrogels and bio-inks will be developed, so that most of the researchers will involve in R&D activities. Research is being done in most countries including USA, Europe, Japan, China and India.

Personalized drug printing

FDA approved 3D printed drug for epilepsy (Spritam) is commercially available, where the pill dissolves in less than 5 seconds with a large dose. This technology can be utilised to make more lifesaving and essential drugs to reach the systemic circulation faster in large and various drug dosages.

For example, if a prescription includes an antacid, anti-biotic and a painkiller to be taken, a single 3D printed drug can be made in such a way considering his/her weight and disease progression. The pill can be designed in a controlled way to decide on where, when and to what extent the drug needs to be released. This technology will help in creating drugs in a personalised way while increasing efficiency and reducing the over dosage complications in a ‘One pill for all’ concept.

Smart prosthetics

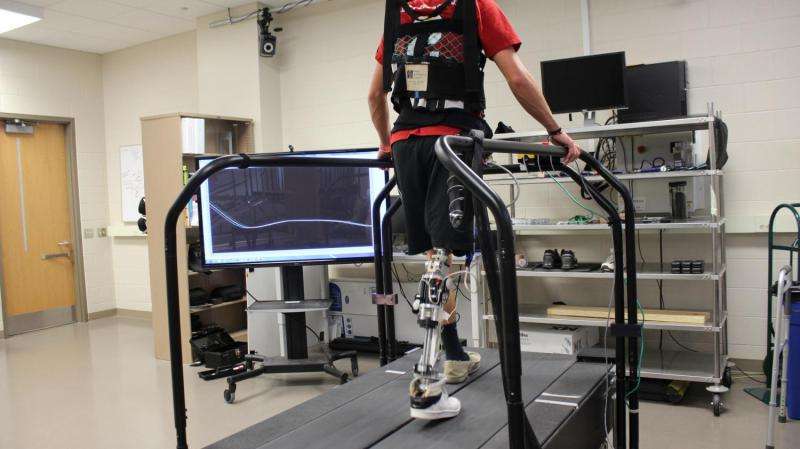

Gone are days when an amputated person waits for months to get their prosthetic extremities. Combining 3D printing and 3D scanning can help get a finished prosthesis in a few hours. These technologies helps make any prosthesis very accurate, highly durable and aesthetic too.

Furthermore, 3D printed prosthetics are being incorporated with smart electronic chips or sensors to make them fully functional, at a very low cost with less waiting time. Developing better 3D printed prosthetics with advanced sensors will create revolution in Smart Prosthetics. Even skin grafts which perfectly matches the exact skin tone can be 3D printed.

Nanomaterials

The usage of nanomaterials will have a great impact in every discipline. These materials can replace stainless steel and other elements with lesser weight and enhanced properties. Carbon fibre reinforced implants showed better osteointegration, toughness and flexibility for Knee replacement implants.

Likewise, more medical devices and smart sensors will be developed in accordance with 3D printing to evolve efficient diagnostic devices and implants.

Dental

Dentistry is one of the discipline which utilises 3D printing technology to its fullest. Stratasys and EnvisionTEC are the leading companies in dental 3D printing.

The 3D scanner, 3D printer and 3D software combined makes the requisite for Digital Dentistry. Crowns, bridges, wax burnouts, implants and denture bases can be already made in 3D printers and the procedures will be done in hours, fulfilling demand rather than waiting for days. The development of new resin materials will replace almost all conventional lab procedures with rapid production and faster delivery.

Medical

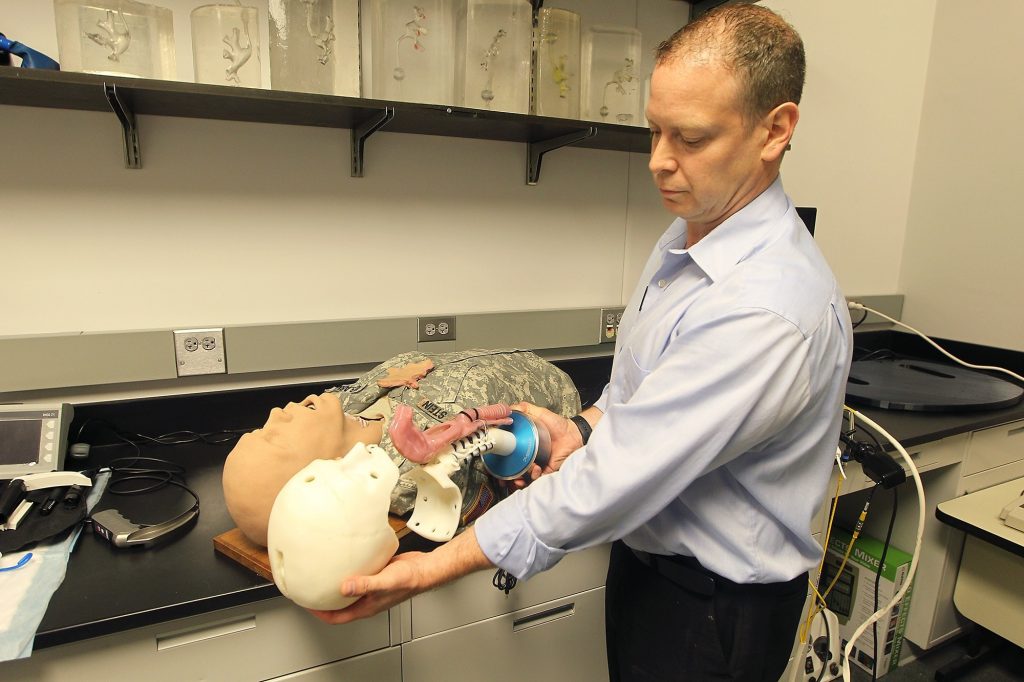

3D printing will be the best available technology for surgical planning, teaching and training purposes. Printers like Stratasys have the capability to produce patient specific organ models obtained from the diagnostic images.

It is possible to make organ models with multiple colours for critical structures, transparent models and structures mimicking the natural consistency and texture. Blood vessel models can be 3D printed, which gives the exact feel of real blood vessels. The teaching and training through these models will overcome the issues associated with Cadaver availability. Realistic surgical simulators will be the educating platform for everyone in coming years.

Challenges

One of the biggest hurdle in the development of 3D printing in healthcare will be on the regulatory and patenting aspects. Getting an approval from the regulatory bodies like FDA and EMA takes time and it is a rigorous procedure.

The cost is another big issue which makes 3D printing in healthcare out of reach in most countries. Most of the implants and other drugs will be commercialized after going through clinical trials it will take minimum of 10 to 15 years. Most of the patents are already pending and there will be a revolution of 3D Printing in Healthcare industry in the coming years with the support of regulations.

This is an article from the 3D Printing Industry thought leadership series looking at the future of 3D printing.

If you’d like to give your perspective on the future of additive manufacturing or trends in the 3D printing industry, then get in touch.

For further insights into the future of 3D printing, sign up to our newsletter and follow our active social media channels. Let us know your thoughts about this perspective on the future of 3D printing in the comments below.

More information about ALTEM TECHNOLOGIES and Dr. Thirumurugan can be found here.

Featured image: Dr. Thirumurugan S V Mahadhevan, provided by the author.