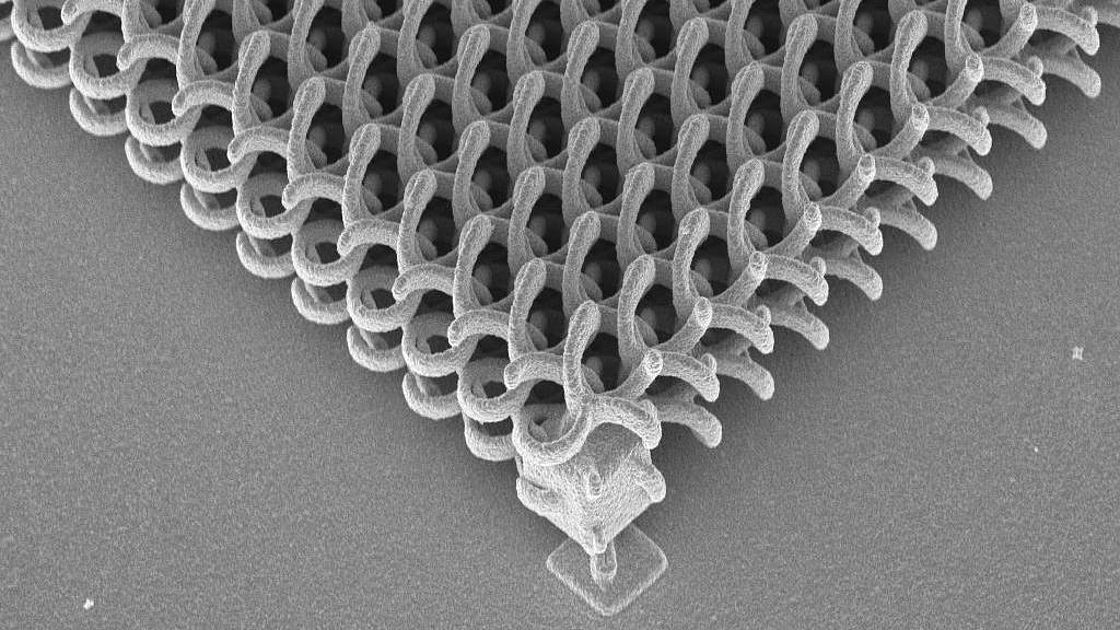

Scientists from the Fraunhofer Institute for Microengineering and Microsystems (IMM) in Mainz, Germany, are developing a novel process using multiphoton lithography to produce nanoscale structures on metal 3D printed parts.

As part of a Federal Ministry of Education and Research (BMBF) funded project dubbed “LAMETA”, the IMM team are aiming to achieve parts with features smaller than the resolution of those produced using Direct Energy Deposition (DED) processes.

“The generation of tiny structures with scales in the nanometer range is becoming increasingly important in many technical applications,” stated Dr. Thomas Klotz Books of Fraunhofer IMM and Manager of the LAMETA Project.

“If we extend the structures into the third dimension while simultaneously reducing the size of the structure to the order of magnitude of the wavelength of light, new interesting phenomena can be addressed.”

Multiphoton lithography vs. Direct Energy Deposition

According to the Fraunhofer IMM researchers, in order to scale down to nanometer resolutions, two-photon absorption in combination with commercially available metal precursors must be used. Two-photon absorption occurs within a transparent material at the wavelength of a laser used during the multiphoton lithography method.

Contrarily, DED uses an electron beam or a high power laser beam projector to melt wire feedstock to build 3D structures. This process takes place in a sealed chamber filled with inert gas to control the material properties. The scientists believe that parts created using DED mainly hold resolutions in the micrometer range.

Thus, a new multiphoton lithography process for additively manufacturing onto metallic substrates, enabling the production of unrestricted 3D printed nanostructures is needed. This may lead to the creation of optical components, as well as novel sensor elements.

Laser-sharp control

Within the proposed laser-based process, the scientists will be able to control light to selectively manipulate its interaction with radiated light and the electrons in a nanoscale metal framework. A new class of materials is also being developed for this process.

“We would like to demonstrate the concrete application potential of the method and thus open up new fields of application in the field of plasmonics,” added Books. This project is expected to be completed by 2020.

Voting is now open for the 2019 3D Printing Industry Awards.

Subscribe to the 3D Printing Industry newsletter and follow us Facebook and Twitter for the latest research in the field of additive manufacturing. Visit 3D Printing Jobs to find out more about opportunities in additive manufacturing.

Featured image shows nanostructure produced by laser-based deposition. Image via Fraunhofer IMM.