Ackuretta is a professional digital light processing (DLP) 3D printer manufacturer from Taiwan’s Neihu District in Taipei City. The forthcoming desktop Diplo model was first previewed at Formnext in Frankfurt and adds to the existing Ackuray Series of enterprise 3D printers.

As the company’s flagship 3D printer, the Diplo 3D is powered by advanced projector technology, and brings a number of unique features to the additive market.

Dual print areas, double productivity

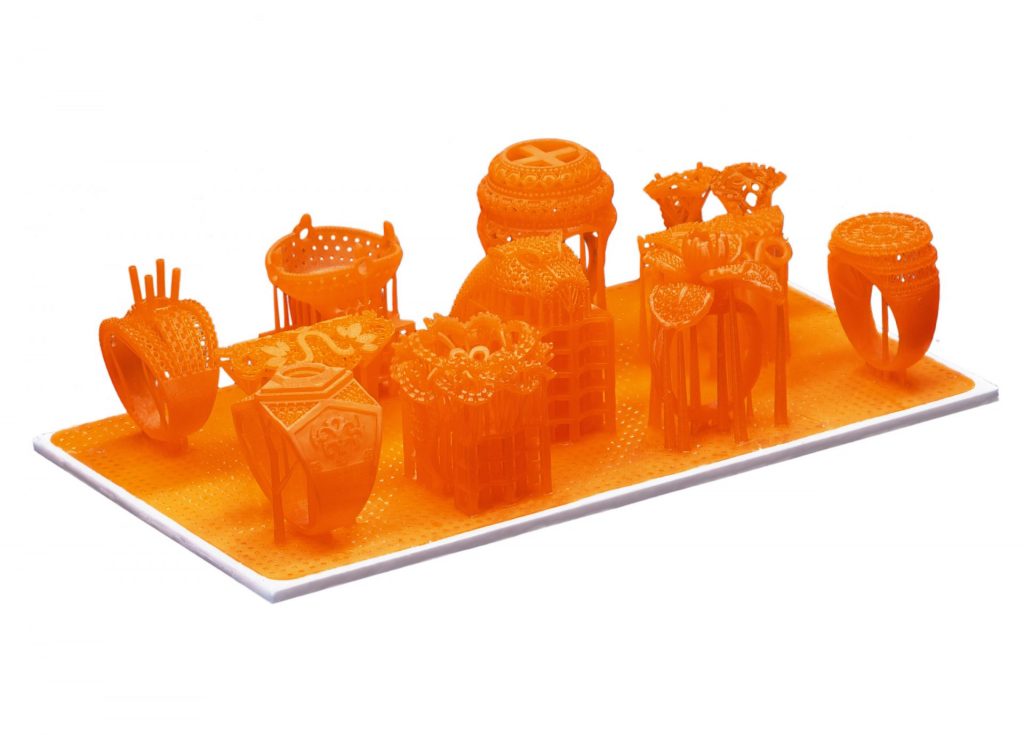

Ackuretta 3D printers are tailored for use in high precision areas of industry. Jewelry making, dentistry and engineering companies all benefit from the technology, and use the systems to make detailed prototypes, surgical guides, and a wide range of dental applications.

One of the unique features of the Diplo 3D is that it has two build areas. Each of the areas in the 3D printer measures 140mm x 78mm (X x Y), and is powered by Ackuretta’s patent-protected Multi-optical Reflective System (MORS).

Lucas Wiltse, commercial director of Ackuretta Technologies Pvt. Ltd. describes MORS as, “a breakthrough technology that utilizes a singular light-source to generate two build areas on one platform.” By offering this duality, users can control two different jobs at the same time, optimizing productivity by 200%, and bypassing what Wiltse believes is one of the main challenges of the industry, “With the introduction of DLP technology, we offered an advanced 3D printing solution that balanced the needs for high-precision at rapid speed,” he says.

“A common shortcoming for many users has been the inability to produce at large volumes. The MORS technology launched with the Diplo enables you to more than double the production of mainstream DLP printers while minimizing the costs associated with high-volume 3D printers.”

The system is capable of achieving a slice thickness of 5-100 microns (dependent upon materials) and can print up to a maximum height of 110 mm.

Accelerating innovation

To encourage innovation in the industry, and create an adaptable environment, all of Ackuretta’s 3D printers work on an open materials platform. The company has also developed its own line of Qura resins, and are committed to finding ways to be more environmentally friendly with recyclable materials.

QuraDENT is suitable for high accuracy, a fine surface finish, and a high dimensional stability in dental applications. QuraWAX is Ackuretta’s material suitable for the lost wax method of casting both jewelry and dental products. There is also QuraCLEAR, for transparent 3D prints, and QuraGP – an ABS-like material, for tough, chemically resistant applications.

Versatile control

The Diplo 3D printer can be operated with a connection to tablets, computers and smartphones. It can also be controlled using a browser-based console, or directly from system stored/USB loaded files. Such versatility makes 3D printing possible from virtually anywhere.

Items can also be previewed before 3D printing on an in-built, full-color touchscreen, which clearly divides the left and right print areas. Notifications on this interface, and in the browser-based control panel, also make the 3D printer easy to operate and troubleshoot for occasional/unfamiliar users of the technology.

Powered by Materialise

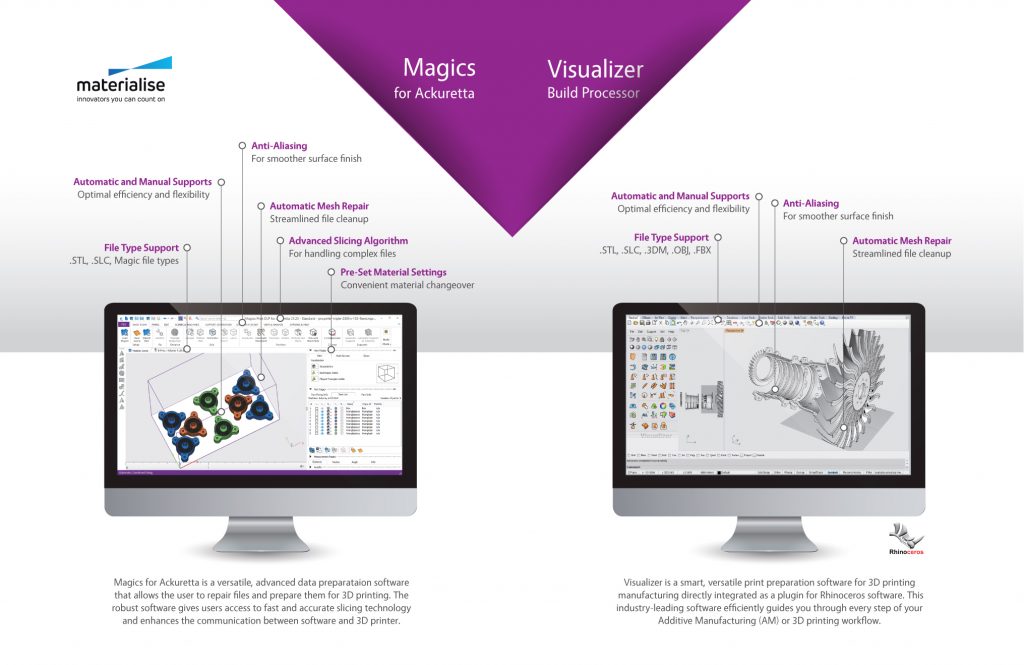

Materialise’s Magics software suite, Visualizer, and Inteware all run with the Ackuretta Diplo and Ackuray 3D printers. Dubbed “the world’s most powerful 3D print software” the Ackuretta Materialise package takes care of the digital design process. It helps users prepare files for 3D printing with preset materials profiles, surface finishing tools, mesh repair and advanced slicing for complex files.

The Magics platform accepts standard .stl format, .slc and Magics files. Whereas the Rhino powered Visualizer, that also provides automatic mesh repair and smooth finishing, is compatible with .stl, .slc, .obj, .3dm and .fbx files. Inteware offers dental professionals an intuitive, easy-to-use solution with the essential tools available.

“Another focal point for us has been software development,” adds Wiltse, “More intuitive, easy-to-use software is key for adoption of 3D technology across a wide range of industries,”

“This can also act as a catalyst for mass customization, personalization and mass manufacturing.”

One-stop 3D printer shop

Adding to user-friendly hardware, Ackuretta has composed a number of detailed user guides to support users of Diplo and Ackuray 3D printers. Divided into two categories, “3D printers” and “Post-processing,” the guides contain all the information necessary for users to efficiently set up their own machines, and clean/finish parts to a high standard.

The company also sells hardware kits, the starter kit to facilitate resin changes; and a finishing kit containing all the tools necessary to achieve a professional product.

Fast reaction to global trends

One of the main drivers of innovation in 3D printing is the demand for automation. In our interview with Ackuretta, Wiltse states that “The future of 3D printing is simple: users want to make a 3D model, and then directly use the part without cleaning, casting or polishing.”

To serve these challenges, Ackuretta is currently developing an automation module. This module can be directly attached to the Diplo 3D printer. It switches both the vat and build platform for clean versions that can be used to automatically start a new print job.

Up to 16 finished items can be kept inside the automation modules storage chamber, and there are 8 interchangeable vats to keep production going 24/7.

Wiltse explains, “The automation module further eliminates labor activity with features including scheduling, error detection, and print monitoring remotely,”

Furthermore “[it] allows you to realize your ROI within months by limiting downtime, decreasing labor costs and lowers the cost per part.”

Find Ackuretta’s 3D printers and products online here exclusively through the company’s official site.

To be the first with all the latest 3D printer releases, subscribe to the free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows the Diplo 3D printer. Image via Ackuretta