Spain-based 3D printer manufacturer Triditive has partnered with Taiwanese electronics firm Foxconn to develop a new metal 3D printer based on binder jet technology.

As of yet, details of the unnamed system are scarce but we do know that both firms are currently working on an initial prototype, as well as new materials for use with the 3D printer.

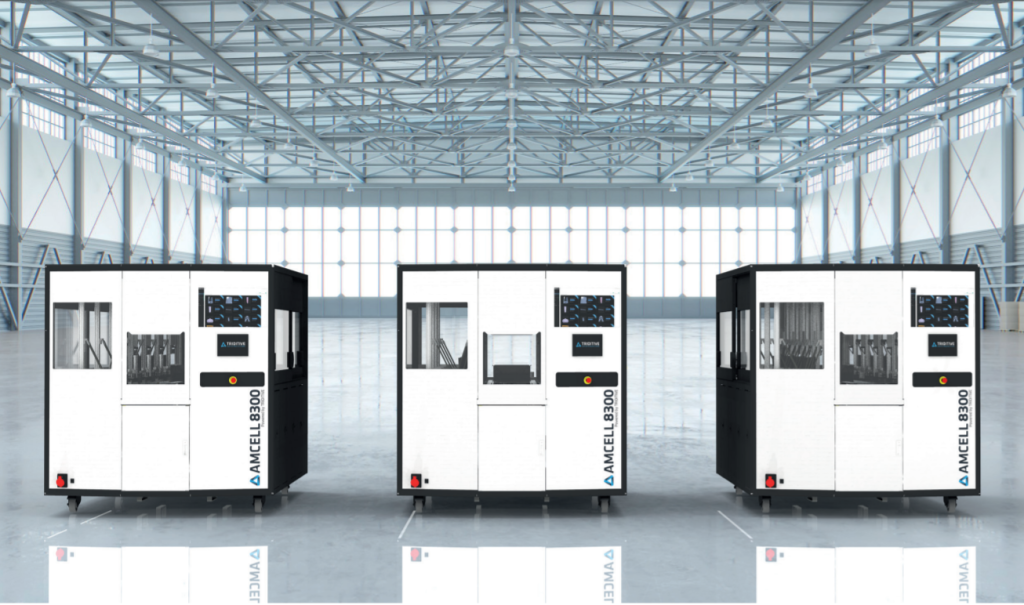

Triditive’s business is built around its patented AMCELL 3D printer lineup, which includes the AMCELL 1400 and AMCELL 8300. The modular systems are based on the company’s own AMD (Automated Multimaterial Deposition) technology, which combines a binder jetting module with several delta FDM modules to print metals, polymers, and even fiber-reinforced composites. Foxconn, on the other hand, is one of the largest electronics assemblers in the world, producing devices for the likes of Apple, Sony, Nintendo, Microsoft, and Intel.

Triditive is also collaborating with Tecnalia, the research center of the Basque Country, to develop custom binding agents for the process. According to the firm, it’s also working closely with German research organization Fraunhofer to select the metallic powders that will be compatible with the 3D printer.

Foxconn and Triditive state that the key selling points of their upcoming technology will be scalability and cost reductions, and it will be suitable for 3D printing complex end-use metal parts.

What is binder jet 3D printing?

Metal binder jetting is an inkjet-based 3D printing process that leverages a powder bed of metal feedstock. A high-precision printhead is used to spray carefully-controlled amounts of liquid binding agent onto the powder bed, which binds the powder into a solid layer. The bed is recoated and the process repeats itself layer by layer until a 3D part is produced.

As parts are printed surrounded by unfused powder, there is often no need for the use of support structures. Triditive also claims that any excess unfused powder in the build chamber will be reusable, further saving on materials costs.

Much like any 3D printing process, binder jetted parts also need to be post-processed, especially if they’re designed for end-use. Components that are fresh out of the build chamber are in their green state, meaning they’re brittle and fragile due to high porosity. They can be sintered in a furnace to burn away the binding agent (debinding) and increase the density of the part, improving its mechanical properties.

Triditive and Foxconn – a curious partnership

Although it makes sense for Triditive to take a shot at the binder jetting market, the involvement of Foxconn is a little more surprising. Foxconn has used 3D printing for prototyping applications for decades, but it’s never developed a 3D printer or 3D printing materials until now, meaning it’s officially entering the additive manufacturing space for the very first time.

In fact, back in 2013, Foxconn CEO Terry Gou told Taiwanese media, “3D printing is a gimmick. If it really is that good, then I’ll write my surname ‘Gou’ backwards.”

He went on to add that 3D printing was not suitable for mass production (Foxconn’s specialty) and that it didn’t have any commercial value.

So why the change in heart? Thanks to advancements in 3D printing technology, additive processes are now more viable than ever for high-throughput production applications. As such, Foxconn probably now sees 3D printing as a viable method of automating some of its more manual manufacturing and assembly workflows, even at mid to high volumes. Binder jetting, especially, lends itself to fast print speeds and large build volumes, so Foxconn’s batch production efforts may soon benefit from significant cost and lead time reductions.

Big names in additive manufacturing

Every so often, we see tech and manufacturing giants like Foxconn make an exciting investment in the 3D printing sector. Just last month, Seiko Epson Corporation (Epson), a multinational Japanese electronics firm specializing in 2D printing technology, announced the launch of its debut industrial-grade 3D printer. According to the company, the novelty of the machine lies in its unique flat screw extrusion technology, which allows the system to 3D print a wide variety of pellet materials.

Elsewhere, Mitsubishi Electric Corporation, a major manufacturer of electronics and electrical equipment, recently announced the launch of its own new metal 3D printing system. The upcoming AZ600 is a laser-based directed energy deposition (DED) system that’ll work by melting welding wires to 3D print near-net-shape metal parts.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Triditive’s AMCELL 8300 3D printer. Photo via Triditive.