These are the days of the mad scientist — again. Thanks to the capabilities of 3D printing, combining old and new parts is as simple as finding the right CAD design followed by trial and error eventually leading to something called the Frankencamera. Shelley would be astounded by the repurposing of older models such as the analog camera, the Konica Auto S3 Rangefinder. Ollie Baker, the creator of the Frankencamera, resuscitated the original camera with 3D printing in such a way that it works as would the actual Konica model. The photographic jargon is best written by experts such as Baker, and his method proves highly accessible and instructional as a DIY project.

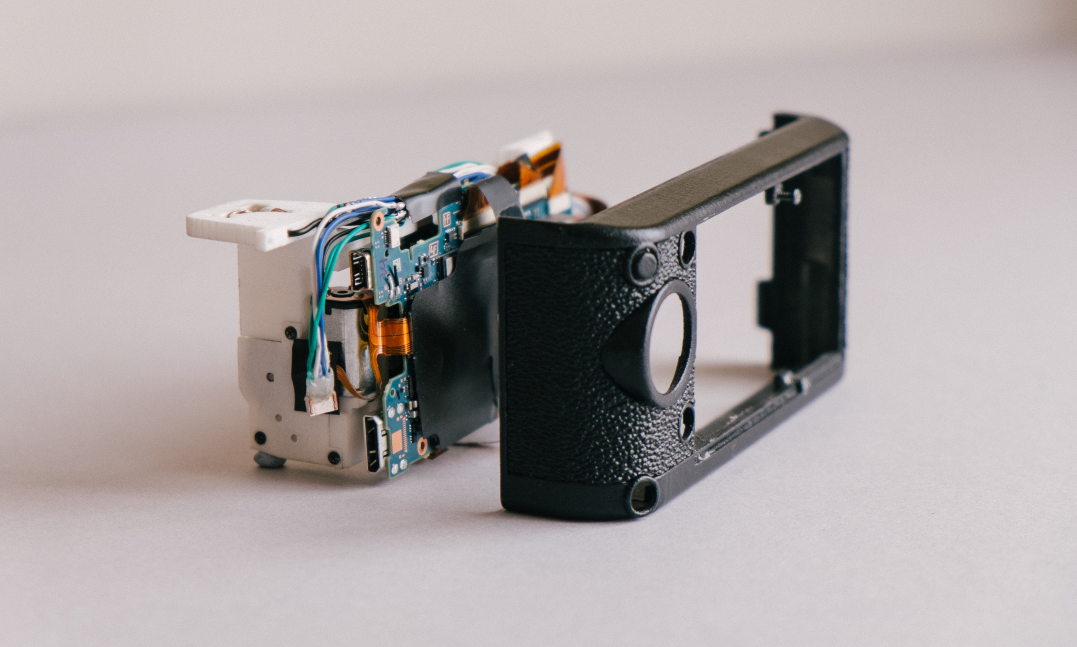

In order to begin the process, Baker assessed the vital components allowing the camera to function. Besides the typical needs such as the circuit board, sensor, SD card slot, and battery connector, it additionally required the motor module for the shutter attachment. Therefore, the camera needed three adjoining cogs within the design.

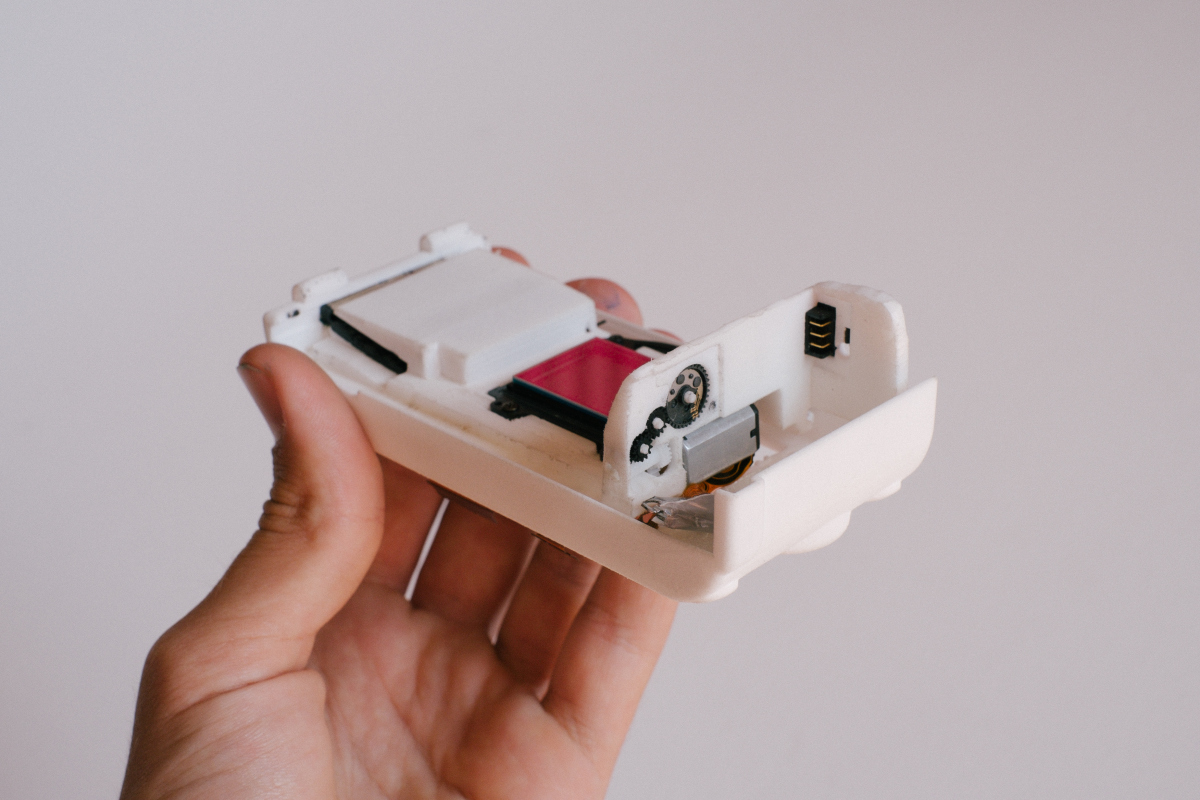

While the final quality nylon printing had to be outsourced to London, the groundwork was completed using a school 3D printer. Ollie began designing a CAD file for the necessary components with Solidworks and some Vernier calipers. In a decision that ultimately assuaged the pressing needs in one fell swoop, Baker decided to completely 3D print and replace the back of the camera. When the design took shape, its bottom part held the SD card slot, the sensor, the motor, the cogs, and battery. The top part held the screen and buttons and the main circuit board nestled between the top and bottom.

Not satisfied with what he had already printed, Baker outlines his final steps:

“I also designed a replacement ON/OFF mechanism in my final design which requires the film rewind wheel to be pushed down for the camera to turn on. This also held the design firmly in place. I also designed a replacement trigger which could house a miniature electronic switch which would be pressed as the trigger was being pressed down and released afterwards. This activates the digital sensor for the duration of the trigger being pressed (the digital camera being on the BULB setting), during which the film camera shutter is activated causing the sensor to be exposed as film would be.”

After some tweaking with the design, Frankencamera took shape and operates among other cameras. The final look leaves the creation nearly indistinguishable from the original camera, and is reported to function as it would in its old form. Unlike Victor’s creature, this Frankencamera will draw welcome attention for its form and function.