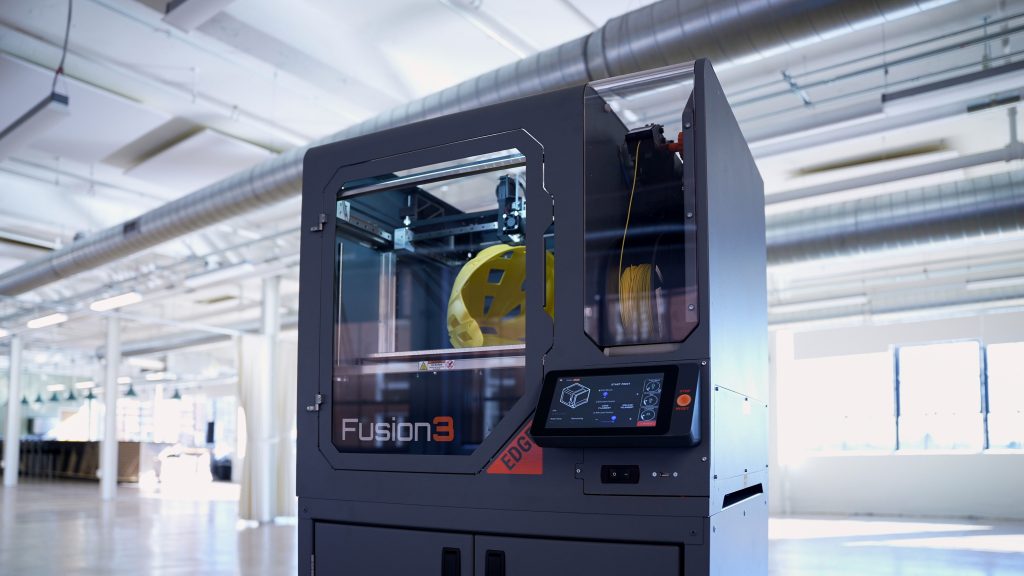

3D printer manufacturer Fusion3 has announced the launch of its new EDGE 3D printer.

Designed to rival pricier industrial-grade competitors, the professional FFF system aims to combine speed, precision, and ease of use in one comprehensive package. The EDGE also prides itself on its sizable build volume and long list of material capabilities, enabling users to 3D print filaments such as PC, PP, Nylon, TPU, and even fiber-reinforced composites.

Kate Padgett, Fusion3’s Founder and CTO, said, “EDGE encapsulates Fusion3’s nine years of industry experience, accumulated feedback from customers, and our vision for the changes needed to drive mainstream, commercial adoption of FDM 3D printing.”

FFF 3D printing with Fusion3

Based in North Carolina, Fusion3 has been developing professional FFF 3D printers for commercial, education, government, and military customers for almost a decade.

The new EDGE joins a long line of systems built for high-performance applications, the latest of which is the company’s F410 3D printer. Priced at $4,999, the machine sports a 355 x 355 x 315mm build volume and a choice of three interchangeable print heads. The firm has also previously offered the F400 and F306 3D printers, both of which are now discontinued.

To complement its extrusion-based machines, Fusion3 also has its own slicing software called REACTOR. The program is powered by Danish R&D company Create it REAL’s REALvision slicing engine.

The Fusion3 EDGE

The firm’s new EDGE 3D printer packs a build volume measuring 355.6 x 355.6 x 368.3mm, providing ample space for larger part production. Complete with Fusion3’s F-Series control technology, it features a number of upgraded motion control components such as new linear rails, Gates 2GT2 belts, and fine-tuned stepper motors. According to the company, this allows the system to print at up to 200mm/s for certain materials.

Fusion3 has also integrated its own patent-pending ANVIL print head system into the mix. Coupled with the firm’s V3 extruder, the assembly leverages a surgical steel print tube instead of a conventional screw-in nozzle, which reportedly offers faster print speeds and improved wear resistance for abrasive composite filaments. Additionally, Fusion3 claims the ANVIL print head is more robust and easier to maintain than a traditional counterpart. The maximum nozzle temperature clocks in at 320°C.

Looking inside the 3D printer, we have a heated build chamber capable of 70°C and ¼” aluminum print bed with a glass surface (max. temp. 145°C). Customers also have the option to add in a magnetic build plate with an assortment of magnetic print surfaces, making part removal a breeze.

Furthermore, the EDGE comes equipped with a new bed leveling system that utilizes an ultra-light touch probe to “ensure a near-perfect first layer for each print”. On the software and electronics side, there’s a 64-bit ARM processor with a 7″ touchscreen providing access to the user interface. The printer’s control system comes complete with remote print management capabilities and even reminds users of recurring maintenance tasks.

Technical specifications and pricing

Below are the technical specifications for the EDGE 3D printer. The system is available to order now for $6,999.

| Build volume | 355.6 x 355.6 x 368.3mm |

| Print speed | Up to 200mm/s |

| Max nozzle temp | 320°C |

| Max bed temp | 145°C |

| Max chamber temp | 70°C |

| Touchscreen | 7″ |

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Fusion3 EDGE. Photo via Fusion3.